Infiniti G35 (V35) Sedan. Manual - part 556

EC-370

< COMPONENT DIAGNOSIS >

[VQ35HR]

P1238, P2119 ELECTRIC THROTTLE CONTROL ACTUATOR

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000000956764

1.

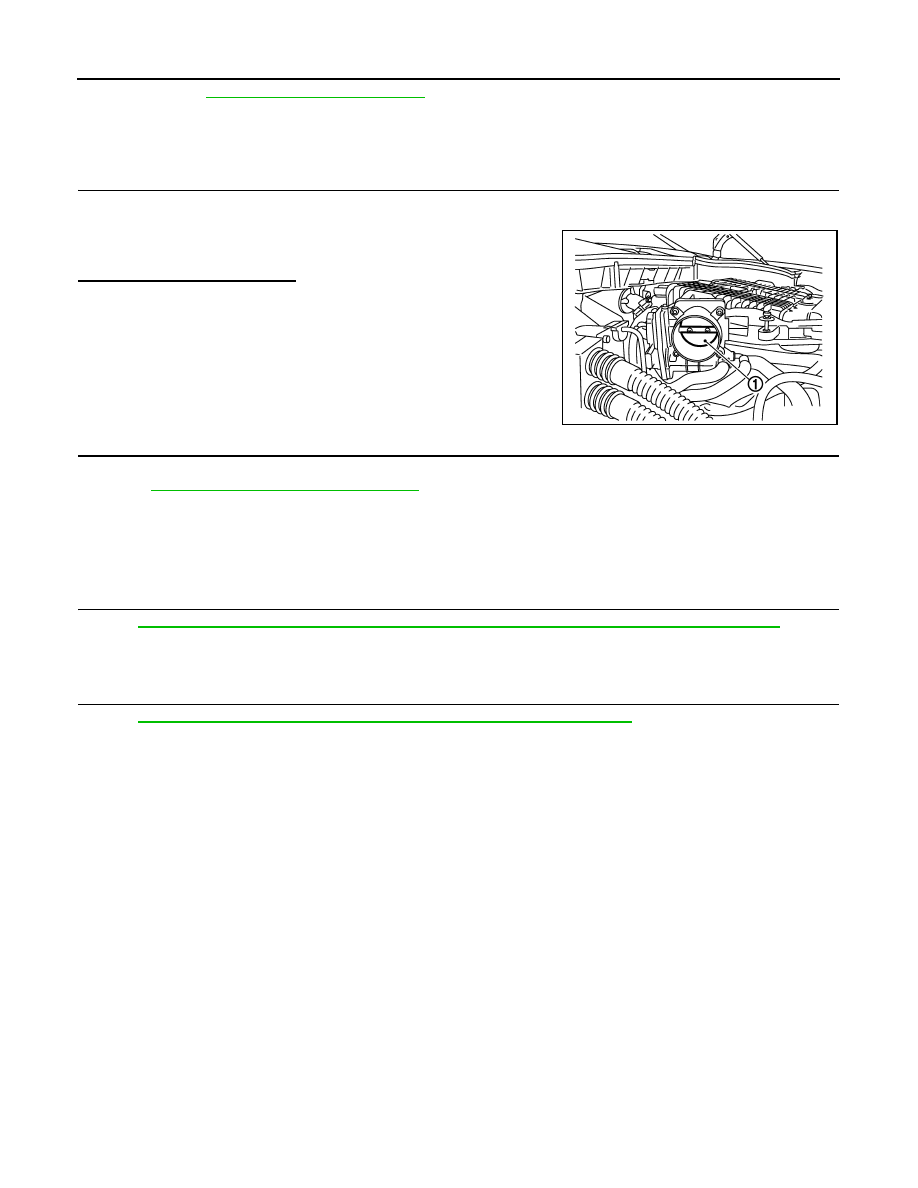

CHECK ELECTRIC THROTTLE CONTROL ACTUATOR VISUALLY

1.

Turn ignition switch OFF.

2.

Remove the intake air duct.

3.

Check if foreign matter is caught between the throttle valve (1)

and the housing.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Remove the foreign matter and clean the electric throttle

control actuator inside.

2.

REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1.

Replace malfunctioning electric throttle control actuator.

2.

Go to

EC-370, "Special Repair Requirement"

.

>> INSPECTION END

Special Repair Requirement

INFOID:0000000000956765

1.

PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

EC-18, "THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement"

>> GO TO 2.

2.

PERFORM IDLE AIR VOLUME LEARNING

EC-18, "IDLE AIR VOLUME LEARNING : Special Repair Requirement"

>> END

JMBIA0025ZZ