Главная Geely Common Malfunction Diagnosis Flow of Geely Automobile - 2008 year

|

|

|

содержание .. 30 31 32 33 34 ..

Geely Diagnosis Flow. Manual part - 33

129 No.068 Diagnosis and solution of common malfunctions of JL376/378QE engine’s electric control system

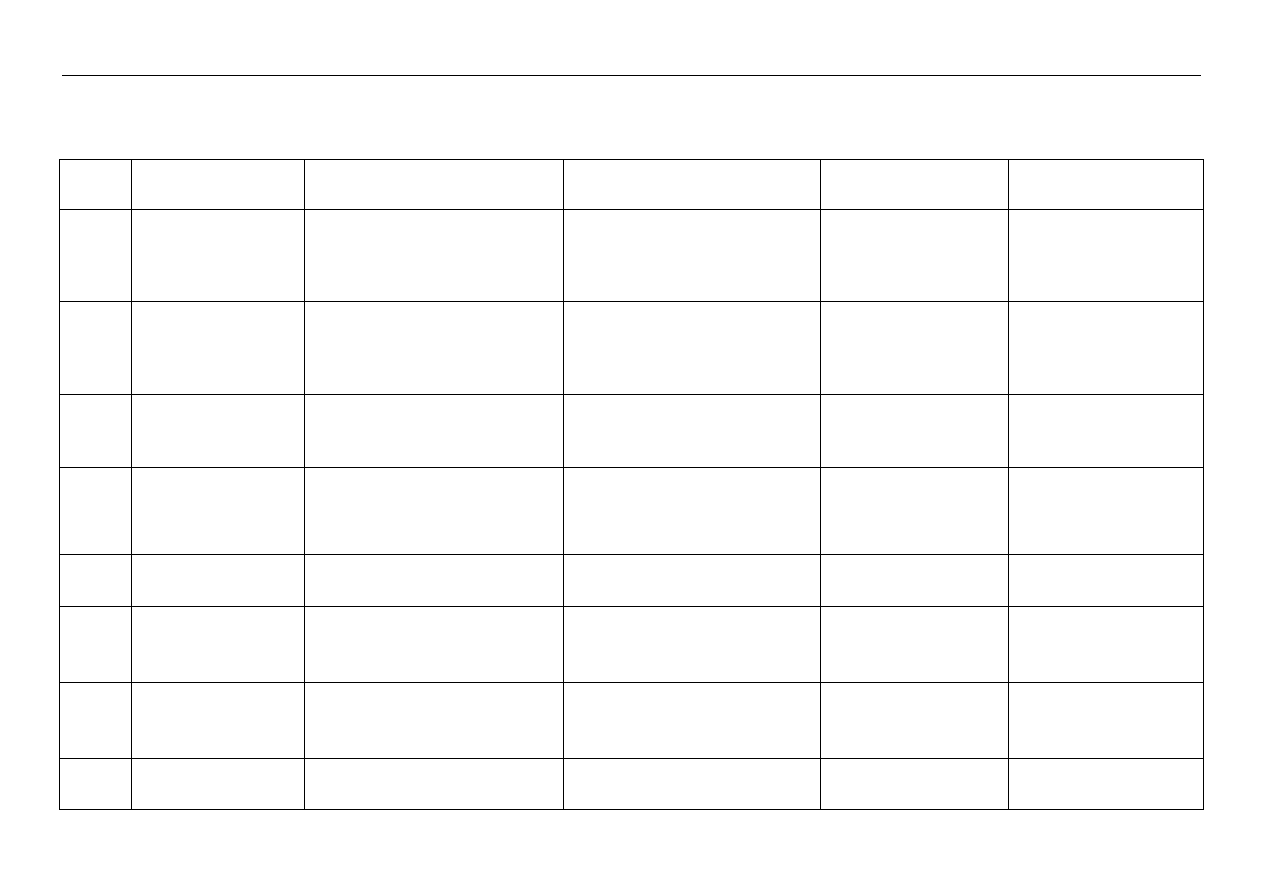

Serial No. Malfunction Display by diagnosis instrument Analytic procedure Causes Measures 1. After startup, flame out λ integral quantity exceeding lower limit Obviously oil injection not normal; check ECU malfunction; malfunction Replace ECU 2. Unable to startup (started Diagnosis instrument ON, but unable to Key placed to the second position, and Fuse broken, causing ECU27 Replace fuse 3. Unable to startup Diagnosis instrument without display Electric injection system without power Fuse broken, causing ECU18 Replace fuse 4. Startup with burning, and Two malfunctions: Throttle valve position sensor shorted to earth Pressure sensor shorted to earth Measure connections between ECUl2 pin not ON with Replace harness 5. Instable idling speed, but / / /

/ 6. Instable idling speed, / Not malfunction

Self-learning of stepper motor Flame out, wait for 10s, and 7. Unable to start Without malfunction. When the motor is Check hall element is working normally Hall element 48 pin broken Improve harness quality 8. Unable to start Without malfunction. Oil pump relay is with closing sound, but Check fuse or lines from oil

|