Great Wall Hover. Manual - part 65

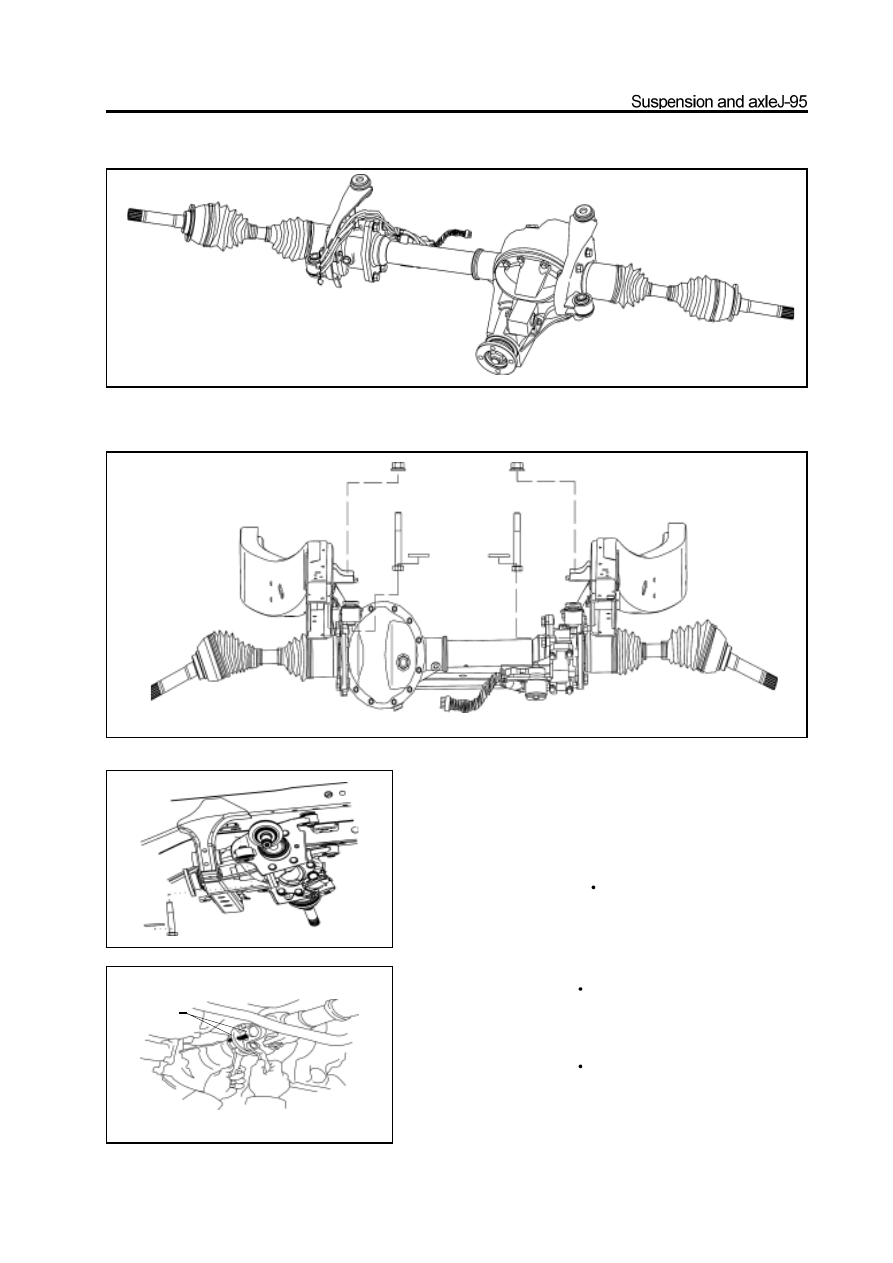

Installation of front reducer assembly

1. Install the front drive shaft assembly on the reducer assembly (Refer to “Assembly of Front

Drive Shaft”)

assembly mark

2. Use the jack to support the front drive axle, insert the

hanger plank bolt with washer and tighten it to the speci-

fied torque.

Remarks: Do not insert the previous two bolts in reverse direction.

Specified torque : 200-220N

m

3. Use the bolt to connect the front drive axle flange to

the drive shaft according to the mark made before

disassembly, and tightens it to the specified torque.

Specified torque : 73-83N

m

4. Install the beam under the front drive axle; tighten

the connecting bolt of the beam to the specified torque.

Specified torque : 73-83N

m

5. Connect the power sire connector of the electric

clutch to the power output wire of the car.