DAF LF45, LF55 Series. Manual - part 226

©

200508

4-5

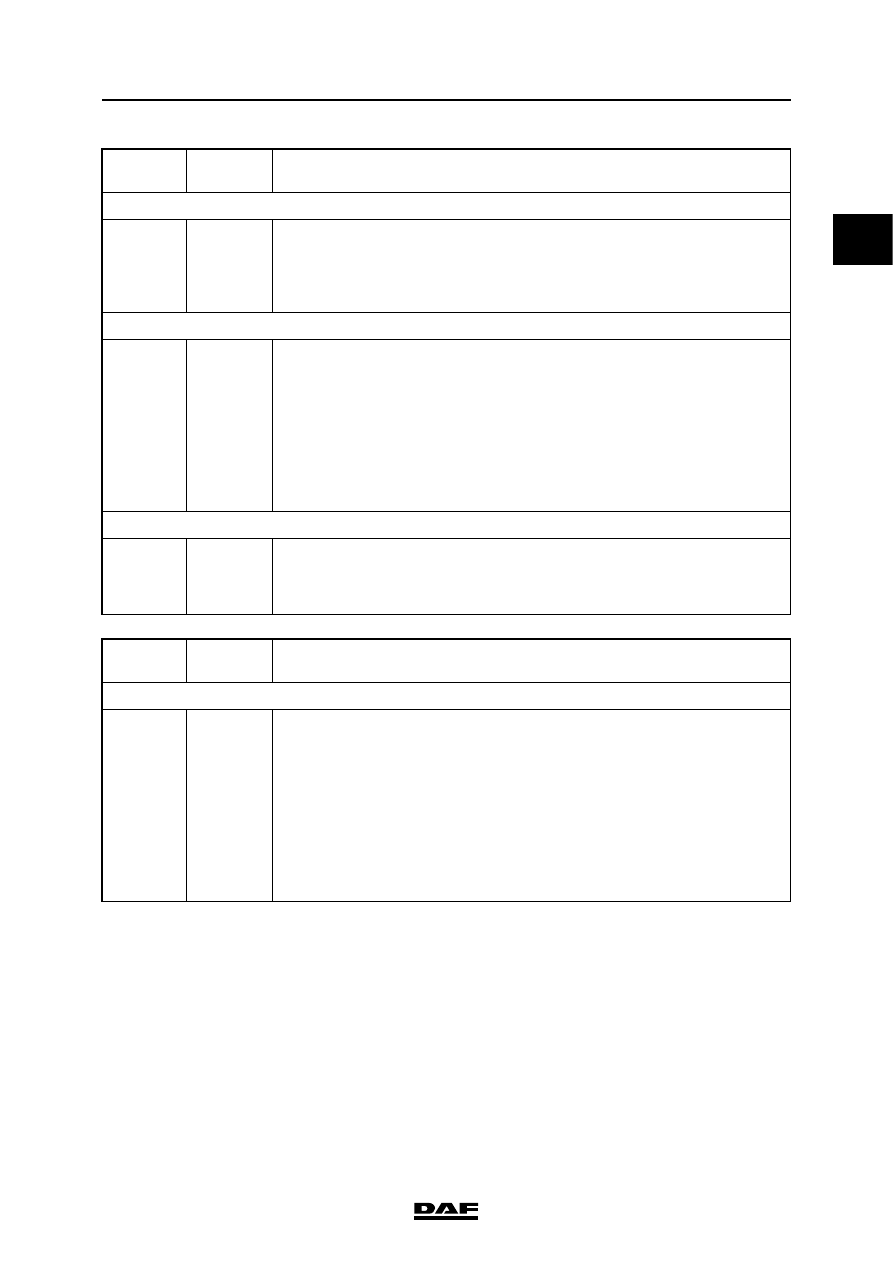

Automatic gearbox

DIAGNOSTICS

ΛΦ45/55 series

3

1

EEPROM fault

34

12

13

14

15

16

1.

Re-calibrate if necessary.

2.

If re-calibration is impossible, replace the ECU.

3.

If ECU replacement is impossible, contact your Allison dealer.

EEPROM writing error as a result of loss of power supply

35

00

16

Check the following points:

1.

ECU is firmly attached, clean and undamaged.

2.

VIM (Vehicle Interface Module) is firmly attached, clean and undamaged.

3.

the vehicle manufacturer has used the specified wiring for power supply

and earth connection.

4.

battery positive pole.

5.

battery earth connection.

6.

specified connections for vehicle ignition.

If all these points are in order, contact your Allison dealer.

Hardware/software not compatible

36

00

1.

Replace ECU if possible.

2.

Re-program ECU if possible.

3.

If replacement or re-programming is not possible, contact your Allison

dealer.

Main code Sub-code

RECOMMENDED PROCEDURES

Interruption or short circuit in electromagnetic valve circuit

41

12

13

14

15

16

20

22

23

24

25

26

Check the following points:

1.

gearbox main connector is connected, is firmly attached, is clean and

undamaged.

2.

ECU connector is connected, is firmly attached, is clean and undamaged.

3.

visual inspection of the wiring harness: no damage, chafed or too taut

wires, no screws through the wiring harness.

4.

no interruptions or short circuits between wires or earth in wiring harness.

Replace wiring harness if necessary.

If all these points are in order, contact your Allison dealer.

Main code Sub-code

RECOMMENDED PROCEDURES