Ford Fiesta (1989-1995). Instruction - part 58

8 Refitting is a reversal of the removal

procedure.

Front direction indicator side

repeater

9 Remove the appropriate front wheel arch

liner as described in Chapter 11.

10 Remove the appropriate sill scuff plate as

described in Chapter 11, and release the clip

securing the insulation to the panel forward of

the lower A-pillar.

11 Disconnect the supply lead connector and

the earth lead, then release their grommet

from its panel location.

12 From outside the vehicle, twist the light

assembly to release it, then withdraw it and its

leads.

13 Refitting is a reversal of the removal

procedure, ensuring that the grommet is

seated correctly in its panel location.

Rear light cluster

14 Disconnect the multi-plug from the

bulbholder, then press the retaining lugs on

the bulbholder together and remove it (see

illustration).

15 Unscrew the four nuts securing the light

unit, then remove the unit and its seal.

16 Refitting is a reversal of the removal

procedure. Tighten the light unit securing nuts

to their specified torque.

Number plate light

17 Insert a thin flat-bladed screwdriver

between the light assembly and the bumper,

and carefully prise the light out. Use a rag, or

a piece of card, between the screwdriver and

the bumper, to prevent damage to the

bumper.

18 Detach the connections on the underside

of the light assembly.

19 Refitting is a reversal of the removal

procedure.

Auxiliary lights

S models

20 Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

21 Disconnect the light wiring multi-plug then

unscrew its retaining nut, withdraw the bolt

and remove the light unit (see illustration).

22 Refitting is a reversal of the removal

procedure, tightening the retaining nut to the

specified torque. On completion, check the

auxiliary light beam alignment as described in

Section 8.

XR2i models

23 Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

24 Undo the four Torx retaining screws

securing the relevant dual light assembly to its

bumper location. Note that the retaining and

adjusting screws are captive within the light

assembly - they cannot be removed from

the assembly (see illustration).

25 Withdraw the light assembly from its

location, then remove the caps protecting the

bulbs and disconnect the wiring.

26 If required, the lights may be removed

individually from their housing at this stage.

Each light is secured to its housing unit by a

combination of two types of clips - foglight

retention differs from driving light retention.

27 The adjusting/retaining clips are removed

by undoing the adjustment screws on the

front of the housing unit, then turning the clips

using pliers or similar tool, before

withdrawing. To remove a retaining-only clip,

lift the lug on the side of the clip using a

screwdriver, then turn the clip using pliers or

similar tool, before withdrawing.

28 Refitting is a reversal of the removal

procedure. On completion, check the auxiliary

light beam alignment as described in Section 8.

8

Headlight and auxiliary light

beam alignment - checking

and adjustment

2

1 Accurate adjustment of the headlight and

auxiliary light beams is only possible using

optical beam-setting equipment, and this

12•10 Body electrical systems

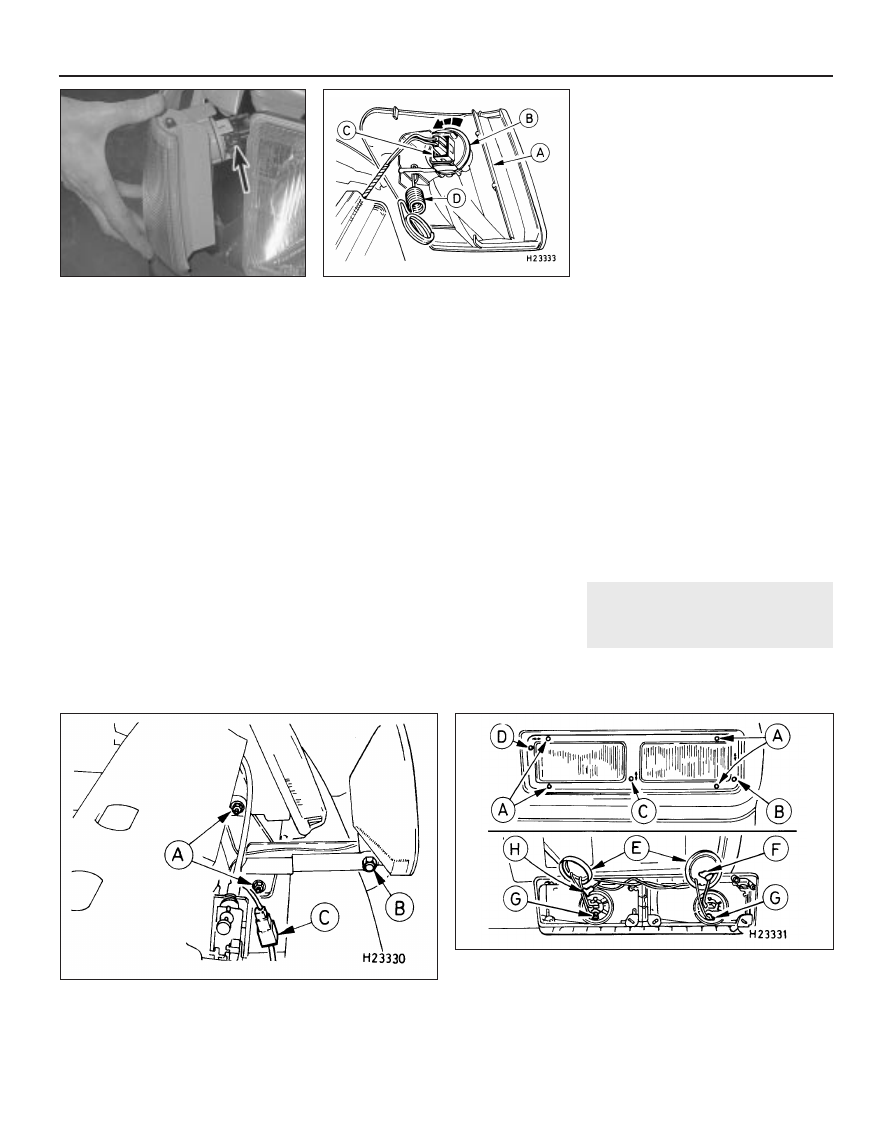

7.24 Auxiliary light assembly (XR2i models) - left-hand unit shown

A Light assembly retaining

screws

B Fog light vertical adjustment

screw

C Driving light vertical adjustment

screw

D Driving light horizontal

adjustment screw

E Bulb protective caps

F Fog light bulb connector

G Bulb earth leads

H Driving light bulb connector

7.21 Auxiliary light fixture (S models)

A Bracket retaining nuts

C Auxiliary light multi-plug

B Auxiliary light retaining nut

7.14 Press the retaining lugs on the rear

light cluster bulbholder together (broken

arrows) to release the bulbholder

7.7b . . . then pull the light unit out to

enable the multi-plug (arrowed) to be

disconnected

1595Ford Fiesta Remake