Hyundai: Engine D4FA. Manual - part 49

DIESEL CONTROL SYSTEM

FLA -67

[IATS (INSTALLED INTO MAFS)]

Temperature℃(℉)

Resistance(kΩ )

-20

12.66 ~ 15.12

0

5.2 ~ 5.9

20

2.29 ~ 2.55

80

0.31 ~ 0.37

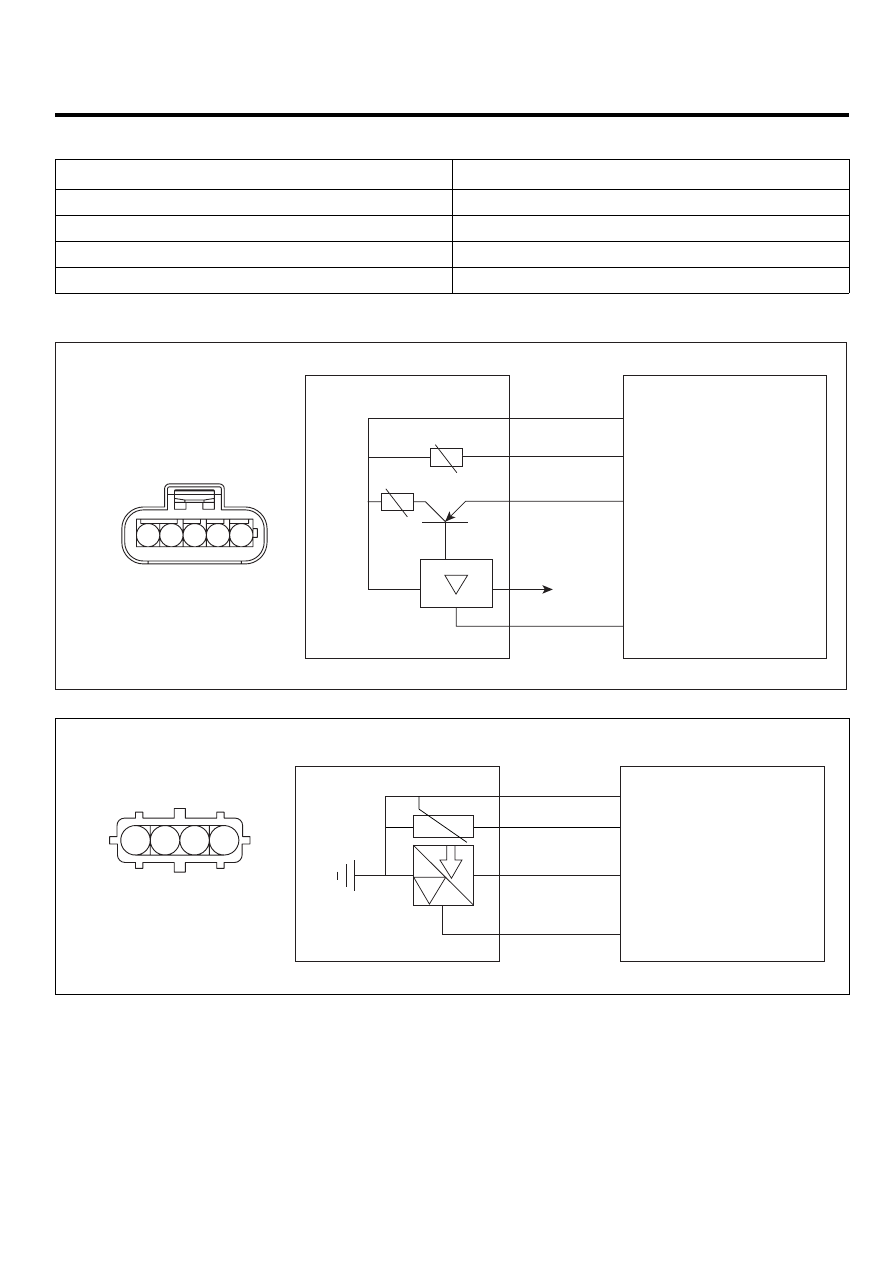

CIRCUIT DIAGRAM

C103

MAFS & IATS 1

ECM

MAFS Ground

IATS 2 Signal

MAFS Signal

MAFS current pumping

2

3

C101-1 (44)

C101-2 (89)

C101-1 (42)

C101-1 (37)

Battery (+)

5

1

4

1

2

3

4

5

EGNG112A

3

4

C101-1(23)

C101-1(53)

C101-1(13)

C101-1(40)

2

1

GROUND

5V supply

IATS1 Signal

BPS signal

BPS & IATS 2

P

C130

Harness side

1

2

3

4

EGNG114A