Great Wall Hover. Manual - part 2

Front shaft/axle

CC6460K wagon has the two-cross arm, independent suspension, breakaway front axle.

CC6460KY wagon has the two-cross arm, independent suspension, breakaway steering drive axle , hyperbolic gear single-stage main

reducer, plain bevel gear differential mechanism, universal drive semiaxle, Birfield ball-joint, main reduction ratio i

0

=4.55, Max. input

torque is 900N

m.

Rear axle

Non-breakaway drive axle, integral stamping-welded axle housing, hyperbolic gear single-stage main reducer, plain bevel gear differential

mechanism, semi-floating semiaxle, main reduction ratio i

0

=4.55, Max. input torque is 900N

m.

Wheel and tyre

The type, specification and main parameter of wheel and tyre see Table 4.

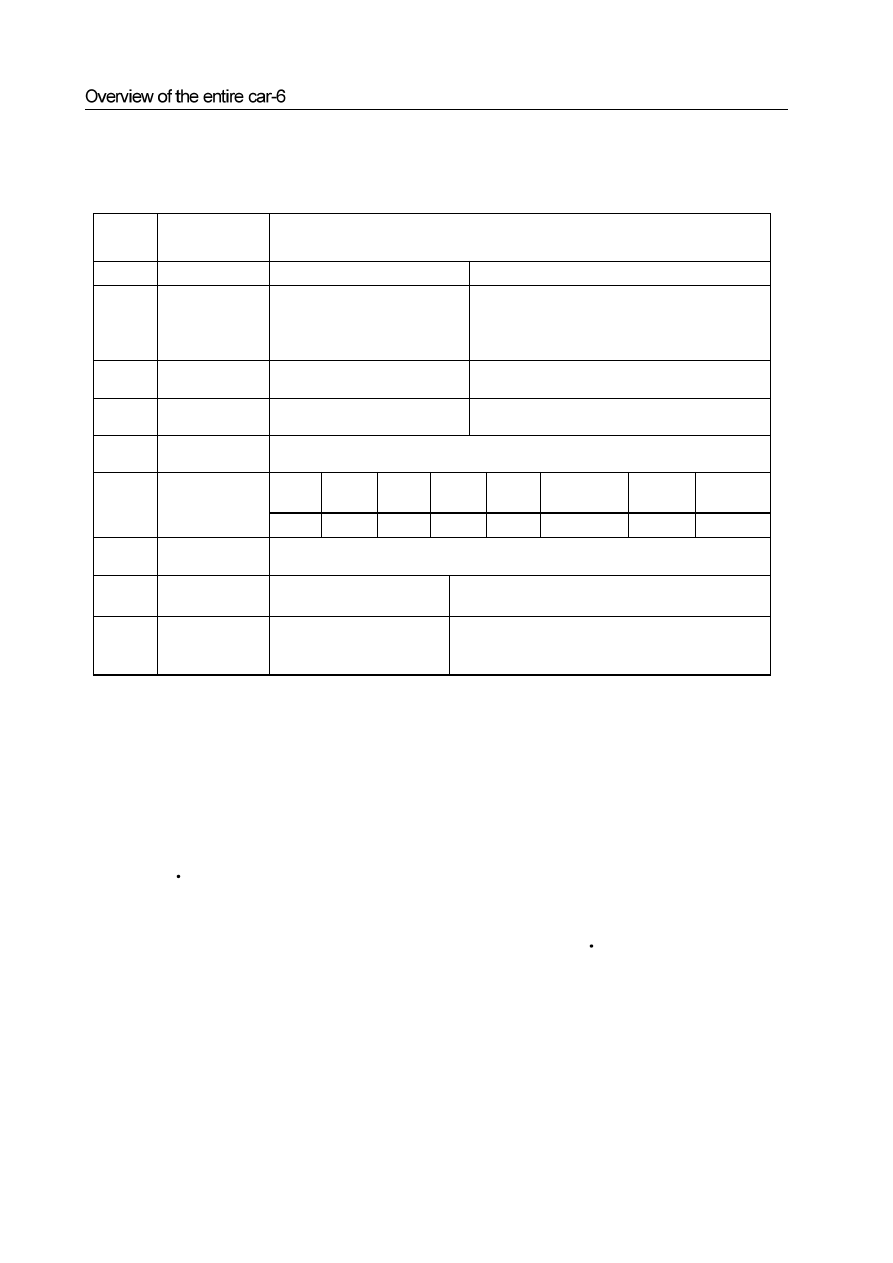

Table 4 Type, specification and main parameter of wheel and tyre

Transmission

For the structure and main technical parameter of transmission see Table 3.

Table 3 Structure and main technical parameter

Serial

No.

Item Specification

and

parameter

1 Model

SC5M2D-C

SC5M4D-C

2 style

manual mechanical step

transmission of full synch, 5

forward steps, 1 reverse step, direct

manipulation

manual mechanical step transmission with torque

divider of full synch, 5 forward steps, 1 reverse step,

direct manipulation

3

Center

distance(mm)

72

72(transmission), 222.25 (torque divider)

4

Max. input torque

(N. m)

196

196

5

Max. input torque

(r/min)

5500

Step

I

Step

II

Step

III

Step

IV

Step

V

Step

R(Reverse)

Step

H(high)

Step

L(low)

6 Speed

ratio

7

Gear pair of

speedometer

8:25

8

Total net

weight(kg)

38 68(include

torque

divider)

9

Outline

dimension: L×W

×H

1070mm×466mm×

399mm( not include height of

steering level)

1070mm×460mm×380mm( not include height of

steering level)

Drive shaft

The structure of rear drive shaft assembly of CC6460K wagon is the three cross-axle universal joints, two drive shafts with extens

intermediate support free-maintenance segmental structure. The front and rear drive shaft assembly of CC6460KY wagon has the

universal joints, one drive shaft with extension spline, free-maintenance integral structure respectively.