Loader Bobcat 853, 853H. Manual - part 50

ALTERNATOR

Removal And Installation

•

Engine is operated with battery cables

disconnected.

•

Battery cables are connected when using a

fast charger or when welding on the loader

(Remove both cables from the battery).

•

Extra battery cables (booster cables) are

connected wrong.

Damage to the alternator can occur if:

I–2023–1285

NOTE: The engine/hydrostatic pump assembly is

shown removed for photo clarity purpose

only.

Raise the operator cab. (See Page 1–1.)

Open the rear door. Disconnect the negative (–) battery

cable.

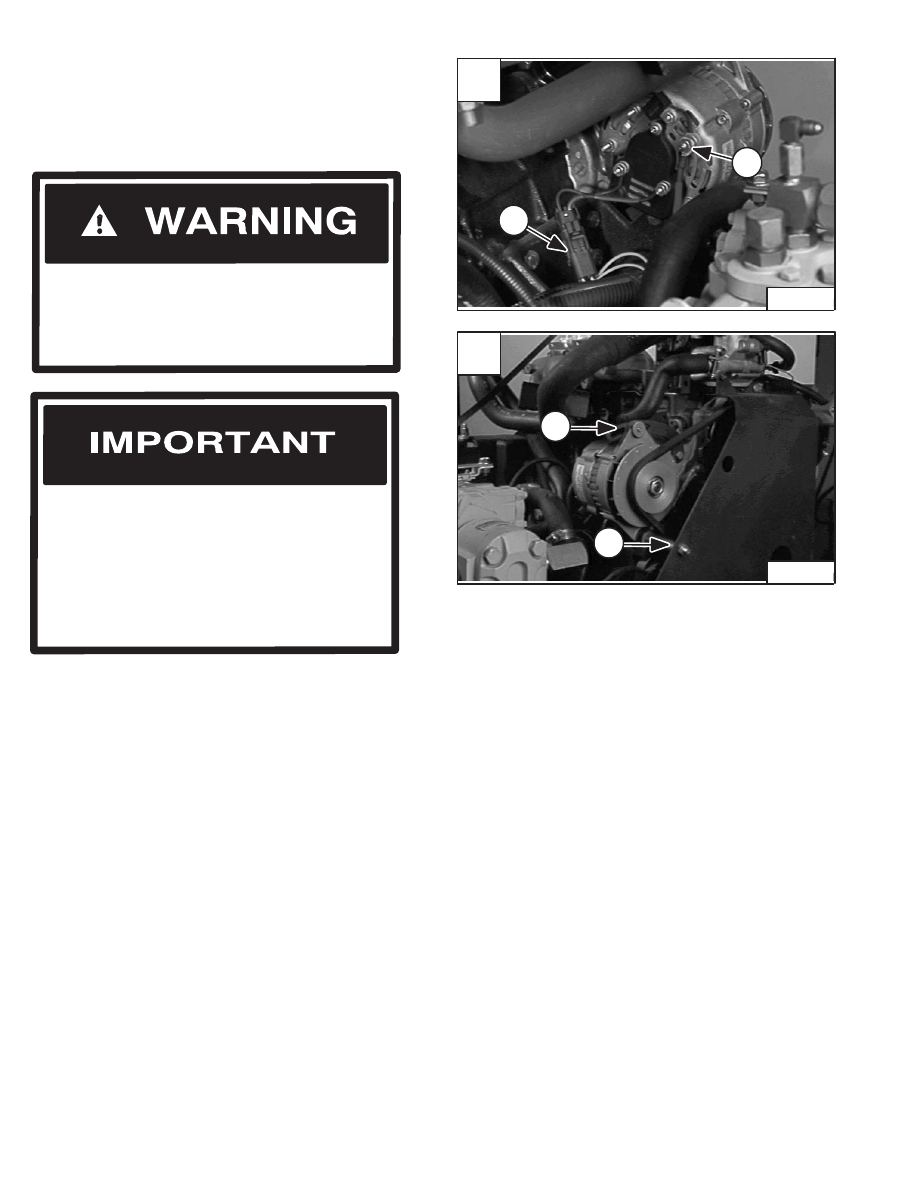

Disconnect the orange wire (Item 1) [A] from the

alternator.

Disconnect the wiring harness connector (Item 2) [A].

Loosen the adjustment bolt (Item 1) [B].

Remove the alternator belt.

Remove the adjustment bolt (Item 1) [B].

Remove the mounting bolt, nut and spacer (Item 2) [B].

Remove the alternator.

Never work on a machine with the lift arms up

unless the lift arms are secured by an approved

lift arm support device. Failure to use an

approved lift arm support device can allow the

lift arms or attachment to fall and cause injury

or death.

W–2059–0598

A

P–04944

2

1

–6–12–

853, 853H Loader

Service Manual

B

P–04945

2

1