Daewoo Musso. Manual - part 15

GENERAL ENGINE INFORMATION 1A3-11

28bar

Approx.18bar

Max. 3bar

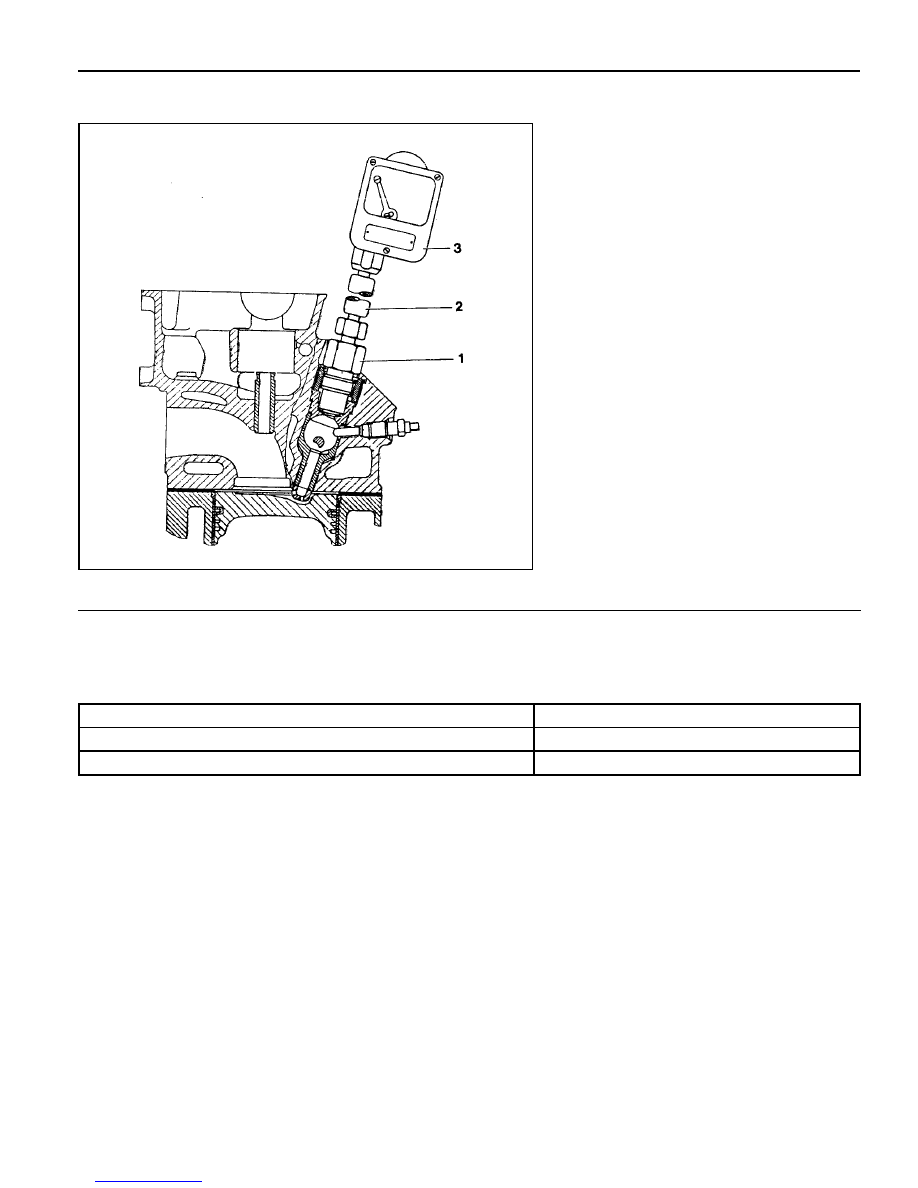

COMPRESSION PRESSURE TEST

1 Test Adapter

2 Flexible Connector

3 Compression Pressure Recorder

Tools Required

000 589 65 09 00 Socket

001 589 73 21 00 Hand Vacuum Pump

Service Data

Normal Compression Pressure

Minimum Compression Pressure

Permissible Pressure Difference Between Individual Cylinders

l

Engine at normal operating temperature of 80°C