Infiniti FX35, FX50 (S51). Manual - part 943

EM-72

< REMOVAL AND INSTALLATION >

[VQ35HR]

CAMSHAFT

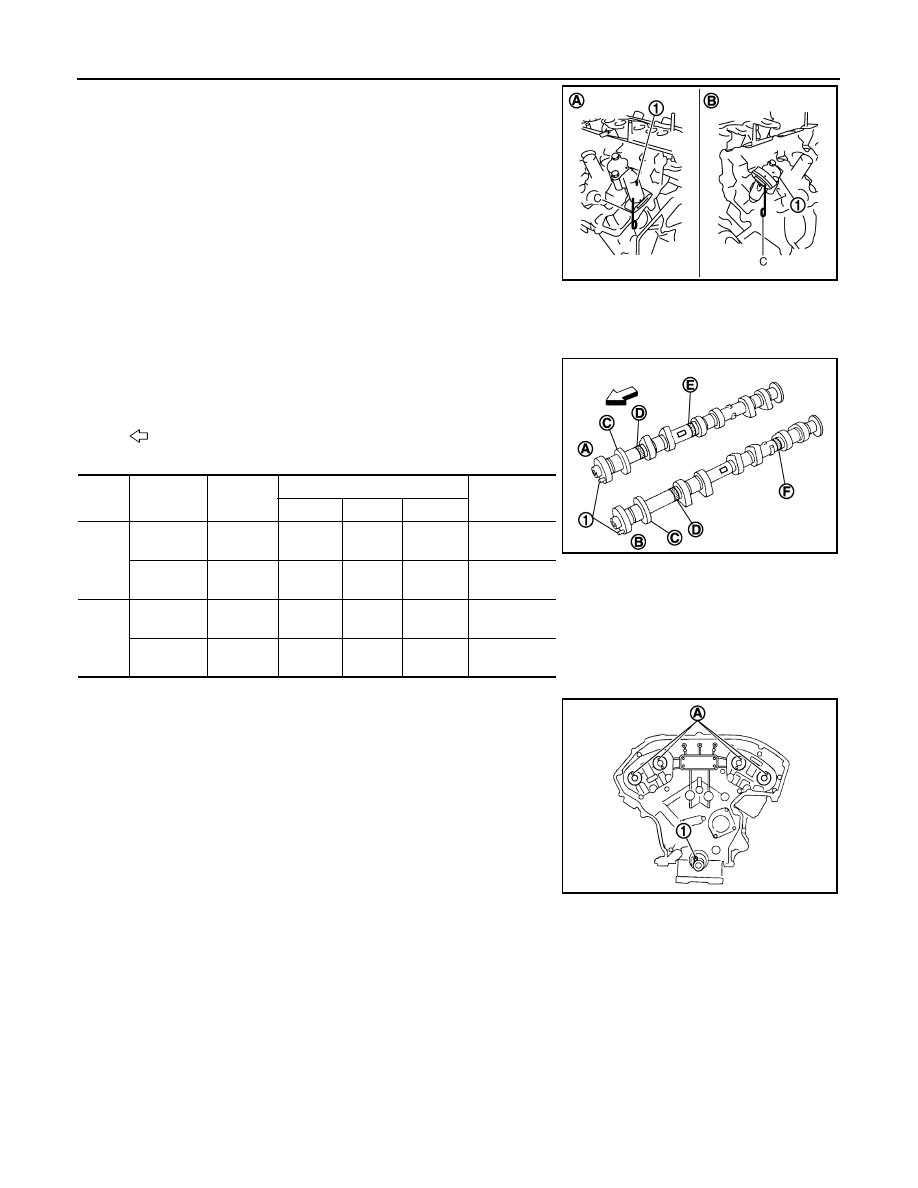

• Install timing chain tensioners (1) with its stopper pin (C)

attached.

2.

Install valve lifter.

• Install it in the original position.

3.

Install camshafts.

• Follow your identification marks made during removal, or fol-

low the identification marks that are present on new camshafts

for proper placement and direction.

• Install camshaft so that dowel pin (A) on front end face are

positioned as shown in the figure. (No. 1 cylinder TDC on its

compression stroke)

NOTE:

Though camshaft does not stop at the portion as shown in the

figure, for the placement of cam nose, it is generally accepted

camshaft is placed for the same direction of the figure.

Bank 1 side (A)

: Sliding part facing downward

Bank 2 side (B)

: Sliding part facing upward

JPBIA0121ZZ

: Engine front

Bank

INT/EXH

Dowel pin

(1)

Paint marks

Identification

mark (C)

M1 (E)

M2 (F)

M3 (D)

1

EXH (B)

Yes

No

Green

Light

blue

1F

INT (A)

Yes

Green

No

Light

blue

1E

2

INT (A)

Yes

Green

No

Light

blue

1G

EXH (B)

Yes

No

Green

Light

blue

1H

JPBIA1191ZZ

1

: Crankshaft key

JPBIA0094ZZ