Daewoo Matiz (2003 year). Manual - part 162

FIVE-SPEED MANUAL TRANSAXLE 5B – 31

D13B727A

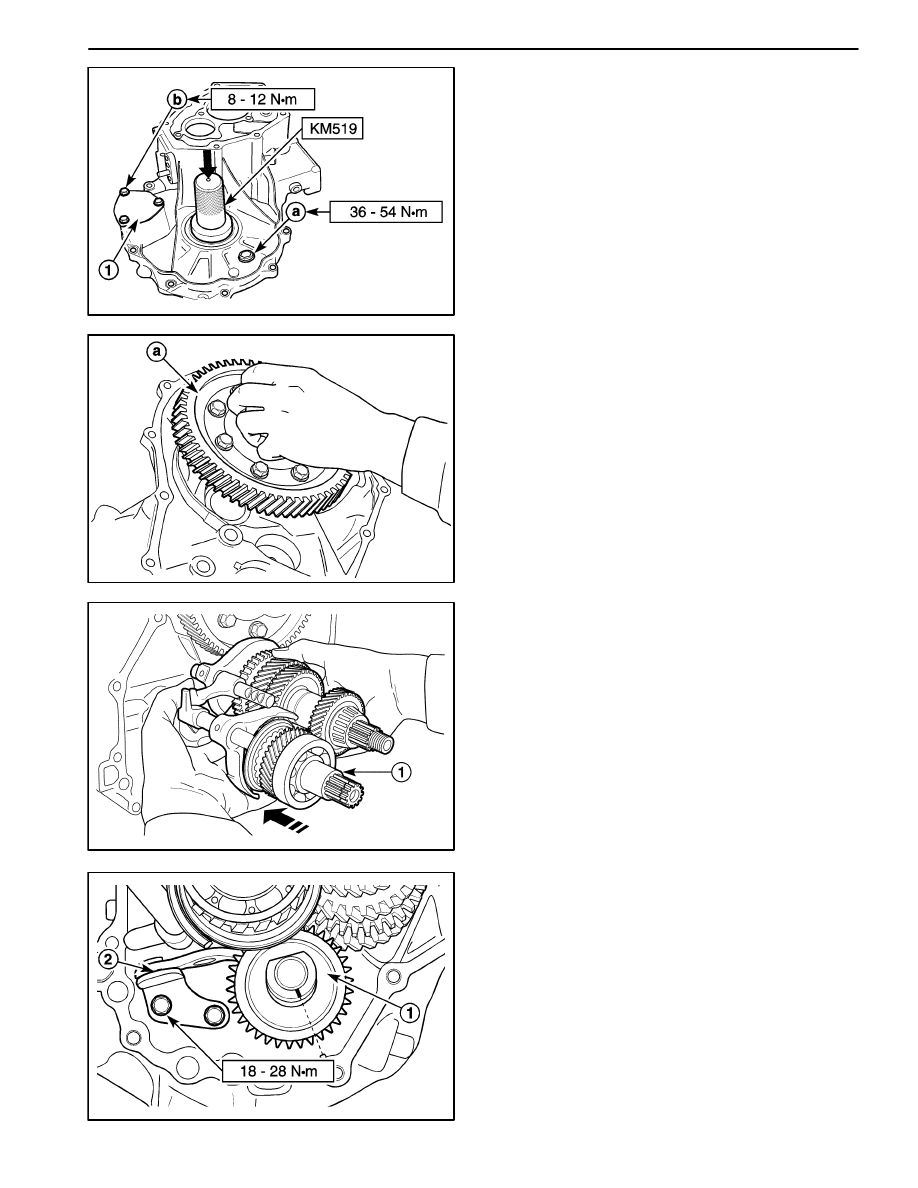

Tighten

Tighten the bolt to 8–12 N

S

m (71–106 lb-in).

b. Case cap retaining bolt.

D

Install the differential left side oil seal using the oil,

seal installer KM519.

D103B728

3. Install the differential assembly to the right side of

transaxle case.

a. Differential assembly.

D

When the differential ring gear surface is lower

than the right side of transaxle case surface, it is

installed correctly.

D103B729

4. Install the low and the high speed shift shaft assem-

bly to the gear unit.

5. Install the gear unit.

D

Push the gear unit by matching it with the input and

the counter shaft hole (1).

Notice: Be careful not to damage teeth of the counter

shaft pinion and the differential ring gear.

D13B730A

6. Install the fifth–reverse gear shift shaft.

7. Install the reverse idle gear shaft assembly and the

reverse gear shift lever.

D

Install the reverse idle gear shaft assembly (1).

Important: Match the marking of the reverse idle gear

shaft bolt hole with the protrusion of the transaxle case

(Right Side).

D

Install the reverse gear shift lever (2).

Tighten

Tighten the bolts to 18–28 N

S

m (13–21 lb-ft).