DAF LF45, LF55 Series. Manual - part 177

©

200505

3-1

Description of components

BE ENGINE COOLING SYSTEM

ΛΦ45/55 series

2

3

3. DESCRIPTION OF COMPONENTS

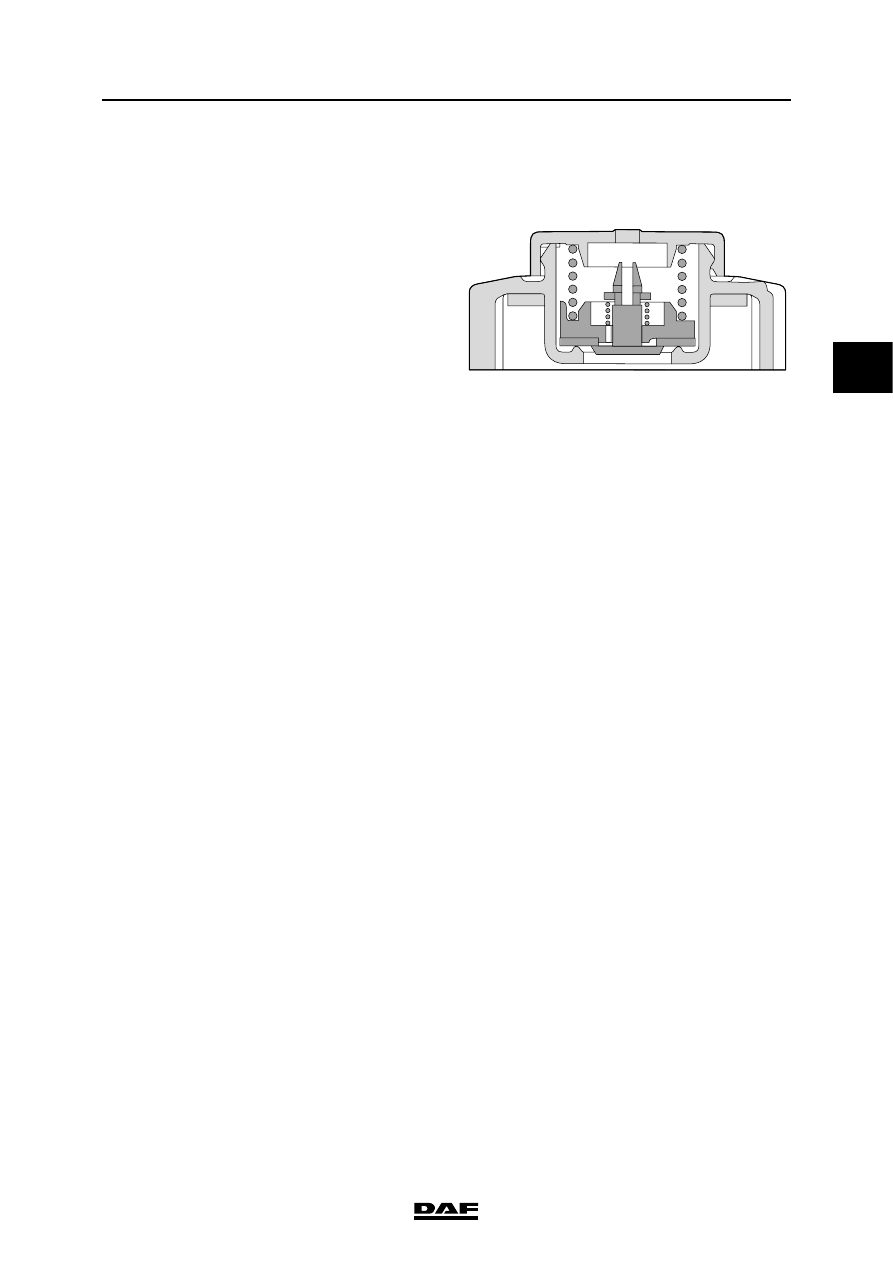

3.1 PRESSURE CAP

The pressure cap is fitted on the header tank by

means of a threaded connection.

To fill the cooling system, there is a filler cap at

the front of the header tank.

The pressure cap has two valves: a pressure

relief valve and a vacuum relief valve.

Normally, both valves are closed.

Overpressure

As a result of the rising coolant temperature, the

pressure (P1) in the cooling system will increase.

If the pressure in the cooling system becomes too

high (0.7 bar), the pressure relief valve (1) will

open against the pressure of the spring.

Negative pressure

If the coolant temperature drops, the pressure

(P1) in the cooling system will decrease. If the

pressure (P1) in the cooling system drops to

approximately 0.1 bar below the ambient air

pressure (P2), the underpressure valve will be

opened.

M201151

P2

P1