Great Wall Hover. Manual - part 75

Brake-21

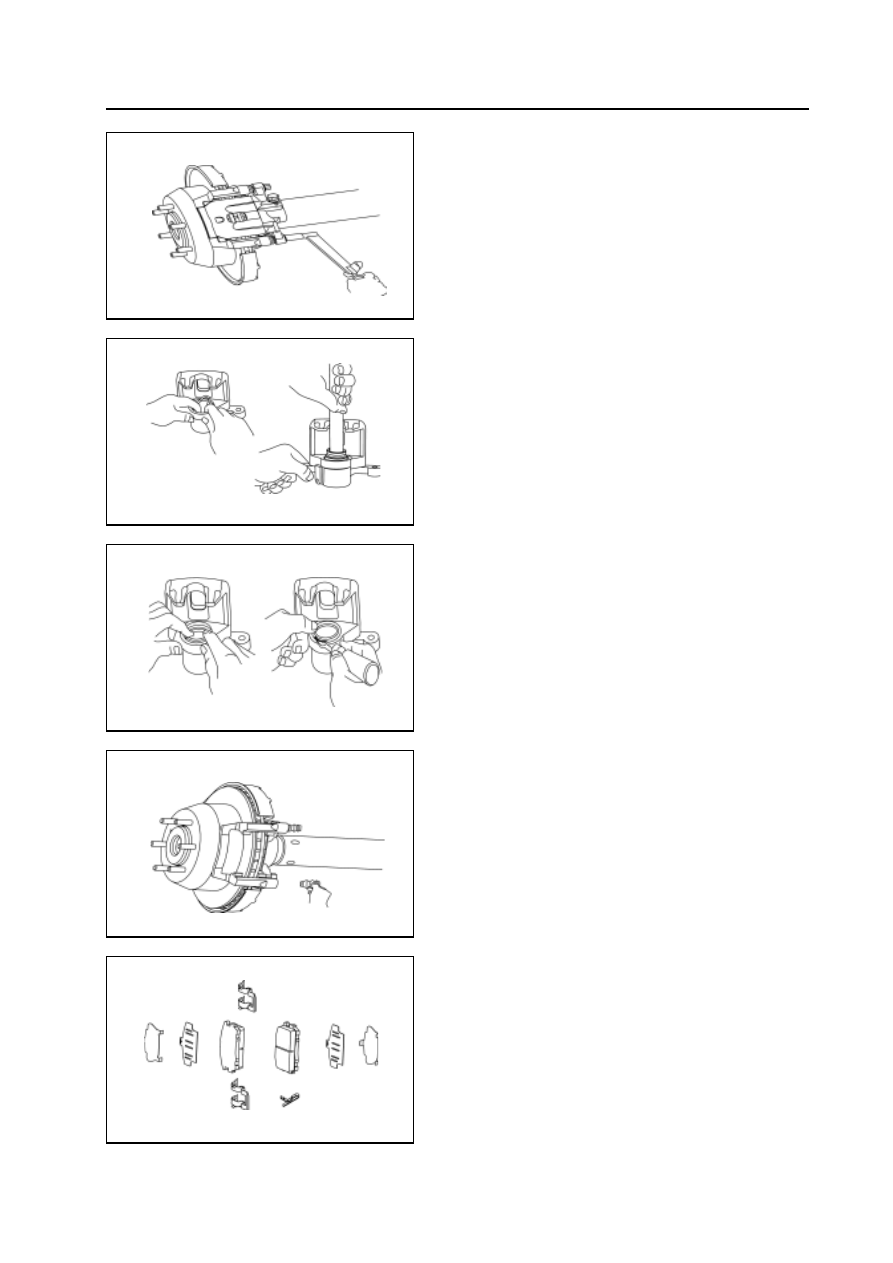

Assembly of pump

1. During the assembly, coat the guide pin with the proper vacuum

sili con based grease; coat the operating surface of piston and

square gasket with proper rubber lubricant.

2. Install the piston gasket and piston in the tong

3. Install the cylinder hole dustproof cover and wire clip in the

tong.

4. Install the rubber pin cover on the tong bracket.

Installation of brake caliper

1. Install the brake block