Infiniti FX35 / FX45. Manual - part 645

OIL SEAL

EM-97

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

OIL SEAL

Removal and Installation of Valve Oil Seal

INFOID:0000000001325734

REMOVAL

1.

Remove camshaft relating to valve oil seal to be removed. Refer to

2.

Remove valve lifters. Refer to

.

3.

Turn crankshaft until the cylinder requiring new oil seals is at TDC. This will prevent valve from dropping

into cylinder.

4.

Remove valve collet.

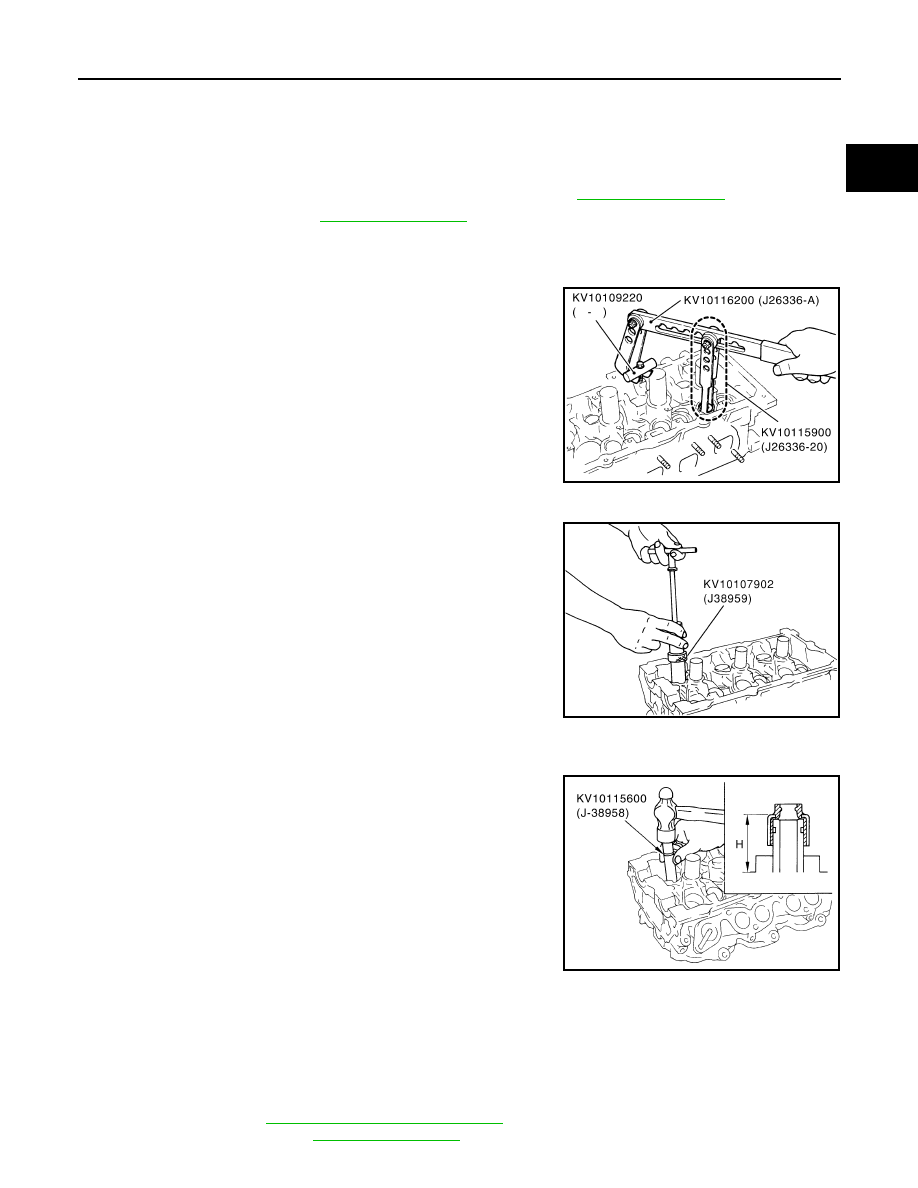

• Compress valve spring with the valve spring compressor, the

attachment, the adapter (SST). Remove valve collet with a

magnet hand.

CAUTION:

When working, take care not to damage valve lifter holes.

5.

Remove valve spring retainer, and valve spring.

6.

Remove valve oil seal using the valve oil seal puller (SST).

INSTALLATION

1.

Apply new engine oil on new valve oil seal joint and seal lip.

2.

Using the valve oil seal drift (SST), press fit valve seal to height

“H” shown in figure.

NOTE:

Dimension “H”: Height measured before valve spring seat instal-

lation

3.

Install in the reverse order of removal after this step.

Removal and Installation of Front Oil Seal

INFOID:0000000001325735

REMOVAL

1.

Remove the following parts:

• Undercover

• Drive belts: Refer to

EM-15, "Removal and Installation"

.

• Crankshaft pulley: Refer to

PBIC1803E

PBIC0884E

Intake and exhaust

: 14.3 - 14.9 mm (0.563 - 0.587 in)

PBIC2769E