Chery Tiggo 5 (T21). Manual - part 159

13–

7

13

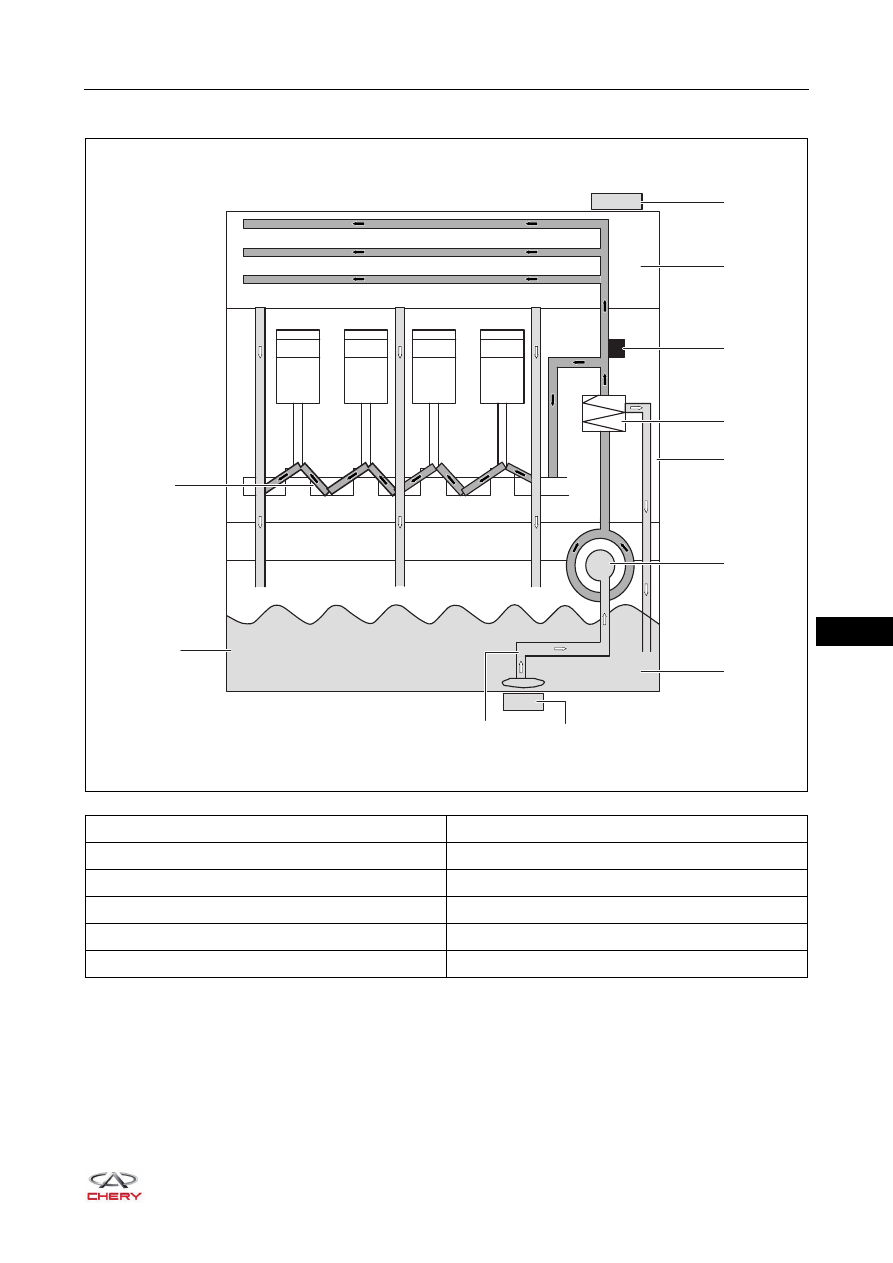

Lubrication System Flowchart

Description

1. Solid arrow: indicates the flow of high-pressure lubricant.

2. Hollow arrow: indicates the flow of low-pressure lubricant.

3. Dark area: indicates the high-pressure lubricant.

4. Bright area: indicates the low-pressure lubricant.

1 - Oil Filler Cap

2 - Cylinder Head

3 - Oil Pressure Switch

4 - Oil Filter

5 - Cylinder Block

6 - Oil Pump

7 - Engine Oil

8 - Drain Plug

9 - Oil Strainer

10 - Oil Pan

11 - Crankshaft

1

2

3

4

6

5

7

11

9

8

10

RT21130020