Dongfeng DFA1101GZ5AD6J-907. Manual - part 66

Electric and Instrument

EL-20

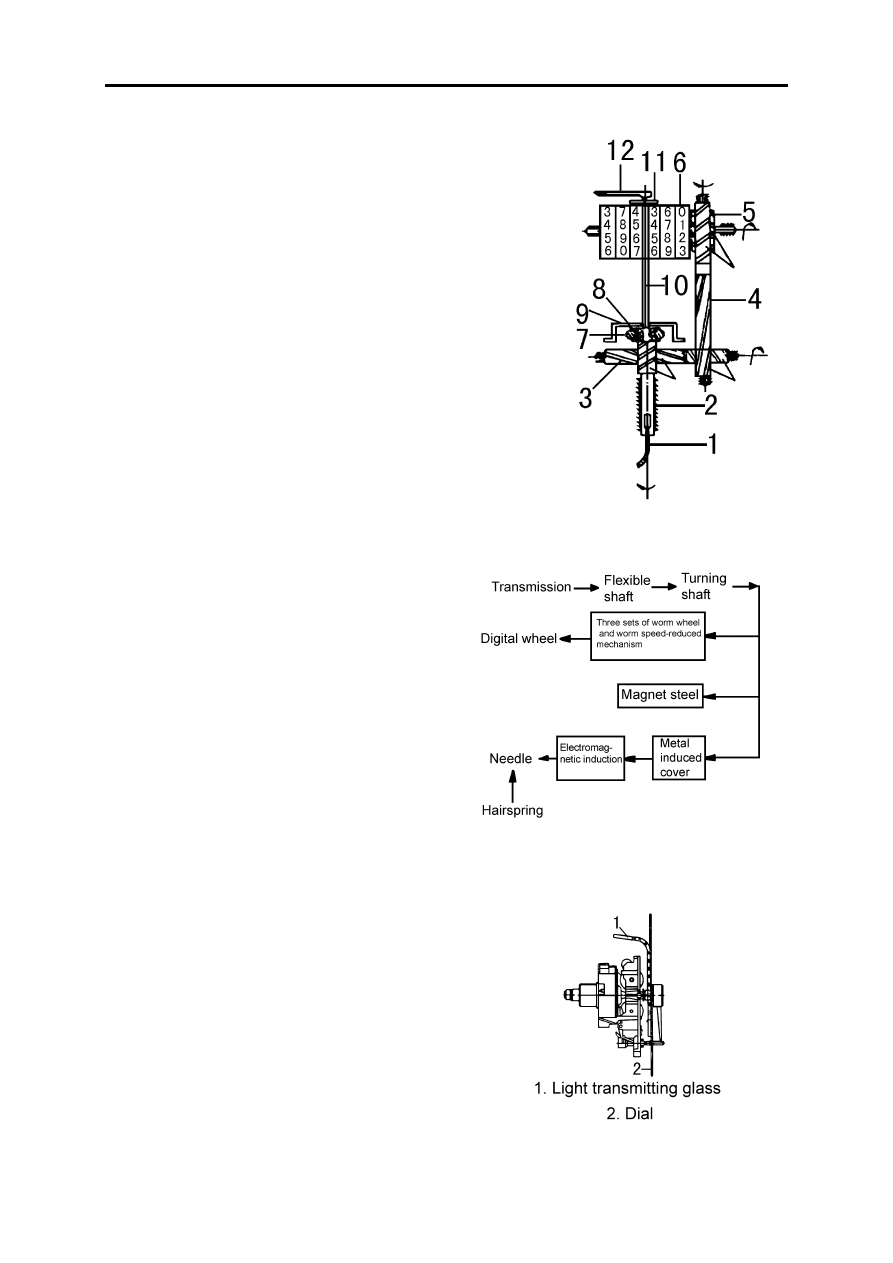

Structure

The speedometer is used to indicate the vehicle driving speed and

the accumulated driving distance. It comprises a speed and a mileage

unit which records vehicle driving mileage. These two units are inte-

grated into one body and driven by the flexible shaft which is connected

with transmission output shaft.

The mileage unit records the driven mileage of the vehicle in order

to do necessary maintenance on mileage. The counter is divided into an

accumulated counter and a day counter. The speed unit indicates the

transient speed of the vehicle. It is convenient to control the vehicle

speed so as to obtain safety, economy and high efficiency.

1.Flexible shaft 2.Drive shaft 3.Worm and lateral shaft

4.Worm and vertical shaft 5.Worm wheel 6.Digital wheel

7.Magnetic ring 8.Temperature compensated ring

9.Inductive aluminum cover 10.Needle shaft

11.Hairspring 12.Needle

Working principle

Drive of speedometer

The flexible shaft (driven by transmission main

shaft) mounted on the back of the transmission is driven

by pulling the square connector into the square hole at

the outside of the speedometer turning shaft which drives

the digital wheel through three sets of worm wheel and

worm.

Indication of odometer

When the flexible shaft drives the speedometer turn-

ing shaft to rotate, the magnetic steel on the drive shaft

rotates simultaneously, causing the eddy current within

the inductive cover, which also produce magnetic field.

Both fields interact on each other to produce deflecting

torque. The higher the vehicle speed is, the larger the

deflecting torque is, which can be indicated by the needle

deflection. When the needle deflecting torque of the hair-

spring, the needle will stay at the appropriate speed

value. The needle deflecting angle is proportional to the

speed of the speedometer turning shaft, that is, the vehi-

cle speed, causing the needle to indicate various speed.