Infiniti EX35. Manual - part 718

CAMSHAFT

EM-71

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

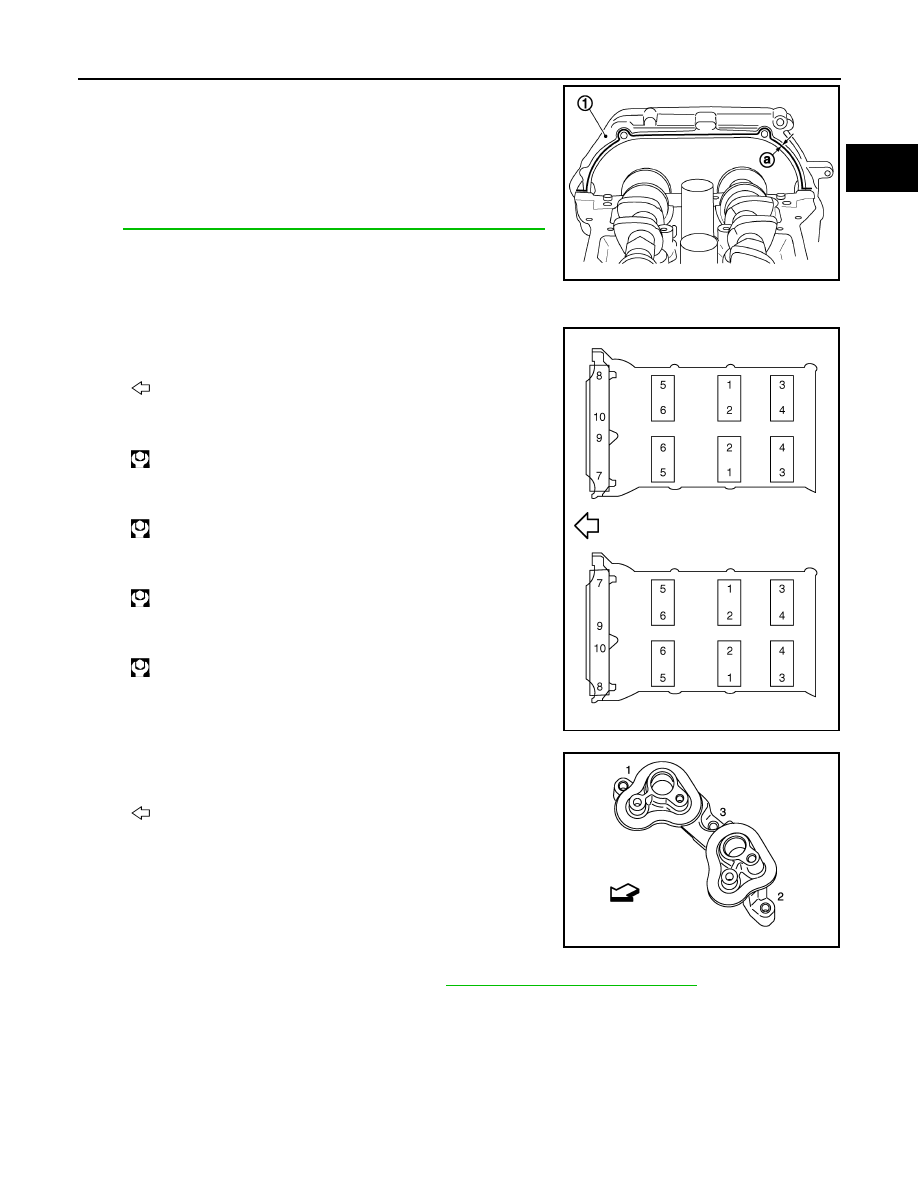

• Apply liquid gasket to camshaft bracket (No. 1) contact surface

on the rear timing chain case backside as shown on both bank

1 and bank 2.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-15, "Recommended Chemical Products and Sealants"

.

CAUTION:

For camshaft bracket (No. 1) near installation position,

and install it without disturbing the liquid gasket applied

to the surfaces.

5.

Tighten camshaft bracket bolts in the following steps, in numeri-

cal order as shown in the figure.

a.

Tighten No. 7 to 10 in numerical order as shown.

b.

Tighten No. 1 to 6 in numerical order as shown.

c.

Tighten No. 1 to 10 in numerical order as shown.

d.

Tighten No. 1 to 10 in numerical order as shown.

6.

Tighten camshaft sensor bracket bolts in numerical order as

shown in the figure.

NOTE:

The order of tightening bolts is the same for bank 1 and bank 2.

7.

Inspect and adjust the valve clearance. Refer to

EM-18, "Inspection and Adjustment"

.

8.

Install in the reverse order of removal after this step.

Inspection

INFOID:0000000003139121

INSPECTION AFTER REMOVAL

Camshaft Runout

1

: Rear timing chain case

a

:

φ

3.9 mm (0.154 in)

JPBIA0881ZZ

: Engine front

: 1.96 N·m (0.20 kg-m, 1 ft-lb)

: 1.96 N·m (0.20 kg-m, 1 ft-lb)

: 5.88 N·m (0.60 kg-m, 4 ft-lb)

: 10.4 N·m (1.1 kg-m, 8 ft-lb)

JPBIA0257ZZ

: Engine front

JPBIA1960ZZ