Daewoo Matiz (2003 year). Manual - part 6

SOHC ENGINE MECANICAL 1B – 7

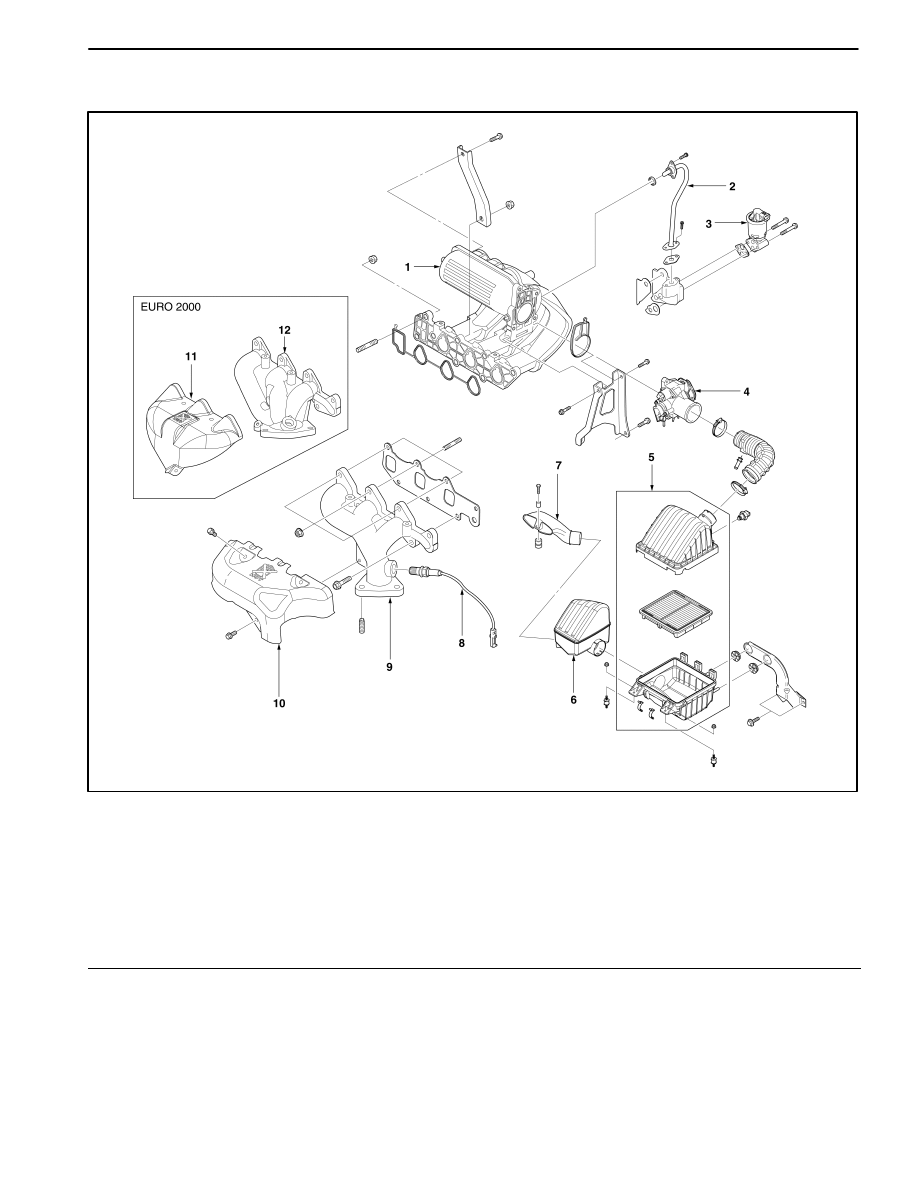

MANIFOLD & AIR FLOW SYSTEM

D21B0021

1 Intake Manifold

2 Exhaust Gas Recirculation (EGR) Pipe

3 Exhaust Gas Recirculation (EGR) Valve and

Solenoid

4 Throttle Body Assembly

5 Air Filter Assembly

6 Resonator

7 Snorkel

8 Oxygen Sensor

9 Exhaust Manifold

10 Exhaust Manifold Heat Shield

11 Exhaust Manifold Heat Shield (Euro III)

12 Exhaust Manifold (Euro III)