Daewoo Musso. Manual - part 298

TRANSFER CASE (PART TIME 4408) 5D1-31

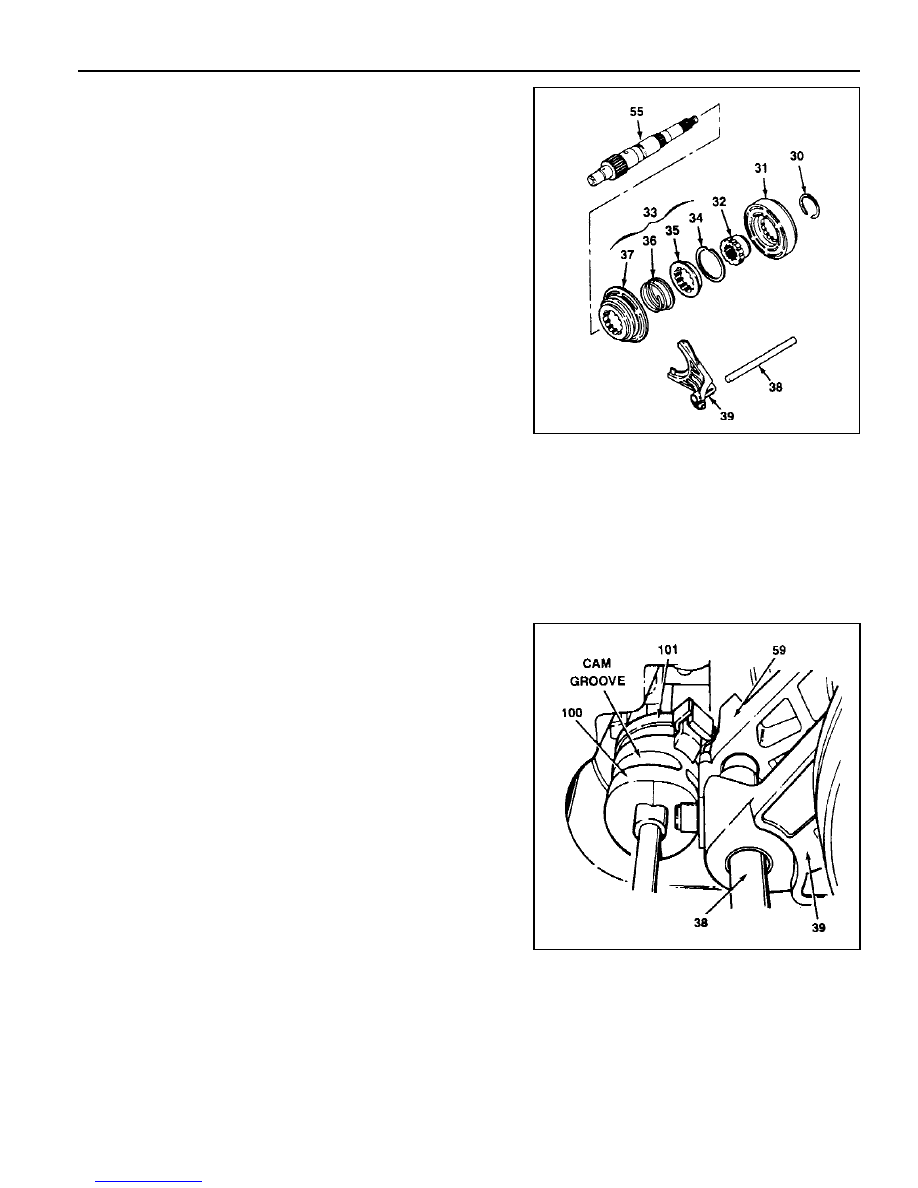

Lockup Shift

1. Install the lockup hub and return spring to the lockup collar

and insert the snap ring.

2. Install the rail shaft through reduction shift fork assembly

previously installed and into the blind hole in case.

3. Engage the lockup fork into the 2WD/4WD groove and

check operation.

4. Install the shift collar hub to the output shaft spline.

5. Install the previously assembled electric shift cam and

assemble the clutch housing as follows.

l

Rotate the shift cam assembly to right so that the end of

the torsion spring contacts with reduction shift fork side.

l

Holding the rail shaft, lift up the fork assembly slightly.

Adjust electric shift cam assembly so that the roller on

reduction shift fork assembly is in groove in shift cam

and button on lockup fork is on cam end.

l

Install the clutch housing over shift collar hub and insert

the retaining ring into the clutch collar hub groove.

30

Retaining Ring

31

Clutch Housing

32

Shift Collar Housing

33

2WD/4WD

Lockup Assembly

34

Snap Ring

38

Rail Shaft

39

Lockup Fork

59

Reduction Shift Fork Assembly

100

Electric Shift Cam

101

Torsion Spring

35

Lockup Hub

36

Return Spring

37

Lockup Collar

38

Rail Shaft

39

Lockup Fork

55

Output Shaft