Daewoo Musso. Manual - part 103

OM600 ENGINE MECHANICAL 1B3-119

4. Reaming basic bore in cylinder head (repair size).

- Thoroughly remove carbon deposits in cylinder head.

Notice

Particularly remove the insides of the valve seat rings.

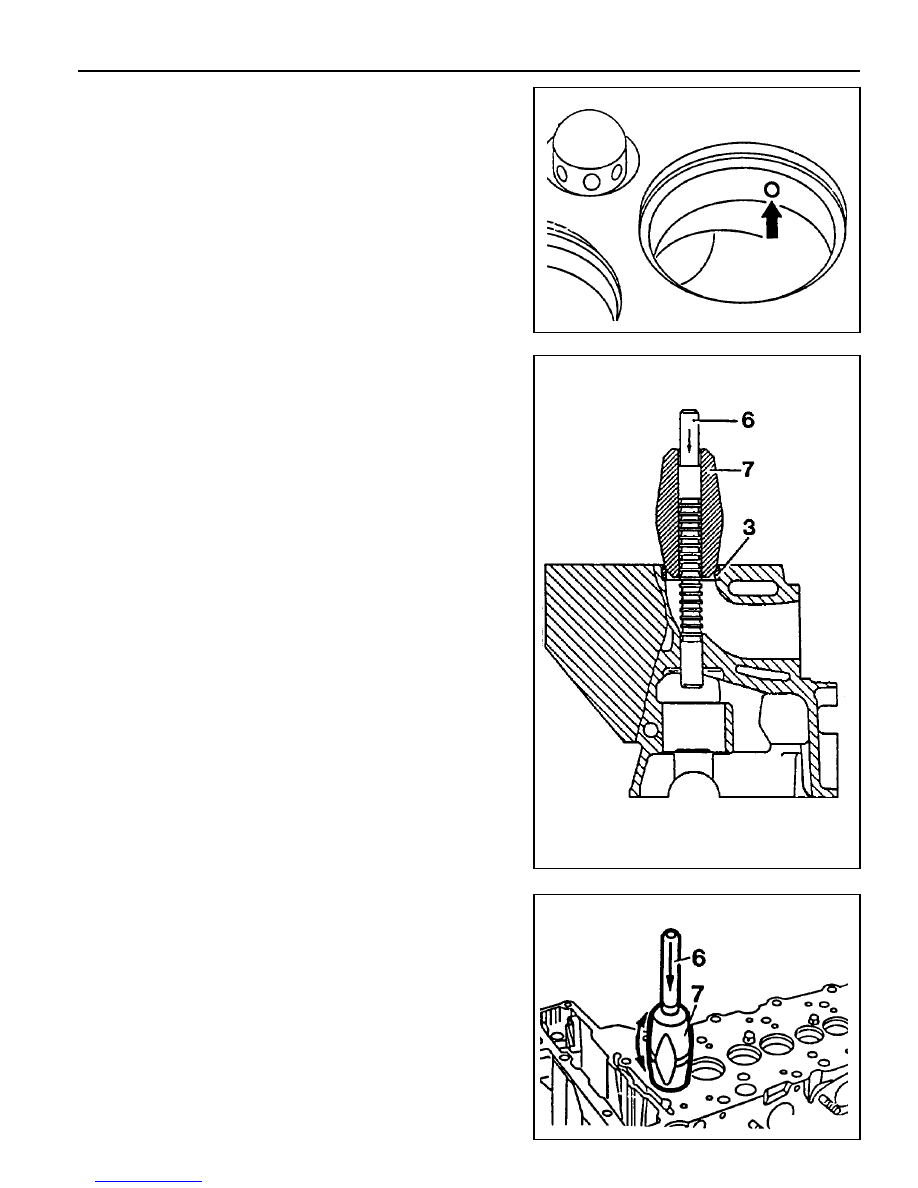

- Remove the elevation (arrow) of intake valve seat rings.

- Select correct broaching tool and guide sleeve (refer to

the table).

Notice

Before broaching work, the broaching tool must be cleared

of swarf with a stiff plastic brush.

- Lubricate the basic bore, guide sleeve and broaching tool

with petroleum.

- Push broaching tool (6) in broaching direction (arrow) into

the guide sleeve (7) far enough so that the first cut of the

broaching tool is positioned in the basic bore when guide

sleeve is fitted onto the valve seat ring (3).

6. Broaching tool

7. Guide sleeve

See the ‘standard data’

- Center the guide sleeve (7) in the valve seat ring (3) by

turning.

- Knock through the broaching tool (6) with a plastic hammer

(approx. 25g). and aluminum drift.