Great Wall Florid. Manual - part 28

GWFLORID Maintenance Manual

110

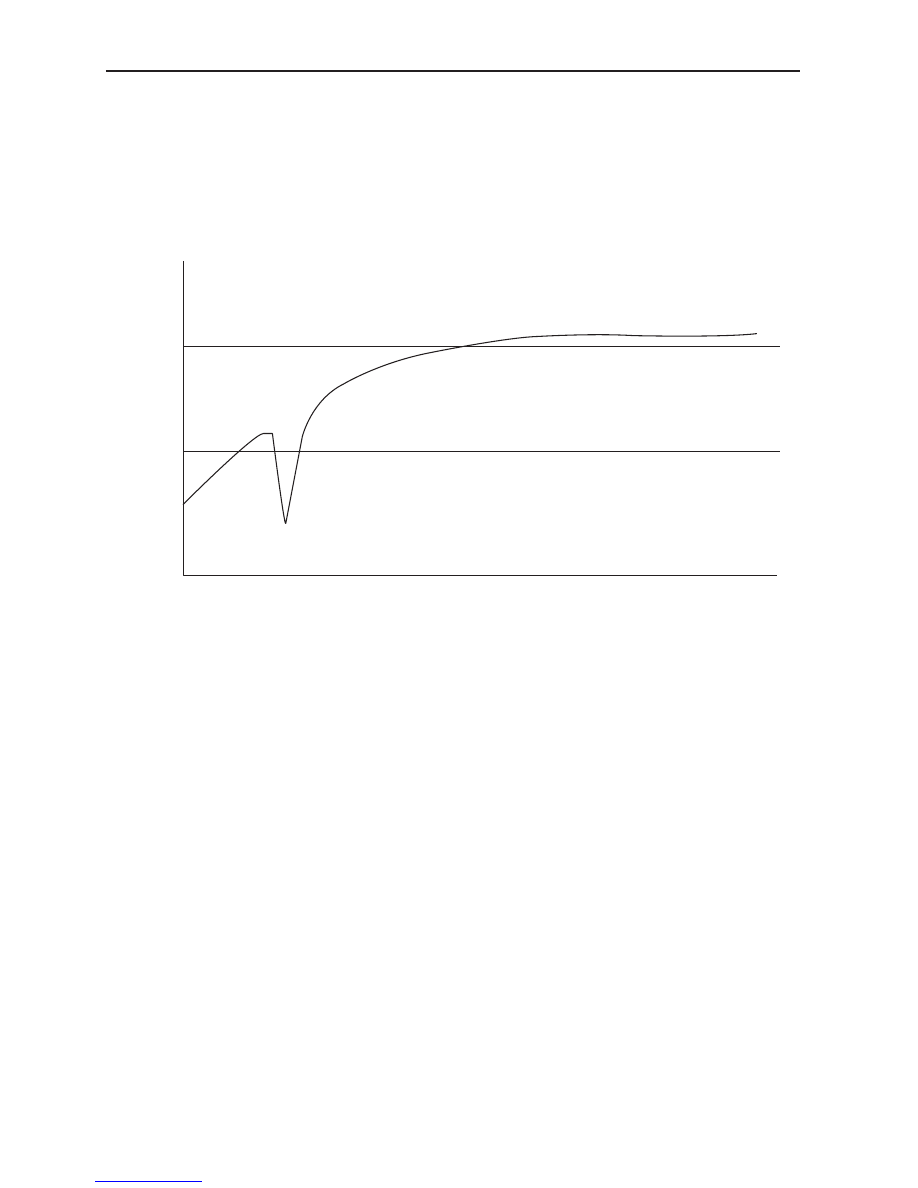

The X431 scanner possesses a waveform function. Wheel speed signal error (wheel speed sensor failure)

only appears when intermittent problems occure, such as high speed. When in use, some signal errors may

occasionally appear. Continue observing the waveform to make sure there is nothing abnormal.When driving

the vehicle on a flat and straight road, all four wheels' speed sensor waveform are extremely similar. One can

compare the two front wheels' with the two rear wheels' signal wave at the same time.

Mechanical causes:

Signal gear distortion, loosened hub bearings, smudges on the sensor surface, etc, all may lead to wheel speed

signal intermittency and inaccuracy. Failure examples:

As shown above, once the intermittent failures with the wheel's speed sensor signal are detected, the ABS

control unit records the sensor problems and lights up the warning lamp.

4. Wheel speed sensor velocity failure (ECU detects an excessive difference between the two wheels'

speed sensor signals).

Possible causes are the gear's wheel speed sensor gap is overly large, or the wheel speed sensor signal is

experiencing interference. For this, first determine which sensor is emitting the signal, and then use failure

three's maintenance methods.

Areas of Importance

1. Sometimes, in order to determine whether there is a common brake system problem or an ABS

problem, the ABS must be terminated by pulling out its ABSECU connector or fuse. At this time the

ABS/EBD loses function as well. On muddy, icy, or snowy roads, the vehicle may fishtail or slide, in

which cases one must be extremely careful to avoid hard braking.

2. The ABS malfunction rate is extremely low, when the brake system shows any problem (before the

warning lamp goes on), first eliminate the normal brake system problems, then consider the ABS mal-

functions.

3. When raining or on gravel, this adjusting process is longer than the standard process, because this

kind of road's unstable adhesion coefficient will lead to a difference between the sliding measurement

and calculation procedures, thus it is necessary to remind drivers to be especially careful when driving

under the circumstances mentioned above.

4. ABSECU Areas of Importance:

(a) The ABSECU is easily damaged from impacts or collisions, thus pay attention to ensure the ECU avoids

such incidents.

(b) High temperature environments can also easily damage the ECU, so when the vehicle undergoes hot paint

work, make sure to first take the ECU out of the vehicle.

(c) When the power switch is ON, do not disassemble the system's electrical elements and wire harness plugs,

in order to avoid damage to the ECU. If removal or installation must be carried out, be sure to disconnect

the ignition switch firstly. When welding components or circuits to the system, the wire harness plug

V( Km/h)

60

30

Signal interrupt

t