Daewoo Matiz (2003 year). Manual - part 137

4E – 8 REAR DRUM BRAKES

D107C508

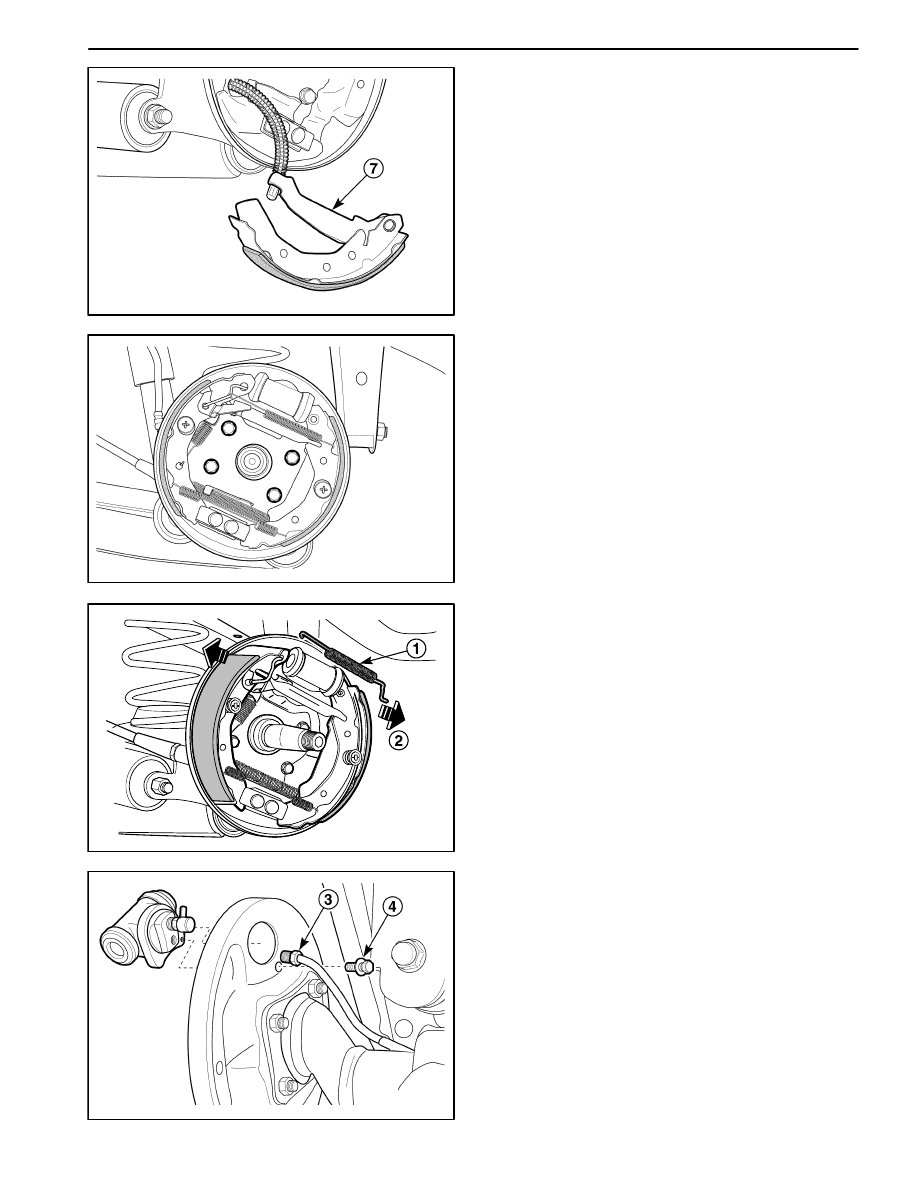

4. Disconnect the parking brake cable from the trailing

shoe and remove the trailing shoe (7).

D107C509

Installation Procedure

1. Install in the reverse of removal.

2. Clean the adjust assembly and apply grease.

3. Connect the parking brake cable from the trailing

shoe.

4. Install the brake shoe.

5. Install the return spring.

D

Install the middle return spring and adjust lever.

D

Install the lower return spring.

D

Install the upper return spring bracket.

D

Install the upper return spring.

6. Install the brake drum. Refer to “Brake Drum” in this

section.

D107C510

WHEEL CYLINDER ASSEMBLY

Removal Procedure

1. Remove the brake drum. Refer to “Rear Brake Drum”

in this section.

2. Remove the wheel cylinder.

D

Remove the brake shoe upper spring (1).

D

Widen the leading shoe and trailing shoe (2).

D107C511

D

Disconnect the brake line fitting (3).

D

Plug the opening in the brake line to prevent fluid

loss or contamination.

D

Remove the wheel cylinder–to–backing plate bolt

(4).