Infiniti FX35 / FX45. Manual - part 862

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PR-3

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

M

A

B

PR

N

O

P

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

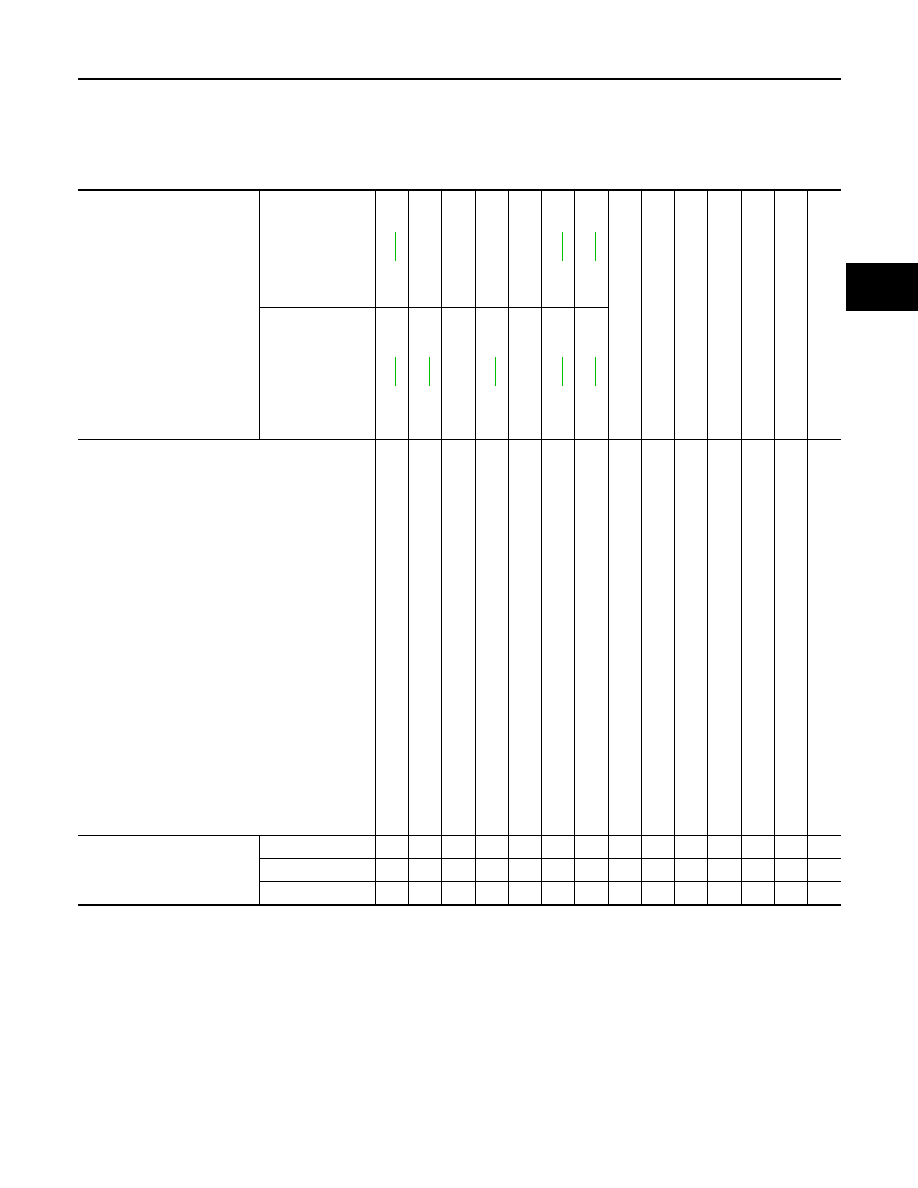

NVH Troubleshooting Chart

INFOID:0000000001327465

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×

: Applicable

Reference page

Front

—

—

—

—

NVH in FFD an

d RF

D

se

ct

ion

NVH in F

AX, RAX

, FS

U,

an

d RS

U

se

ct

ion

NVH in WT

se

ct

io

n

NVH in WT

se

ct

io

n

NVH in RAX

section

NVH in BR section

NVH in PS

section

Rear

—

—

Possible cause and SUSPECTED PARTS

Un

ev

en

rot

a

ti

ng

to

rqu

e

Cen

ter bea

rin

g

i

m

p

rop

er ins

ta

lla

tio

n

Exc

e

s

s

iv

e

c

e

n

ter

be

arin

g

ax

ia

l e

n

d

pl

ay

Ce

nt

e

r

b

e

a

ri

ng

mou

n

ti

n

g

(in

su

lat

or) c

rack

s,

da

ma

ge

or de

te

ri

ora

tio

n

Ex

ce

ssi

ve

jo

in

t an

gl

e

Ro

tat

ion

i

m

ba

la

nc

e

Ex

ce

ssi

ve

run

o

u

t

DIFFERE

N

T

IAL

AXLE

AND SUSPE

N

S

ION

TIRE

ROA

D

WHEEL

DR

IVE SHAF

T

BRAKE

STEERI

N

G

Symptom

Noise

×

×

×

×

×

×

×

×

×

×

×

×

×

×

Shake

×

×

×

×

×

×

×

×

Vibration

×

×

×

×

×

×

×

×

×

×

×