содержание .. 20 21 22 23 24 25 26 ..

Geely Diagnosis Flow. Manual part - 25

97

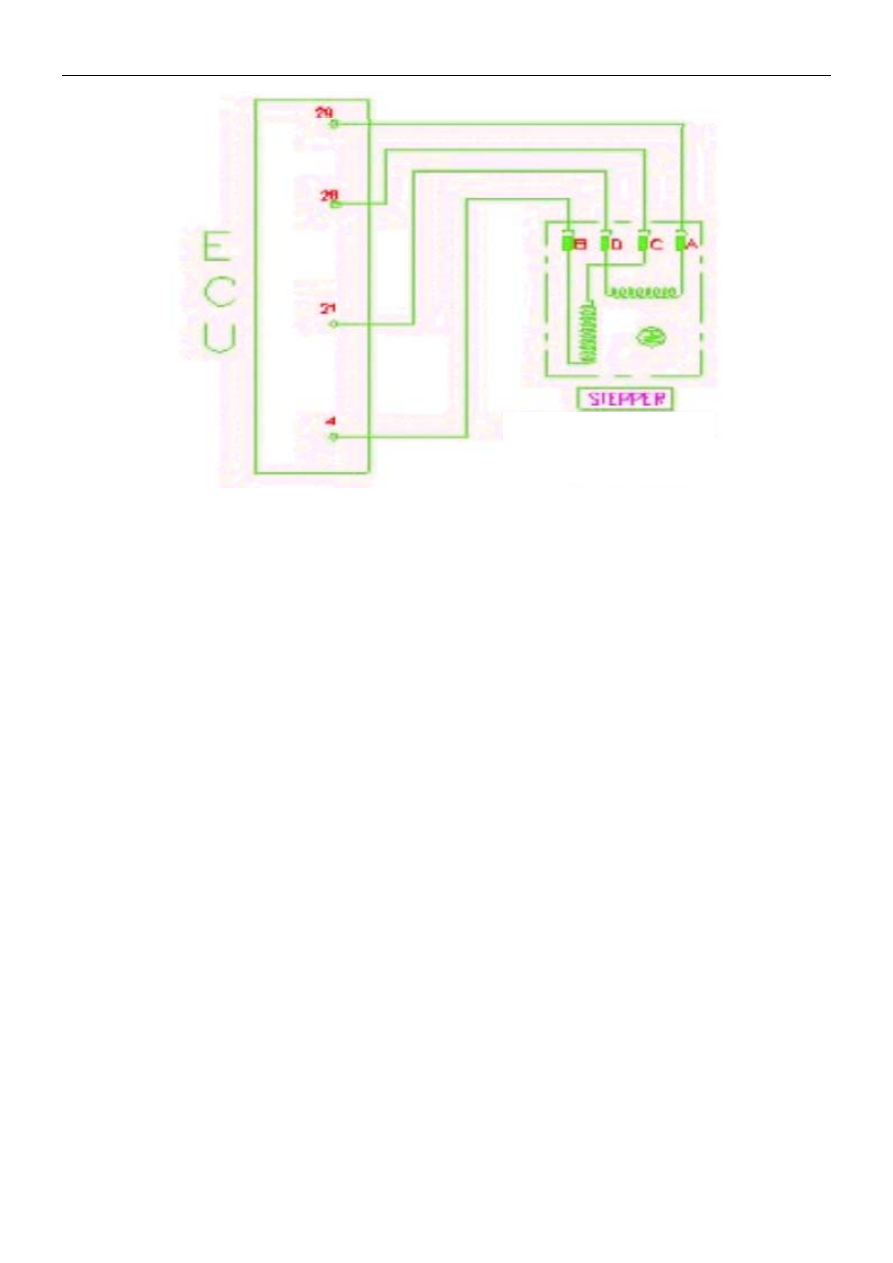

Idle speed actuator step motor

|

|

|

содержание .. 20 21 22 23 24 25 26 ..

