DAF LF45, LF55 Series. Manual - part 447

©

200436

2-9

Description of components

OPERATION OF BRAKE COMPONENTS

ΛΦ45/55 series

6

3

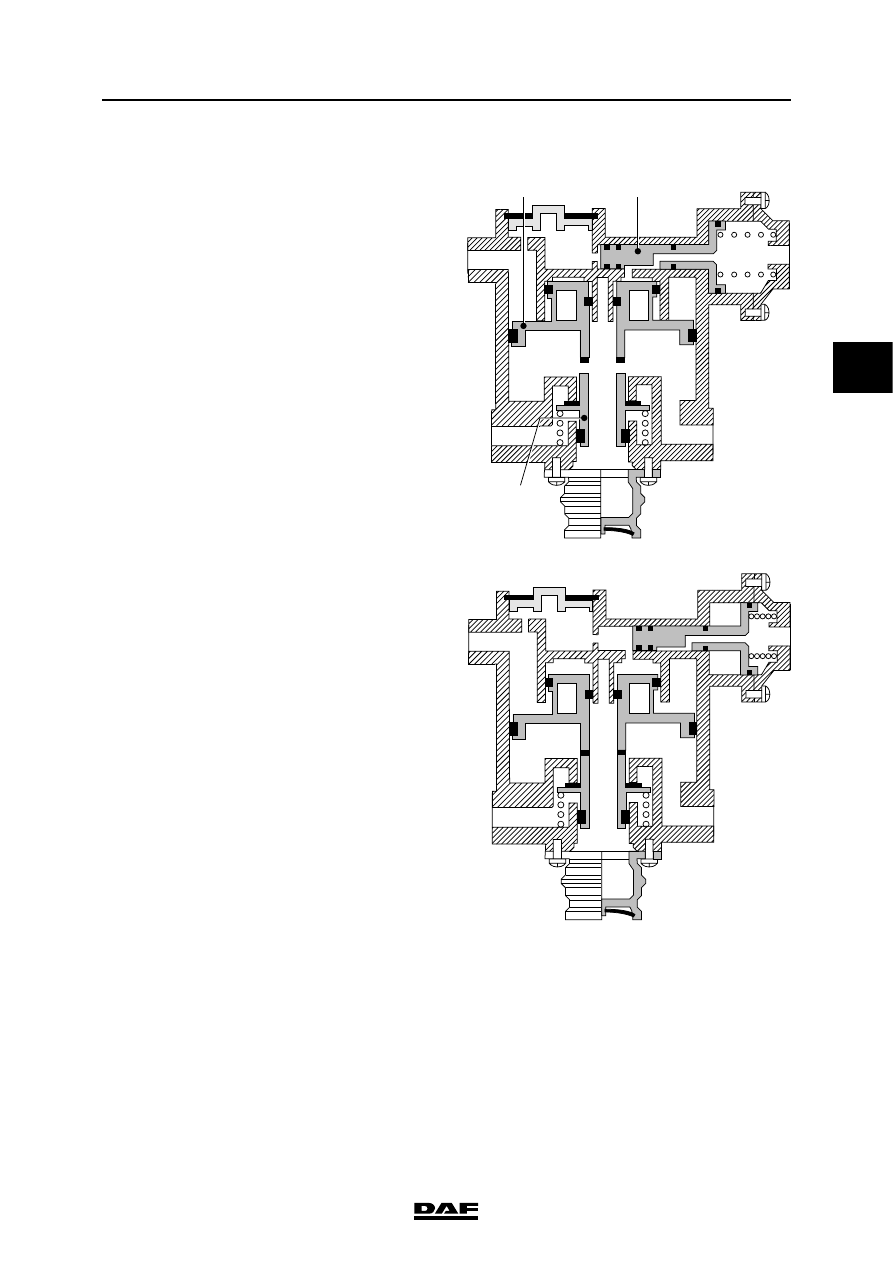

Empty/load relay valve

In rest position, relay piston 4 is in its upper

position and connecting point 2 (brake cylinders

on front axle) is bled via connecting point 3.

When the foot brake is applied, the relay piston is

forced downwards via connecting point 41, thus

opening valve 5. At connecting point 2 pressure is

built up until a set value is reached. Relay piston

4 is then once again forced upwards until there is

a state of equilibrium.

Air has also entered simultaneously via

connection point 42 (load sensing valve). This will

force piston 6 to the left. Through a bore in piston

6 the pressure now also reaches the central

surface of the relay piston (4). This pressure will

depend on the loading of the rear axle. As a

consequence, the output pressure of this valve is

in part dependent on the braking pressure of the

rear axle.

The input pressure at connecting point 41 is also

applied to the left-hand side of piston 6, via two

openings. If no pressure enters via connecting

point 42, due to a fault, piston 6 will be forced to

the right. The pressure at connecting point 41 will

now also reach the central surface of relay piston

4. In this situation, the valve simply operates as a

relay valve, and will no longer reduce.

When the foot brake is released, the pressure at

connecting points 41 and 42 will disappear. Relay

piston 4 will be forced upwards by the pressure

beneath it, thus opening the bleed system.

1

2

3

42

41

R600493

4

6

5

1

2

3

42

41

R600494