Daewoo Musso. Manual - part 252

5A-40 AUTOMATIC TRANSMISSION

Converter Clutch Regulator Valve

The converter clutch regulator valve (refer figure 3.20) regulates

the pressure of the oil which applies the converter clutch. Input

oil from the line 500 circuit is regulated within the valve, with

the output pressure being variable according to the signal

pressure from the S5 circuit. Converter clutch apply and release

application is smoothed by electronically varying the S5 circuit

pressure.

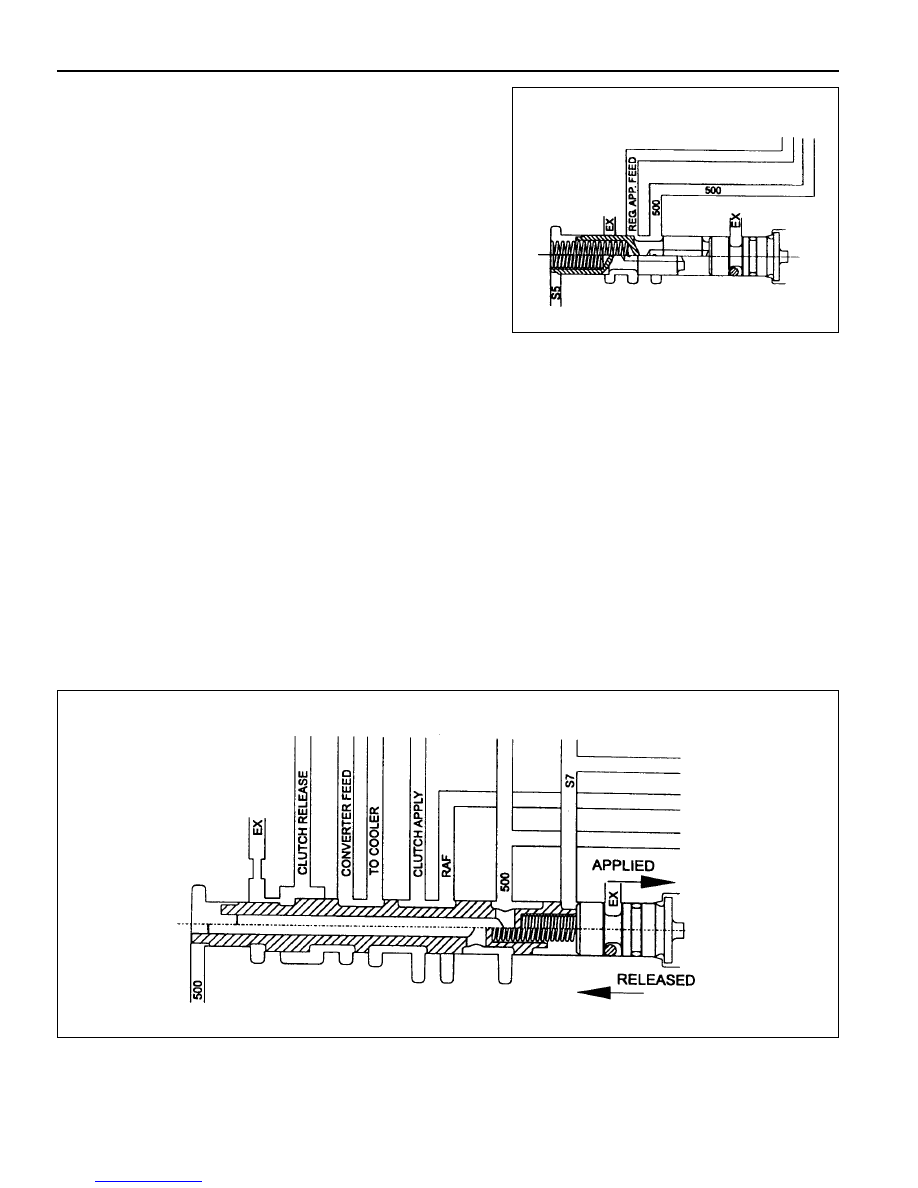

Converter Clutch Control Valve

The converter clutch control valve (refer figure 3.21) is a two position valve which applies or releases the converter

clutch.

The switching of this valve is governed by the signal pressure from S7.

When the valve is in the off or released position, converter feed oil from the PRV is directed to the release side of the

converter clutch. After flowing through the converter, oil returns to the converter clutch control valve and is then

directed to the oil cooler.

When the valve is in the on or applied position, regulated oil from the converter clutch regulator valve is directed to

the apply side of the converter clutch. This oil remains within the converter because the converter clutch piston is

sealed against the flat friction surface of the converter cover. To provide oil flow to the cooler the converter clutch

control valve directs converter feed oil from the PRV directly to the cooler circuit.

Figure 3.21- Converter Clutch Control Valve

Figure 3.20 - Converter Clutch Regulator Valve