Geely Diagnosis Flow. Manual part - 25

97

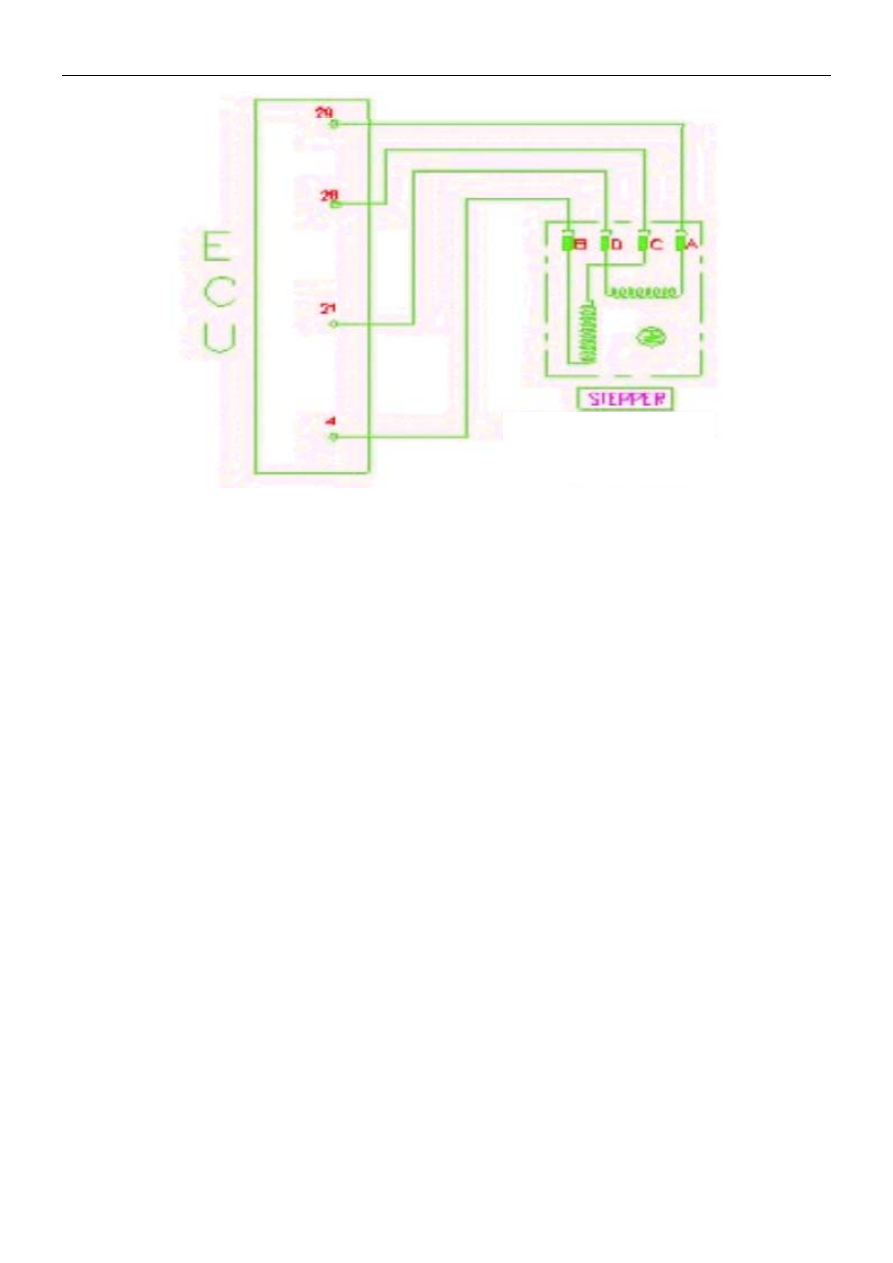

Idle speed actuator step motor

|