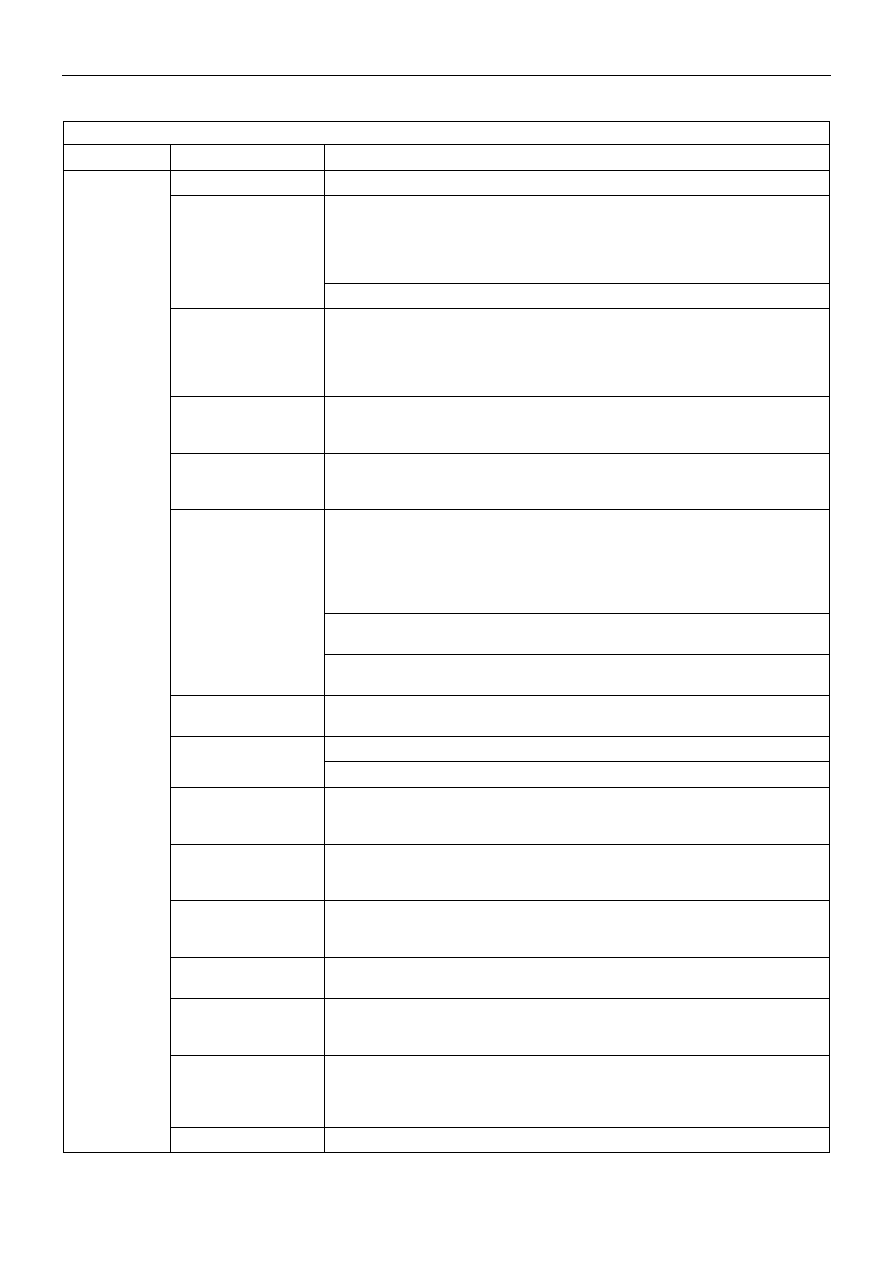

Geely Diagnosis Flow. Manual part - 12

45

No. 027 Engine fails to start

Malfunction Cause

Solution

No fuel

Check fuel gauge and fuel level

Check battery voltage, whether it is normal, which shall above 11.5V. Charge or

replace battery when the value is too low. Check or replace circuit, if battery fails to

be charged as normal (check whether there is short circuit in inner/outer circuit,

which results current leaking). Check battery circuit and all connections, whether

they are well conducted.

Low battery voltage

Check starter, whether it operates normally. Maintain or replace it when necessary.

Starter malfunction

Check starter, whether it operates normally. Check starter circuit, solenoid switch,

carbon brush, coil and rotor, whether there is short or open circuit, as well as poor

conduction. Check one-way clutch whether it is slipping, as well as one-way clutch

and fly wheel tooth, whether they are damaged. Maintain or replace them when

necessary.

Ignition switch open

circuit and wire

malfunction

Check circuit, fuse, ignition switch by multimeter, set to resistance range, whether

they are open circuit. To inspection the malfunction.

Electric control system

malfunction

Connect Geely special No. to check whether there is malfunction No.. And inspect

again if it shows malfunction No.. Then check relevant component and circuit

according to the indication of malfunction No..

Check high voltage spark, if it operates normally, then check engine speed sensor,

ignition coil, ECU and relating circuit. Maintain or replace them when necessary.

(Connect two pins of primary winding respectively to multimeter, and the

resistance shall be 0.4~0.6Ω at 20 . In same condition, the resistance of

℃

secondary winding shall be 11~15kΩ. Connect pin 2 and pin 3 of sensor to

multimeter pen respectively, and at 20 the rated resistance shall be 860Ω±10%)

℃

Check ignition timing, if it is improper, then check flywheel signal plate, whether it is

loose and malposition. Maintain or replace it when necessary.

Improper ignition

timing or weak spark

voltage

Check high voltage spark energy, if it is weak, then check ignition coil, high voltage

resistance. Replace it when necessary.

Spark plug malfunction

Check spark plug electrode clearance and carbon deposit condition. Adjust or

replace it when abnormal.

Check timing belt, whether there is damage. Replace it when necessary.

Incorrect valve timing

Check timing belt, whether there is damage. Replace it when necessary.

Air filter blocked or

intake system leaking

Check air filter, whether it is blocked. Clean or replace it when necessary. Check

intake system, particularly intake manifold, injector, vacuum pipe and connector,

whether they are leaking. Exclude the malfunction when necessary.

Fuel system

malfunction

Fuel pressure shall above 260kPa when idling. Otherwise, the fuel pressure is low,

and shall check fuel pump, fuel pressure controller and fuel pipe, whether there is

malfunction.

Engine signal plate

loose or moved

Check engine signal plate, whether is it loose or moved. When necessary, shall

position it (20 teeth after point T for 4-cylinder, 16 teeth after point T for 3-cylinder)

first, then weld or replace engine signal plate.

Exhaust system

blocked

Check or replace exhaust system blocking position

Low cylinder pressure

Measure cylinder pressure. Fill a few oil into cylinder to determine whether the

cylinder or piston ring worn out, as well as valve sealing leaking. Adjust valve

clearance or disassemble engine when cylinder pressure is too low.

Injector malfunction

Check both ends of connector of each injector by oscillograph or multimeter,

whether there is pulse signal. If not, shall check parts of controlling circuit or ECU.

Otherwise, remove injector and check fuel injection quantity and atomization,

whether it is normal. Clean or replace it when necessary.

Engine fails to

start

ECU malfunction

ECU controller fails to input or output signal normally, replace it.