DAF LF45, LF55 Series. Manual - part 457

©

200436

2-7

Inspection and adjustment

BRAKE SYSTEM AND COMPONENTS

ΛΦ45/55 series

6

4

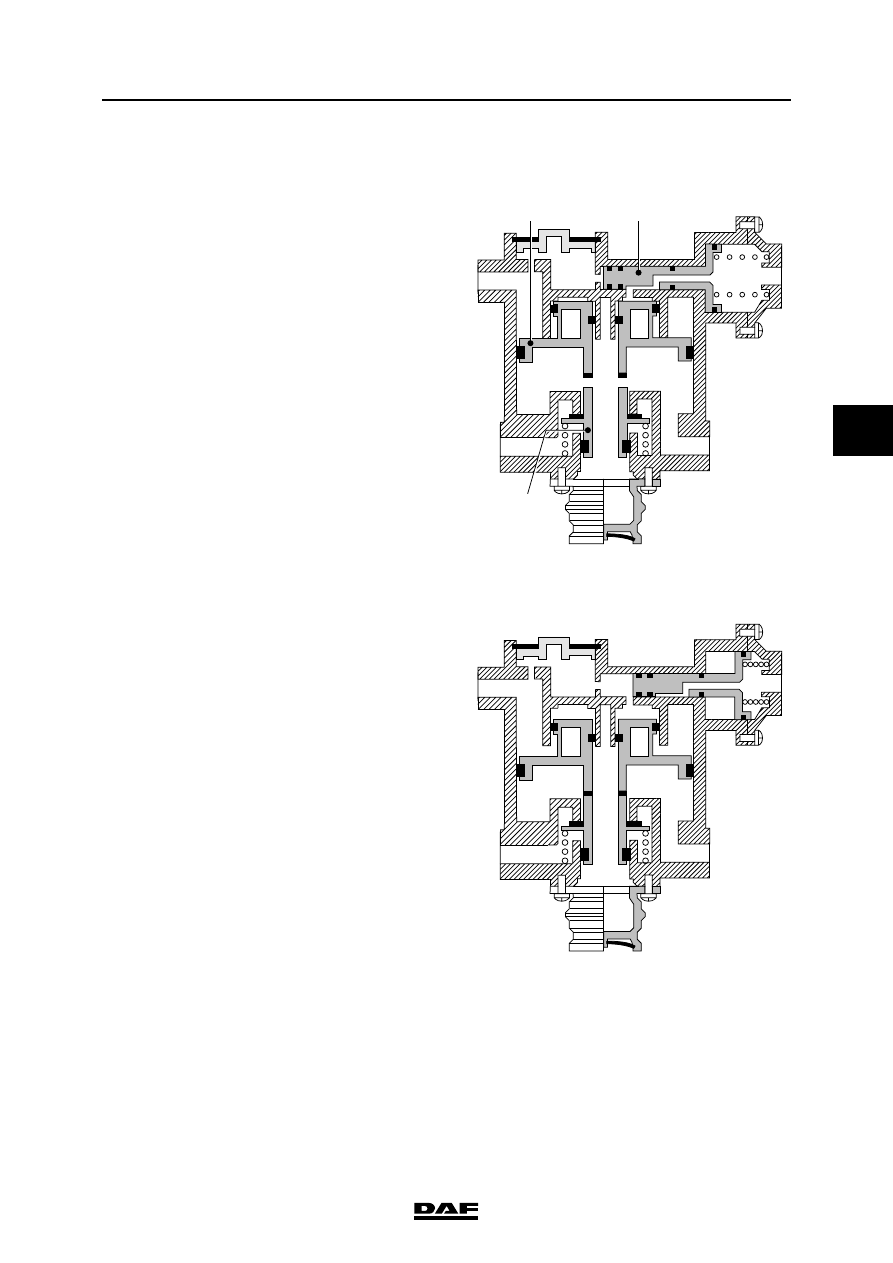

2.5 INSPECTION EMPTY/LOAD RELAY VALVE

1.

Using a T-piece, connect a pressure gauge

to connecting point 41.

2.

Connect a pressure gauge to the test

connection on one of the brake chambers of

the front axle.

3.

Connect a pressure gauge to the test

connection on one of the brake chambers of

the rear axle.

4.

Pressurise the system.

Testing when empty

1.

Set the load sensing valve to the empty

position.

2.

Slowly depress the brake pedal.

The pressure on the front axle should rise

gradually, not in jumps.

The pressure on the front axle will rise less

quickly than that on connecting point 41.

(With an empty vehicle, the difference will be

greater than with a partially loaded vehicle).

1

2

3

42

41

R600904

4

6

5

1

2

3

42

41

R600905