Loader Bobcat 773. Manual - part 121

BICS

™

VALVE (Cont’d)

Removal And Installation

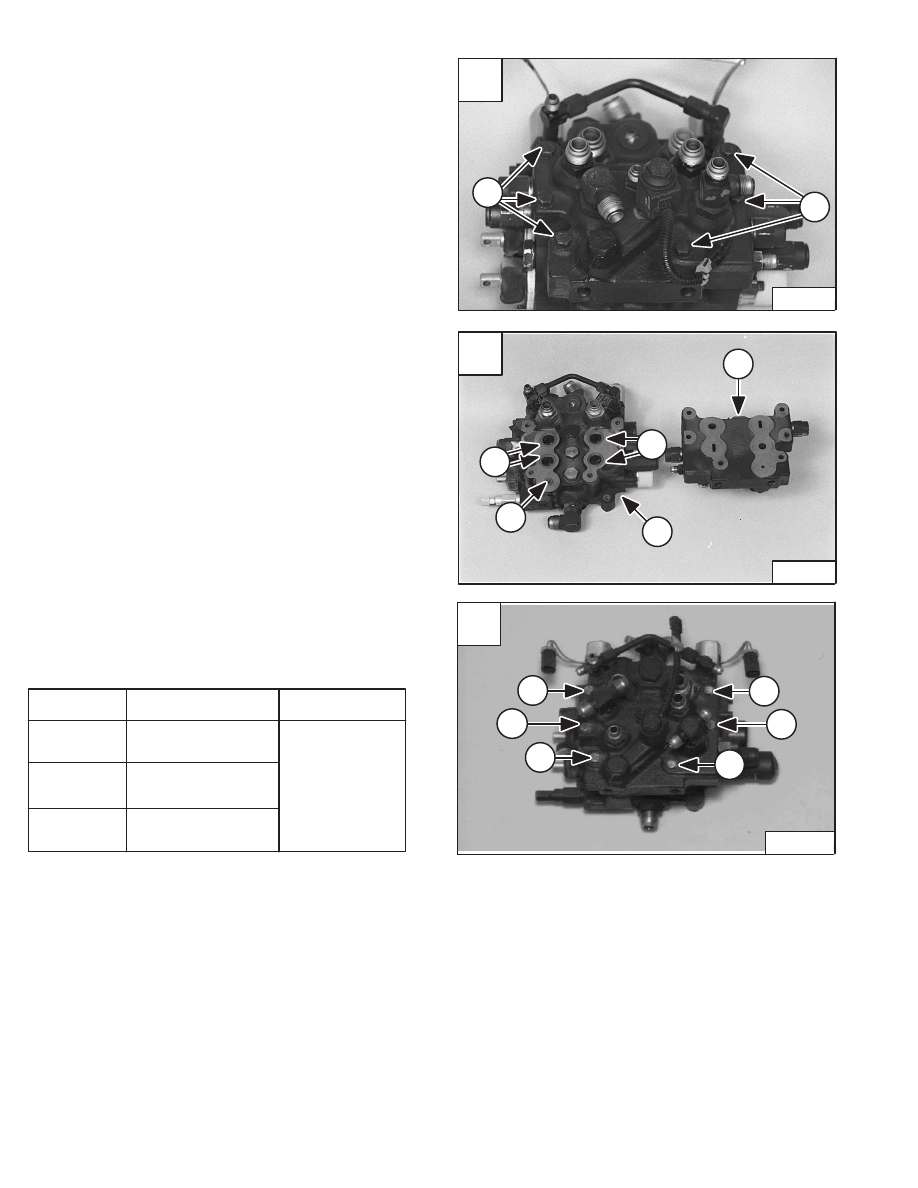

Loosen the six mounting bolts (Item 1) [A] at the BICS

valve.

Remove the mounting bolts (Item 1) [A].

Remove the BICS valve assembly (Item 1) [B] from the

top of the control valve (Item 2) [B].

Installation: Always replace the four large O–rings (Item

3) [B] and small O–ring (Item 4) [B].

Installation: The chart below lists the correct torque

specifications and tightening sequence [C] when

reinstalling the BICS

™

valve assembly to the hydraulic

control valve. Thoroughly clean and dry bolts and threads

in valve. Use liquid adhesive LOCTITE #242.

Step

1

2

3*

Torque

110–130 in.–lbs.

(12,4–14,7 Nm)

190–210 in.–lbs.

(21,5–23,7 Nm)

190–210 in.–lbs.

(21,5–23,7 Nm)

♦

Sequence

1, 2, 3, 4, 5 & 6

*Torque must be 190–210 in.–lbs. (21,5–23,7 Nm) for

every bolt or the complete

♦

sequence must be repeated.

A

N–17271

1

1

C

P–09587

3

1

5

6

2

4

–10–48–

Service Manual

773 BICS Loader

Revised June 01

B

N–17302

1

2

3

3

4