Daewoo Musso. Manual - part 202

2A-2 SUSPENSION DIAGNOSIS

Application

Description

4.75 - 5.25

Power Voltage (V)

Axle Vertical

Acceleration

Sensor

(Wheel G

Sensor)

Less than 10

Consuming Current (mA)

Less than 2.0

Output Current (mA)

Operating Characteristics

Type

Damping

Force

Switching

Actuator

3-stage Rotary Step Motor Type

Voltage Rating (V)

DC12

Current Rating (A)

Less than 2.5

Current Time (mS)

95 - 105

4.75 - 5.25

Power Voltage (V)

Body

Vertical and

Lateral

Acceleration

Sensor

Less than 10

Consuming Current (mA)

Less than 2.0

Output Current (mA)

Operating Characteristics

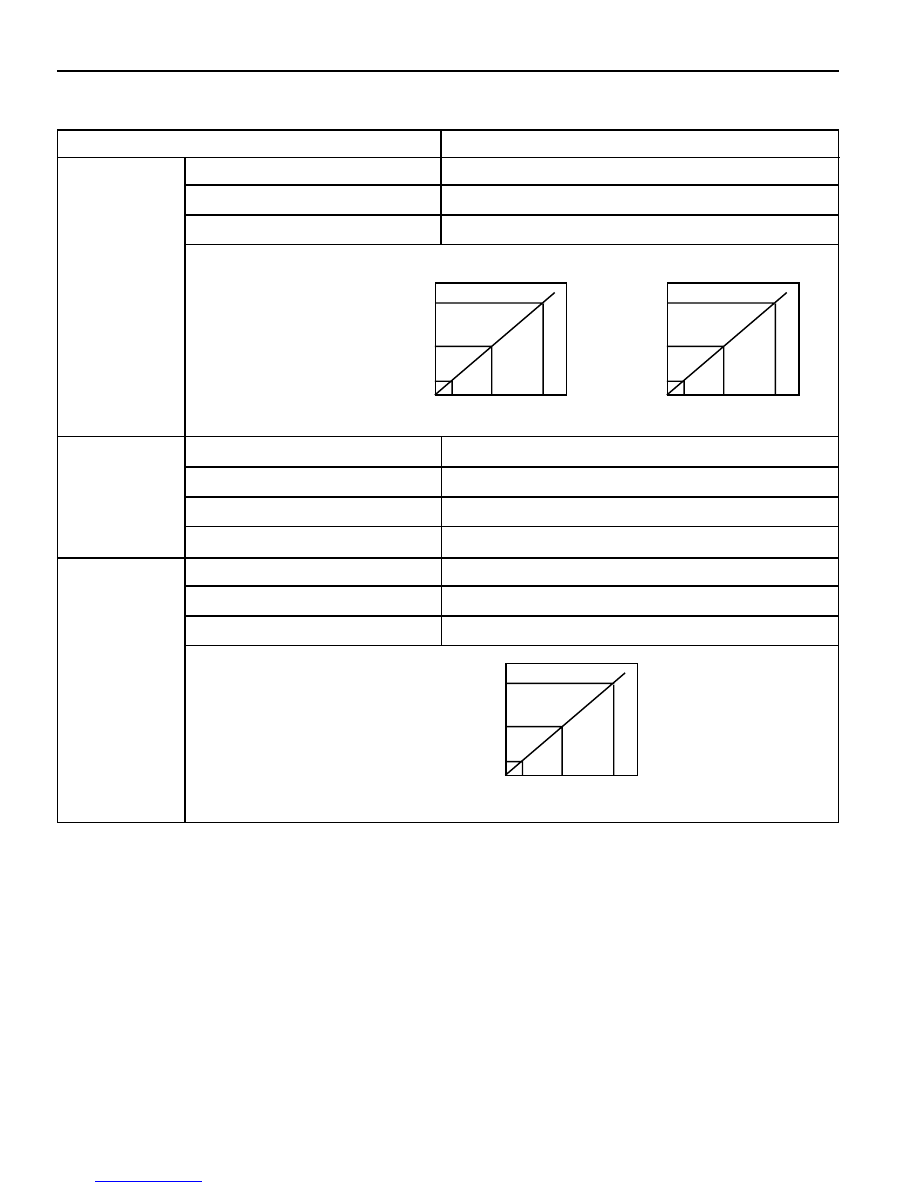

Output Voltage

0.75

2.5

4.25

-1.5g

1g

3.5g

Acceleration

(Vertical Acceleration Sensor)

Output Voltage

0.75

2.5

4.25

-1g

0g

1g

Acceleration

(Lateral Acceleration Sensor)

Output Voltage

0.75

2.5

4.25

-9g

1g

11g

Acceleration

GENERAL SPECIFICATIONS (Cont'd)