DAF LF45, LF55 Series. Manual - part 452

©

200436

2-29

Description of components

OPERATION OF BRAKE COMPONENTS

ΛΦ45/55 series

6

3

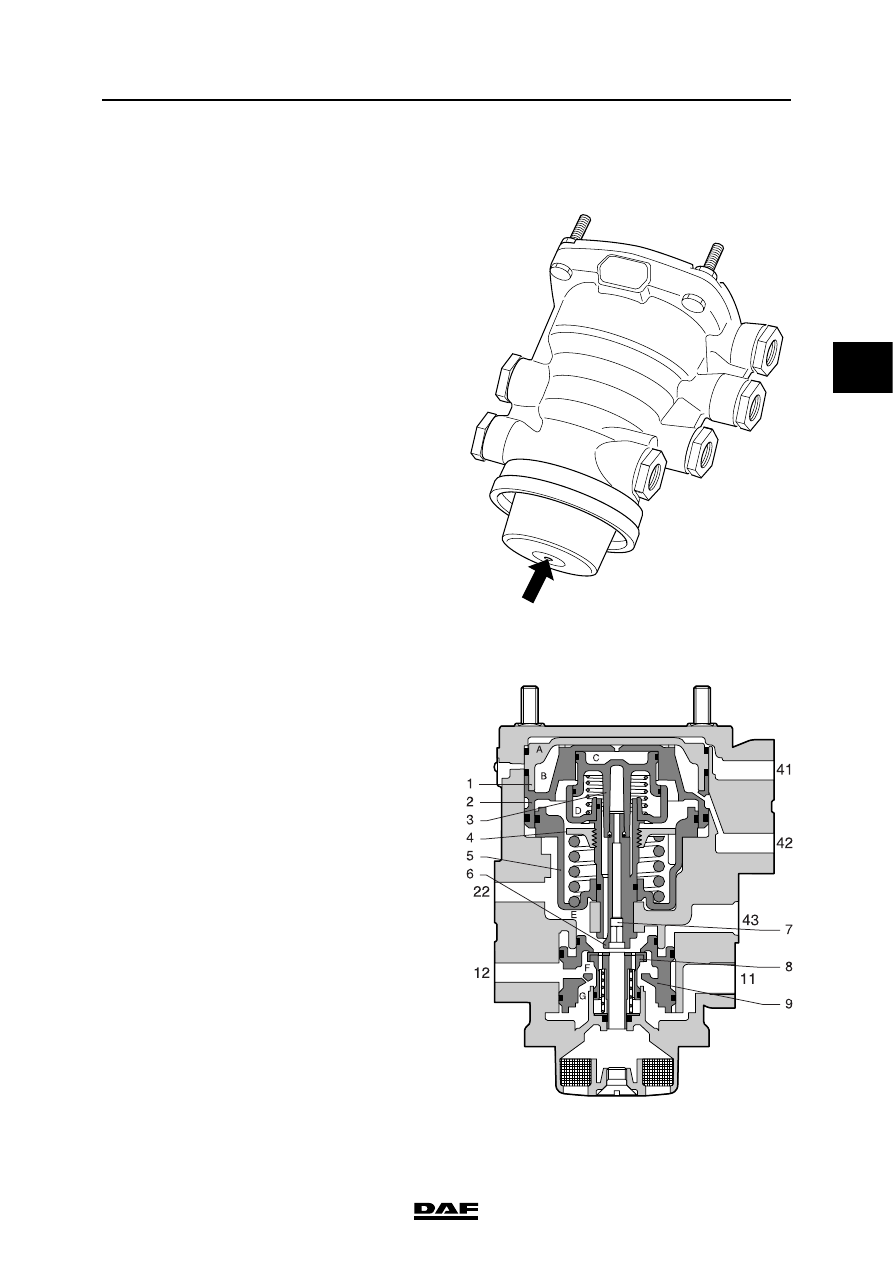

2.16 TRAILER CONTROL VALVE

Purpose

The purpose of the trailer vehicle control valve is

to pass on the brake commands from the prime

mover to the trailer vehicle.

Operation

Driving

Connecting point 11 is connected to a reservoir

and connecting point 43 to the parking brake

valve. Both are pressurised and in a state of

equilibrium. The service coupling head

communicates with the ambient air via

connecting point 22, valve 8 and the bleed vent

with damper.

41

42

43

11

12

22

R600335

R600340