Infiniti FX35 / FX45. Manual - part 281

CO-54

< SERVICE INFORMATION >

[VK45DE]

THERMOSTAT AND WATER CONTROL VALVE

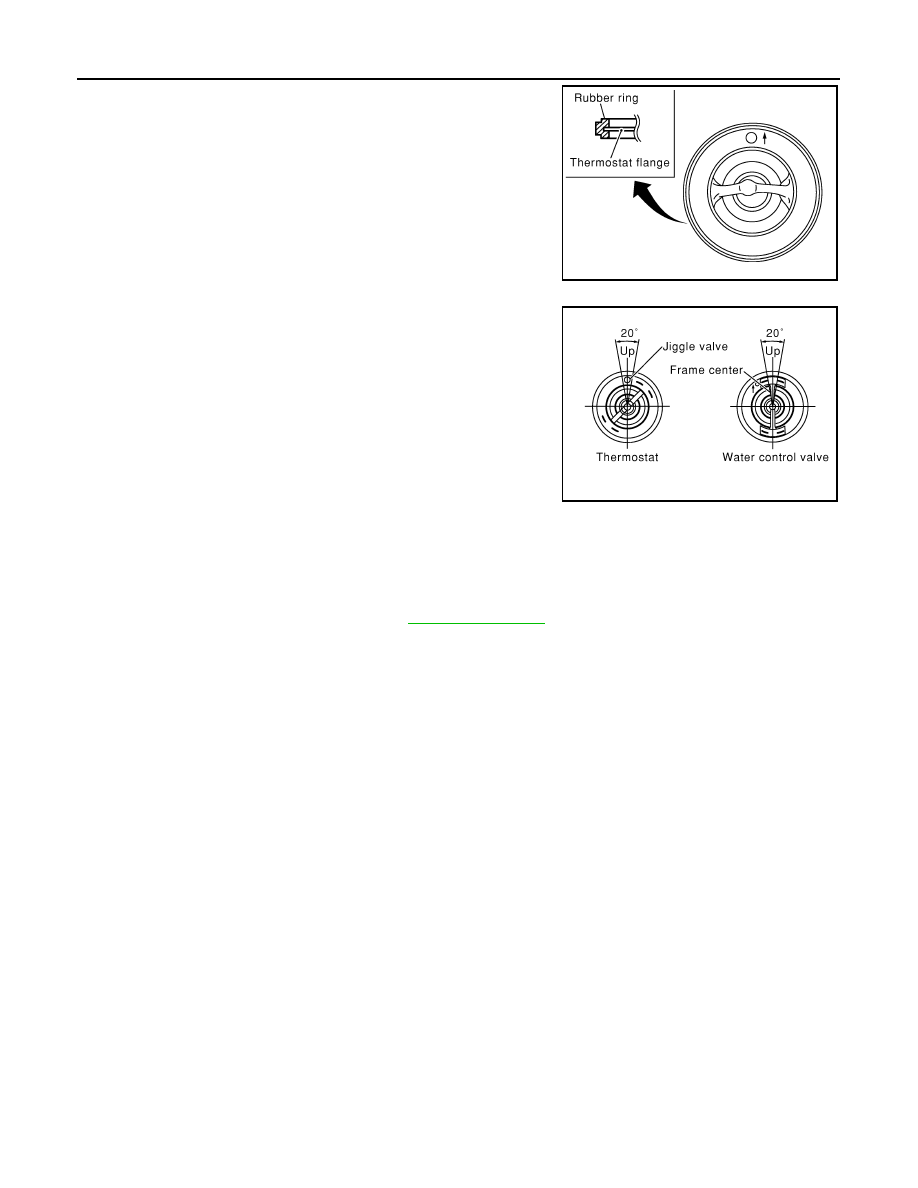

• Install thermostat and water control valve with the whole circumfer-

ence of each flange part fit securely inside rubber ring. (The exam-

ple in the figure shows thermostat.)

• Install thermostat with jiggle valve facing upwards. (The position

deviation may be within the range of

±

10 degrees)

• Install water control valve with the up-mark facing up and the frame

center part facing upwards. (The position deviation may be within

the range of

±

10 degrees)

Water Outlet Pipe and Heater Pipe

First apply a neutral detergent to O-rings, then quickly insert the insertion parts of the water outlet pipe and

heater pipe into the installation holes.

INSPECTION AFTER INSTALLATION

• Check for leaks of engine coolant using radiator cap tester adapter (commercial service tool) and radiator

cap tester (commercial service tool). Refer to

.

• Start and warm up engine. Visually check if there is no leaks of engine coolant.

PBIC0157E

PBIC0158E