Chery Tiggo 5 (T21). Manual - part 128

07–

98

07

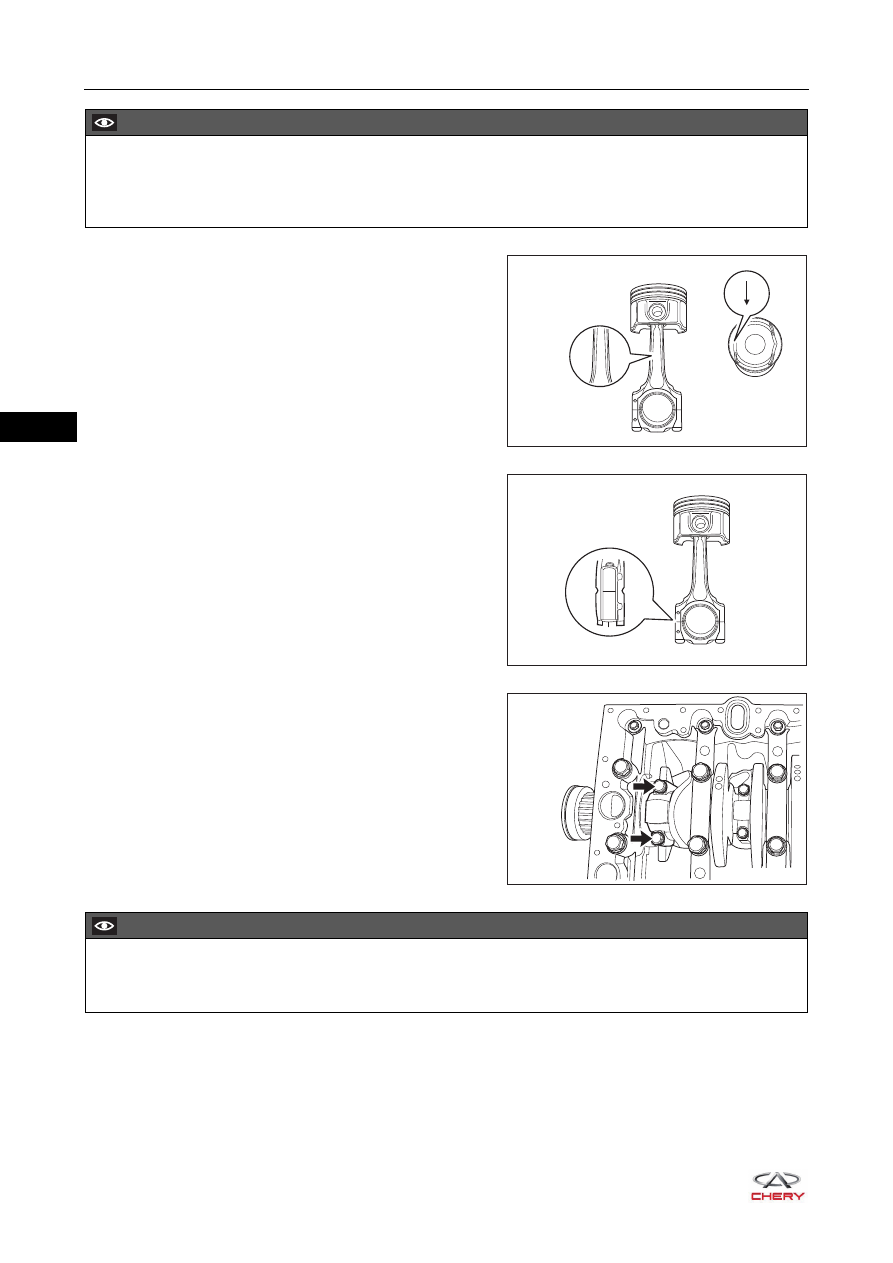

7. Install the connecting rod bearing cap.

HINT:

The direction of the number on one side of connecting

rod is the same as that of the number on the connecting

rod bearing cap. These numbers are cylinder numbers

indicating at which cylinder are located. For example,

number 3 indicates that the mounting position is at No.3

cylinder.

a. Install the connecting rod bearing cap in place, and

screw the connecting rod bearing cap fixing bolts

(arrow) by hands, then tighten the connecting rod

bearing cap fixing bolts in two steps.

(Tightening torque: 1st step: tighten to 25 ± 3 N·m;

2nd step: retighten for 90° ± 5°)

8. Other assembly is in the reverse order of disassembly.

CAUTION

Pay attention to the front marks of piston and connecting rod during assembly without being reversed.

Install them with the side stamped with letter "481HK" on the connecting rod and piston top arrow facing

toward timing belt side as shown in the illustration.

481HK

RT21071270

481HK

481HK

RT21071280

3

3

RT21070950

CAUTION

Apply a small amount of engine lubricant to the connecting rod, connecting rod bearing cap and thread

joint surface.