Infiniti FX35 / FX45. Manual - part 186

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

BL-11

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

M

A

B

BL

N

O

P

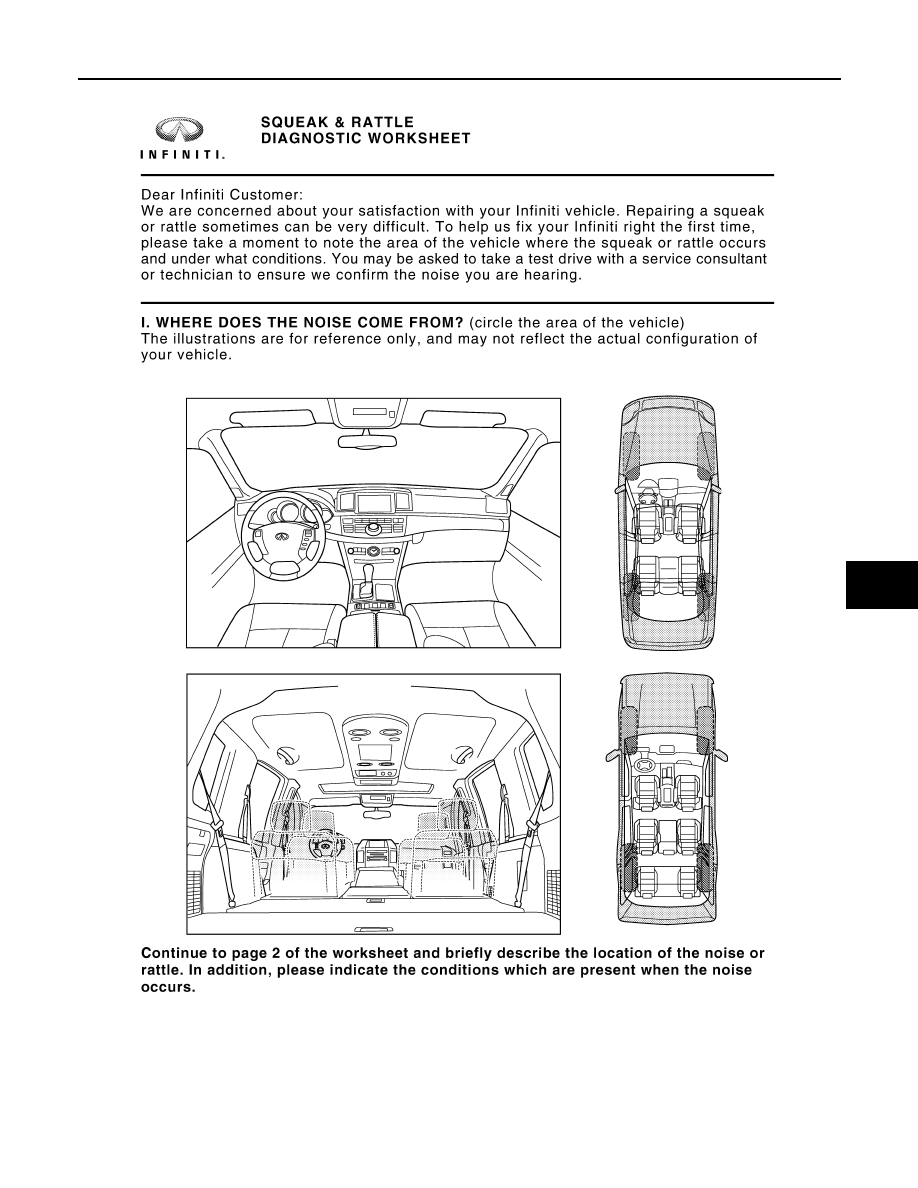

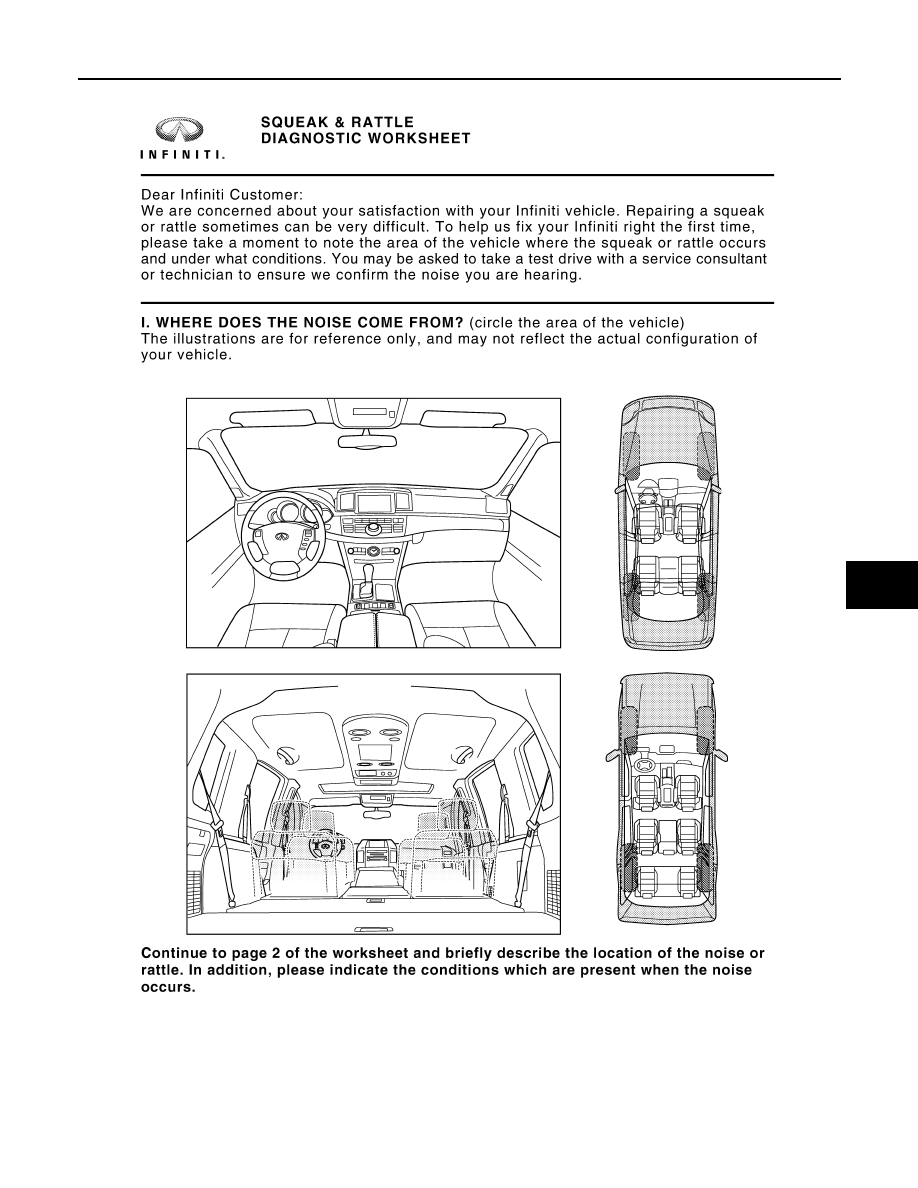

Diagnostic Worksheet

INFOID:0000000001327782

PIIB8741E

|

|

|

SQUEAK AND RATTLE TROUBLE DIAGNOSIS BL-11 < SERVICE INFORMATION > C D E F G H J K L M A B BL N O P Diagnostic Worksheet INFOID:0000000001327782 PIIB8741E |