Daewoo Matiz (2003 year). Manual - part 97

1F – 298 ENGINE CONTROLS

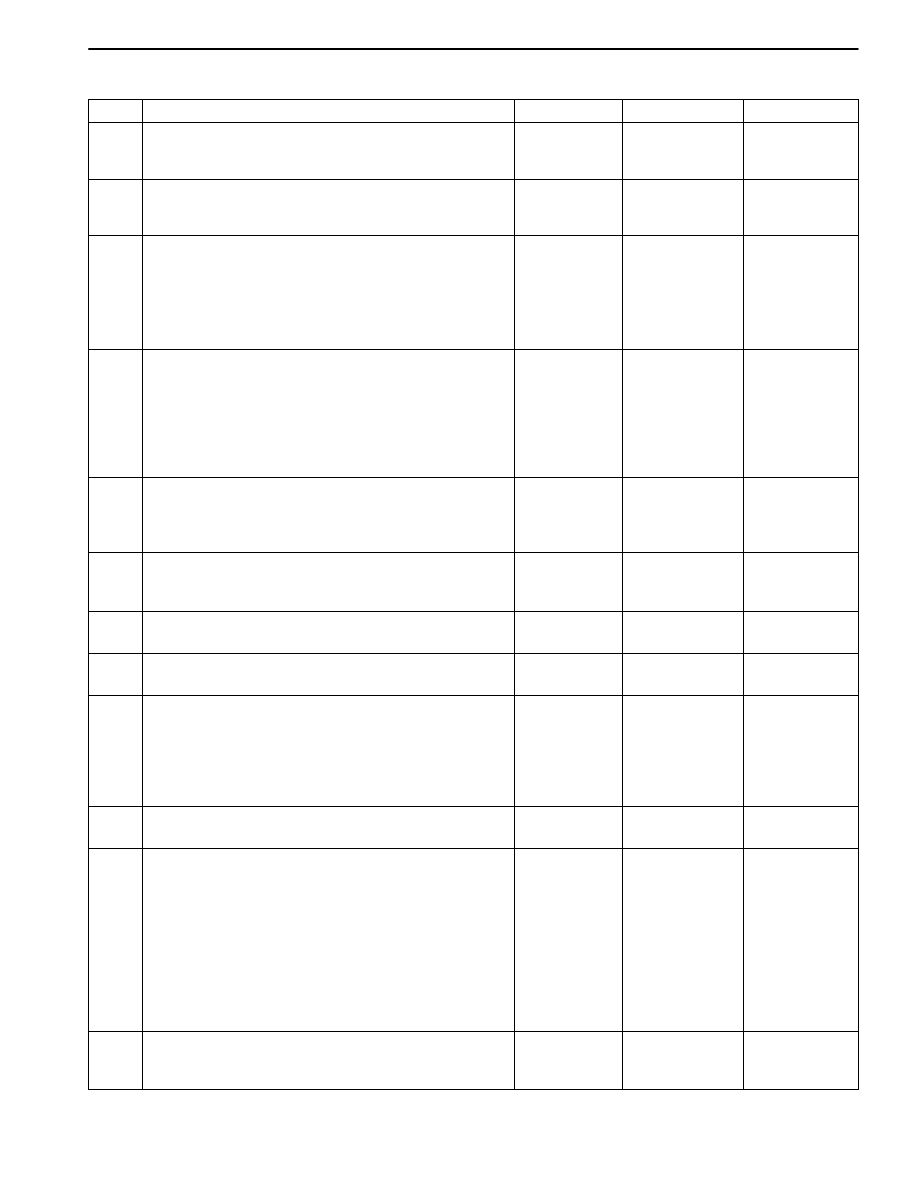

Rough, Unstable, or Incorrect Idle, Stalling (Cont’d)

Step

Action

Value(s)

Yes

No

12

Is the long term fuel trim reading below the value

specified?

–20%

Go to

“Diagnostic Aids

for DTC P0172”

Go to Step 13

13

Is the long term fuel trim reading above the value

specified?

25%

Go to

“Diagnostic Aids

for DTC P0171”

–

14

1. Disconnect all of the fuel injector harness

connectors at the fuel injectors.

2. Connect an injector test light between the

harness terminals of each fuel injector connector.

3. Note the test light while cranking the engine.

Does the test light blink for all of the fuel injectors?

–

Go to Step 16

Go to Step 15

15

1. Repair or replace the faulty injector drive circuit

harness, the connector, or the connector

terminals as needed.

2. If the harness, the connectors, and the terminals

are OK, replace the Engine Control Module

(ECM).

Is the repair complete?

–

System OK

–

16

Measure the resistance of each of the fuel injectors.

Is the resistance within the value specified (the

resistance will increase slightly at higher

temperatures)?

11.6–12.4

Ω

Go to Step 18

Go to Step 17

17

Replace any fuel injectors with a resistance that is

out of specifications.

Is the repair complete?

–

System OK

–

18

Perform an injector diagnosis.

Is the problem found?

–

Go to Step 19

Go to Step 20

19

Replace any leaking or restricted fuel injectors.

Is the repair complete?

–

System OK

–

20

1. With the engine OFF, disconnect the fuel

pressure regulator vacuum hose.

2. Thoroughly inspect the fuel pressure regulator

vacuum port and the fuel pressure regulator

vacuum hose for the presence of fuel.

Is the problem found?

–

Go to Step 21

Go to Step 22

21

Replace the fuel pressure regulator as needed.

Is the repair complete?

–

System OK

–

22

1. Check the ignition system output voltage for all of

the cylinders using a spark tester.

2. Inspect the spark plugs for excessive wear,

insulation cracks, improper gap, or heavy

deposits.

3. Inspect the ignition wires for cracking, hardness,

or improper connections.

4. Replace any ignition wires with a resistance over

the value specified.

Is the problem found?

30000

Ω

Go to Step 23

Go to Step 24

23

Repair or replace any ignition system components

as needed.

Is the repair complete?

–

System OK

–