Content .. 1080 1081 1082 1083 ..

Infiniti FX35, FX50 (S51). Manual - part 1082

FAX-26

< REMOVAL AND INSTALLATION >

[AWD]

FRONT DRIVE SHAFT

FRONT DRIVE SHAFT

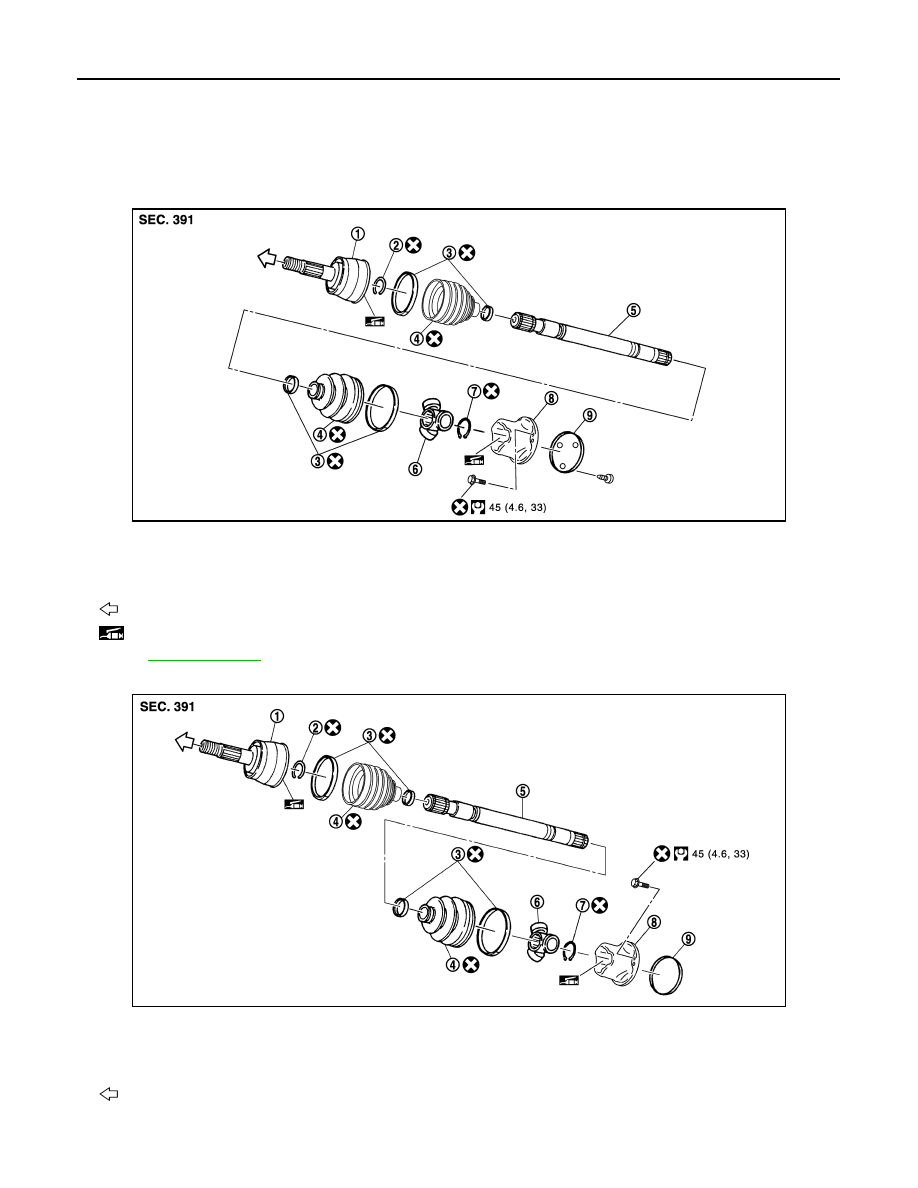

Exploded View

INFOID:0000000005248994

LEFT SIDE

VQ35HR

VK50VE

JPDIF0168GB

1.

Joint sub-assembly

2.

Circular clip

3.

Boot band

4.

Boot

5.

Shaft

6.

Spider assembly

7.

Snap ring

8.

Housing

9.

Plug

: Wheel side

: NISSAN genuine grease or an equivalent.

Refer to

for symbols not described on the above.

JPDIF0191GB

1.

Joint sub-assembly

2.

Circular clip

3.

Boot band

4.

Boot

5.

Shaft

6.

Spider assembly

7.

Snap ring

8.

Housing

9.

Plug

: Wheel side