Daewoo Korando. Manual - part 254

AUTOMATIC TRANSMISSION 5A-59

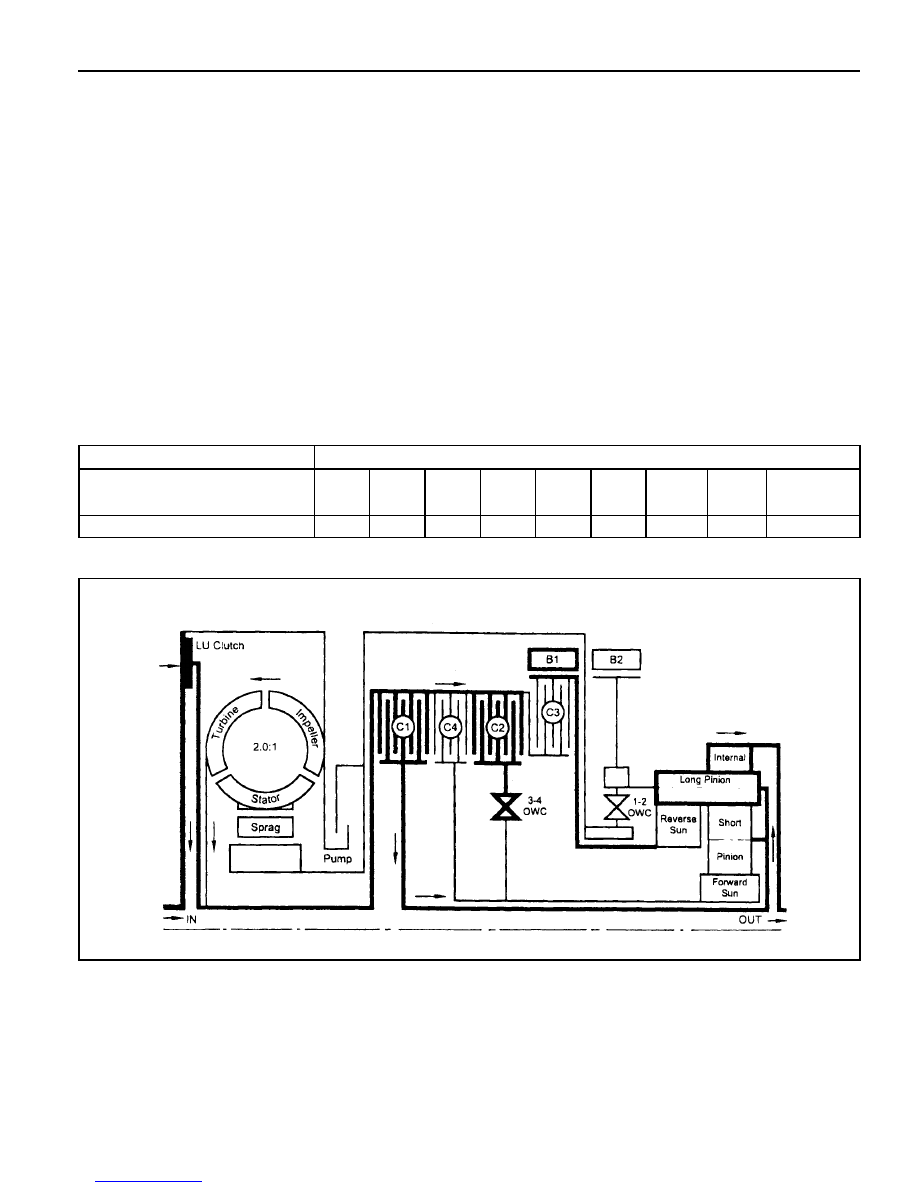

POWER FLOW - DRIVE 4 LOCK UP

In Drive 4 Lock Up, transmission drive is the same as for Drive 4 but with the application of the converter lock up clutch

to provide positive no-slip converter drive.

Control

Control for Drive 4 Lock Up is the same as for Drive 4 with the addition of the converter clutch circuit activated by

solenoid S7.

l

When S7 is switched On, S7 feed oil to the converter clutch control valve is switched off and allowed to exhaust

through the S7 solenoid. This allows the valve to move to the clutch engage position.

l

Regulated apply feed oil, delved from Line 500 oil at the converter clutch regulator valve, is directed by the

converter clutch control valve to the engage side of the converter clutch.

l

Converter clutch release oil is exhausted at the converter clutch control valve.

l

Converter feed oil is re-routed by the converter clutch control valve directly to the oil cooler and lubrication

circuit.

Refer to figure 5.9 arid table 5.10.

Table 5.10 - Engaged Elements - Drive 4 Lock Up

Gear State

Drive 4 Lock Up

C1

X

C2

X

C3

-

C4

-

B1

X

B2

-

1-2

OWC

-

3-4

OWC

-

LU

CLUTCH

X

ELEMENTS ENGAGED