DAF LF45, LF55 Series. Manual - part 172

©

200505

4-23

Removing and installing

BE ENGINE

ΛΦ45/55 series

2

2

4.16 REMOVAL AND INSTALLATION, FLYWHEEL HOUSING SEAL

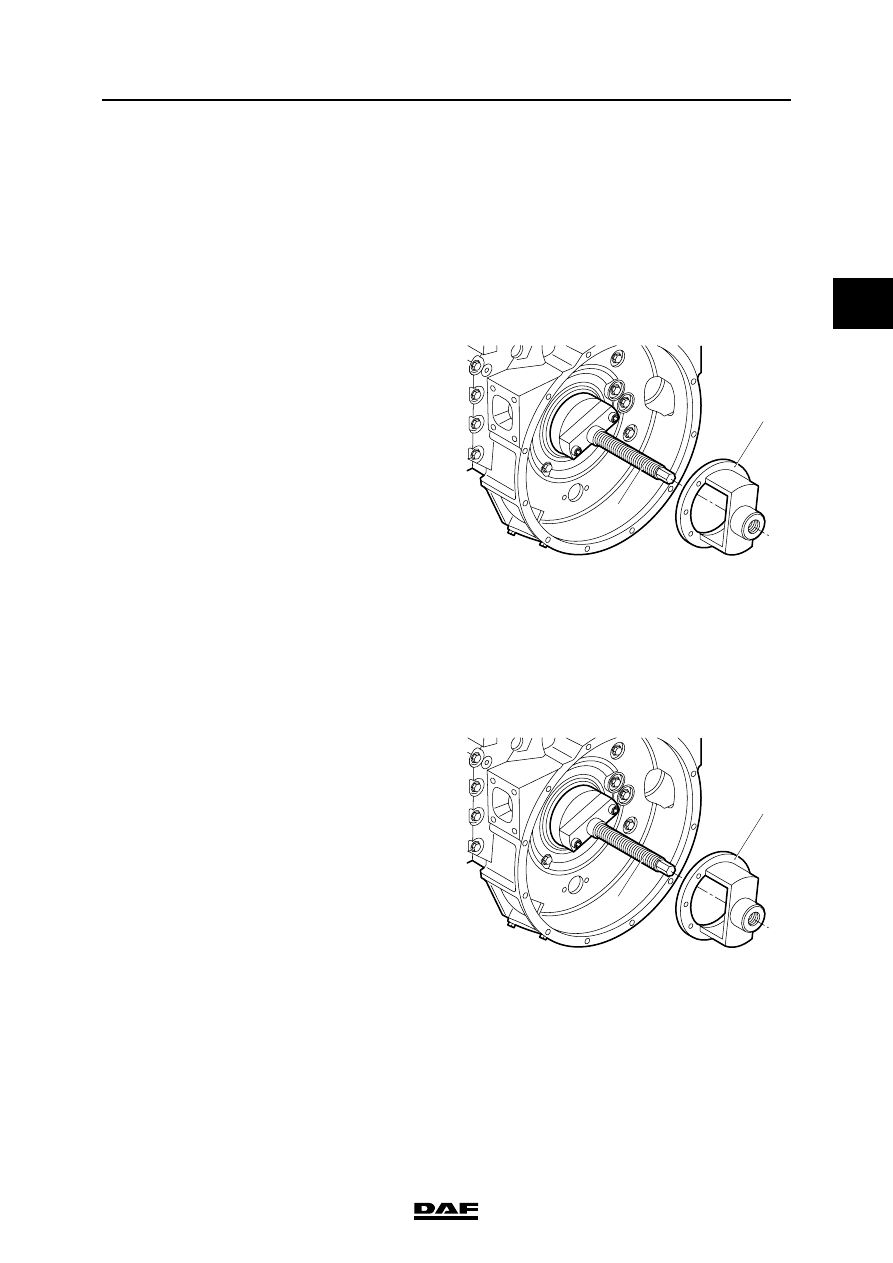

Removing the flywheel housing seal

1.

Remove the gearbox.

2.

Remove the clutch release assembly and the

clutch plate.

3.

Remove the flywheel.

4.

Fit the threaded spindle (2) of the special tool

(DAF no. 1329475) on the crankshaft flange.

5.

Screw the push/pull piece (1) onto the

spindle up to the flywheel housing.

Note:

Mark the drill at a length of 22 mm using a

piece of tape.

6.

Drill a hole through the base plate to the tape

marking and fit a screw in the seal to keep

the base plate in its place.

7.

Drill the other five holes and fit screws.

8.

Turn the threaded spindle (2) clockwise until

the seal has been removed.

Installing the flywheel housing seal

1.

Clean and inspect the seal chamber. Even

minimal damage may cause a leak.

2.

Fit the threaded spindle (2) of the special tool

(DAF no. 1329475) on the crankshaft flange.

3.

Put a new seal over the crankshaft.

4.

Screw the push/pull piece (1) onto the

threaded spindle (2) up to the seal.

5.

Turn the threaded spindle (2) anti-clockwise

until the push/pull piece (1) is level with the

flywheel housing. The seal has been

properly fitted once it is level with the

flywheel housing.

6.

Remove the special tool.

7.

Fit the flywheel.

8.

Fit the clutch plate and the clutch release

assembly.

9.

Fit the gearbox.

M201068

2

1

M201068

2

1