Infiniti FX35, FX50 (S51). Manual - part 836

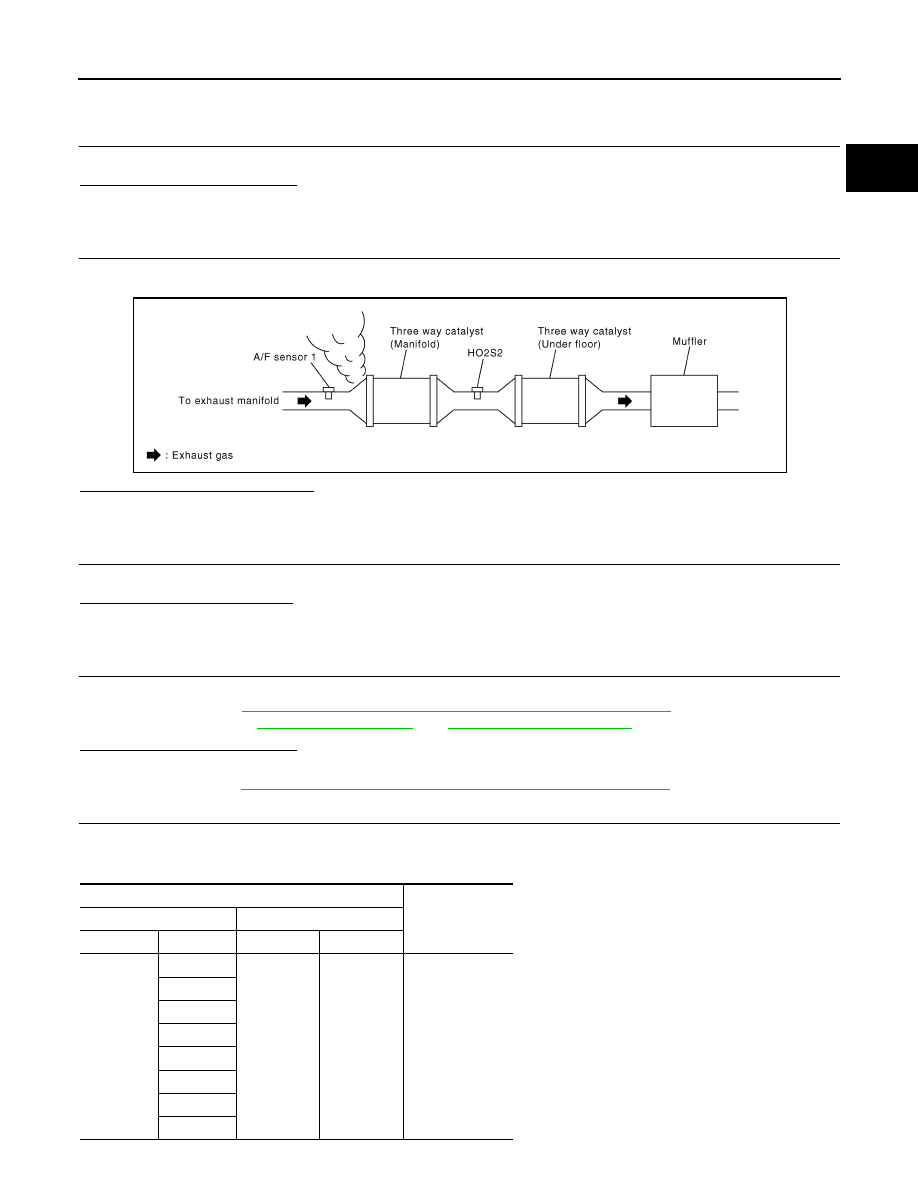

P0420, P0430 THREE WAY CATALYST FUNCTION

EC-885

< DTC/CIRCUIT DIAGNOSIS >

[VK50VE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Diagnosis Procedure

INFOID:0000000005237361

1.

CHECK EXHAUST SYSTEM

Visually check exhaust tubes and muffler for dents.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace malfunctioning part.

2.

CHECK EXHAUST GAS LEAKAGE

1.

Start engine and run it at idle.

2.

Listen for an exhaust gas leakage before the three way catalyst (manifold).

Is exhaust gas leakage detected?

YES

>> Repair or replace malfunctioning part.

NO

>> GO TO 3.

3.

CHECK INTAKE AIR LEAKAGE

Listen for an intake air leakage after the mass air flow sensor.

Is intake air leakage detected?

YES

>> Repair or replace malfunctioning part.

NO

>> GO TO 4.

4.

CHECK IDLE SPEED AND IGNITION TIMING

Check idle speed and ignition timing.

For procedure, refer to

EC-576, "BASIC INSPECTION : Special Repair Requirement"

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Follow the

EC-576, "BASIC INSPECTION : Special Repair Requirement"

.

5.

CHECK FUEL INJECTORS

1.

Stop engine and then turn ignition switch ON.

2.

Check the voltage between ECM harness connector terminals as per the following.

PBIB1216E

ECM

Voltage

+

–

Connector

Terminal

Connector

Terminal

F110

17

M160

128

Battery voltage

21

25

29

33

37

41

45