DAF LF45, LF55 Series. Manual - part 464

©

200436

3-7

Removal and installation

BRAKE SYSTEM AND COMPONENTS

ΛΦ45/55 series

6

4

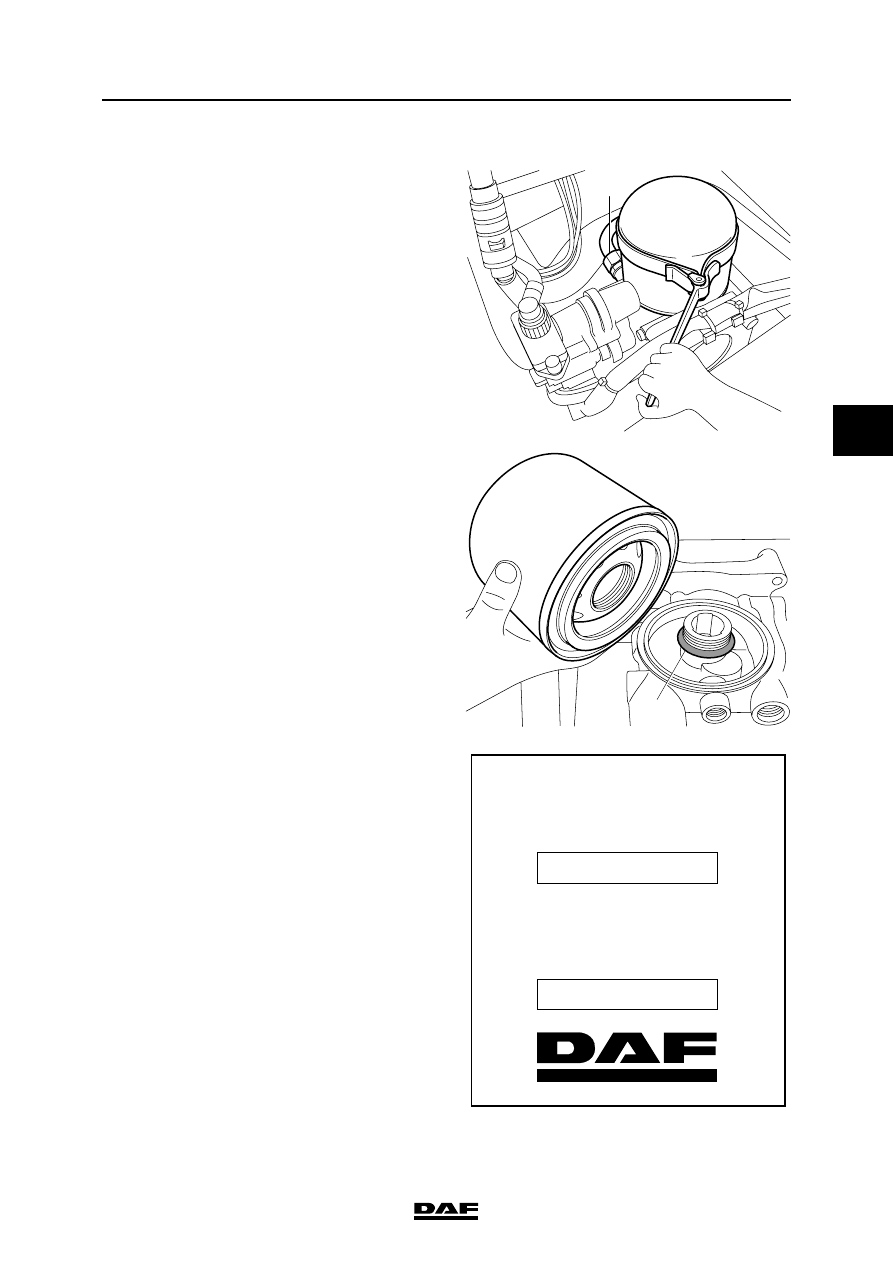

Removing air dryer filter element

1.

Bleed the air dryer by allowing it to

regenerate or by loosening the compressor

pipe (1), so that the interior of the air dryer is

depressurised.

2.

Remove the filter element by turning it anti-

clockwise using a filter strap spanner.

3.

The filter element should be disposed of as if

it were an oil filter.

4.

Clean the air dryer internally.

5.

Check the air dryer threaded connection (2)

for damage and then lubricate it sparingly

with grease.

Installing the air dryer filter element

1.

Lubricate the sealing ring of the new filter

element sparingly with grease.

2.

Fit the filter element by manually tightening it

until the sealing ring abuts. Then tighten the

filter element by hand (approx. 1 turn).

3.

Fasten the compressor line (1).

4.

Pressurise the system and then check the air

dryer for air leaks.

5.

Fill in the date on the sticker with a

waterproof felt pen by which the filter

element must be replaced (max. 1 year after

fitting).

R600525

1

R600526

2

Artikelnummer

Reference

Teilenummer

Référence

Eerstvolgende vervanging

Next change

Nächster Wechsel

Prochain remplacement

1391510

R600523