содержание .. 257 258 259 260 ..

Audi TT (2007 year). Manual - part 259

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

13

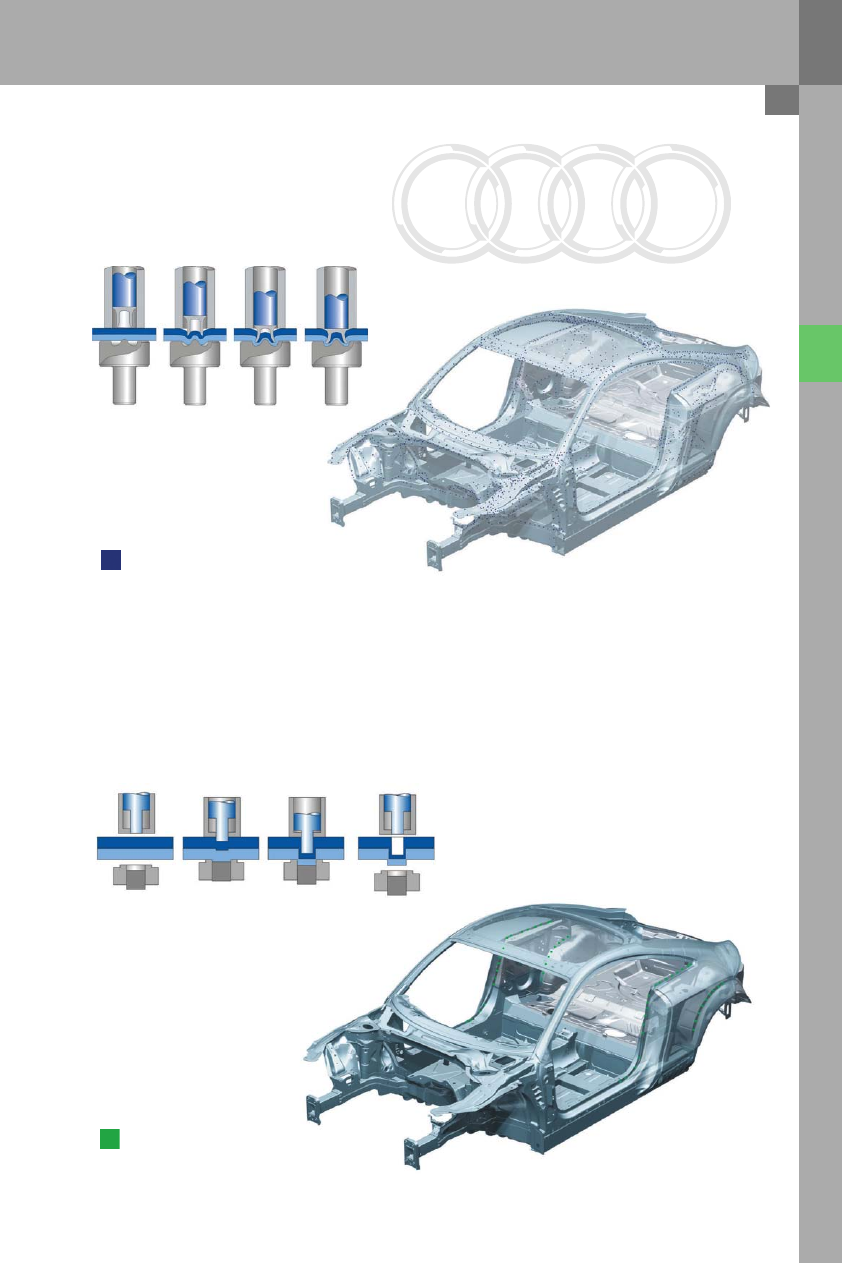

Punch riveting

Punch riveting is one of the principal joining techniques used on the bodyshell of the new Audi TT. This tech-

nique is used for joining aluminium body parts and for joining aluminium body parts to steel body parts.

The process has been in use since launch of the Audi A2. Self piercing rivets with two different diameters and

lengths are used in the Audi TT.

Punch riveting process

383_051

Applications of punch riveting

With clinching, the metal sheets to be joined are clamped between a die and a blankholder. The sheets are

then pushed down into the die by a punch to form an interlocking joint. However, joints produced in this way

is not as strong as joints produced by punch riveting, for example.

In the Audi TT, this technology is used on attachments such as doors and lids. Several clinched joints are also

located in the area of the B-post and rear wheel arch. In this area, aluminium sheets as well as steel and alu-

minium sheets are clinched together.

Applications of clinching

383_053

Clinching process

Clinching

383_052

383_032