Hummer H1 (1992-1998). Manual - part 42

2 - 3 5 . 3 . (6.2L or 6.5L) FUEL INJECTION PUMPS (DB2829-4523, DB2829-4879, or

DB2831-5149) CALIBRATION USING FUEL INJECTION PUMP TEST STA N D

(FTIS) MODEL A8022 (Cont’d)

2-140.16 Change 1

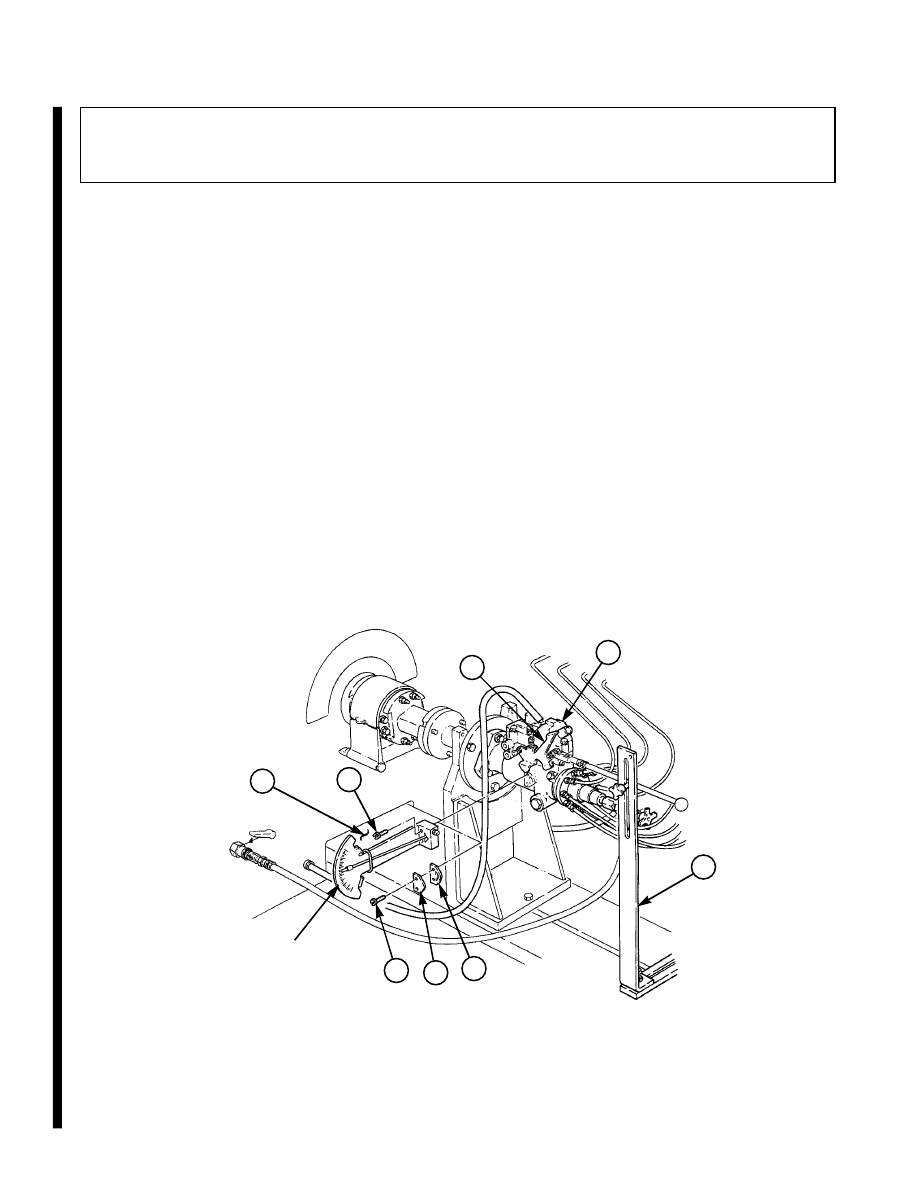

16.

Position throttle arm positioner assembly (3) on bedplate (7) and throttle lever (1).

NOT E

When installing advance indicator, ensure the flat on pointer end

engages into the cam ring slot on fuel injection pump.

17.

Remove two screws (6), timing cover (5), and gasket (4) from fuel injection pump (2) and install

advance indicator with two screws (6).

18.

Remove screw plug from advance indicator block and install quick-connect on advance indicator

block (8).

19.

Attach one end of rubber hose assembly to quick-connect and the other hose assembly end to

auxiliary pressure quick-connect plug on front panel of test stand.

20.

Connect positive red test lead to DC power supply socket marked (+) on test stand, and attach the

alligator clip end of red test lead to the electric shutoff solenoid terminal (9) on fuel injection

pump (2).

21.

Connect black lead to DC black socket marked “P” on test stand and connect alligator clip end of

black lead to ground terminal (10) on fuel injection pump (2).

22.

After installation and hookup of the fuel injection pump has been completed, inspect pump, all

hoses, and related hardware connections before beginning pump calibration. Review operation test

procedures for the FTIS prior to calibrating the fuel injection pump.

2

3

4

5

6

1

7

6

ADVANCE

INDICATOR