Lotus Elise / Lotus Exige. Manual - part 104

Lotus Service Notes Section QH

Page 6

QH.4 - CLUTCH ASSEMBLY

The clutch assembly comprises the friction plate, clutch cover assembly (pressure plate/diaphragm spring/

cover) and release bearing. For access to the clutch assembly, the engine and transmission must be sepa-

rated.

Removal of clutch assembly:

The transmission may be removed from below:

1.

Remove the LH rear suspension assembly (refer to sub-section DH.3), both driveshaft assemblies (refer

to sub-section FJ.4) and the exhaust system.

2.

Disconnect the clutch release fork, gearchange cables, earth braid and reverse light switch.

3.

The engine must be supported to allow the engine and transmission mountings to be disconnected and

the power unit tilted as necessary to allow the transmission to be withdrawn. The clutch bell housing is

secured to the engine by 8 bolts as shown overleaf.

4.

Matchmark the clutch cover to the flywheel before progressively loosening each clutch cover bolt half a

turn at a time until clutch cover spring pressure is released. Withdraw the cover from the flywheel dowels

taking care not to allow the friction plate to drop.

5.

Pull the release fork off the fork pivot ball, and withdraw fork and release bearing from the transmission.

Inspection

1.

Clutch cover: Check the surface of the pressure plate for scoring or discolouration through overheating.

Check the fingers of the diaphragm spring for excessive wear at the release bearing contact surface. If

any fingers are indented to a width greater than 6mm, or a depth of 0.5mm, the cover assembly should be

renewed. If the cover is accidentally dropped, the setting or balance of the assembly could be disturbed.

Replacement of the cover is recommended.

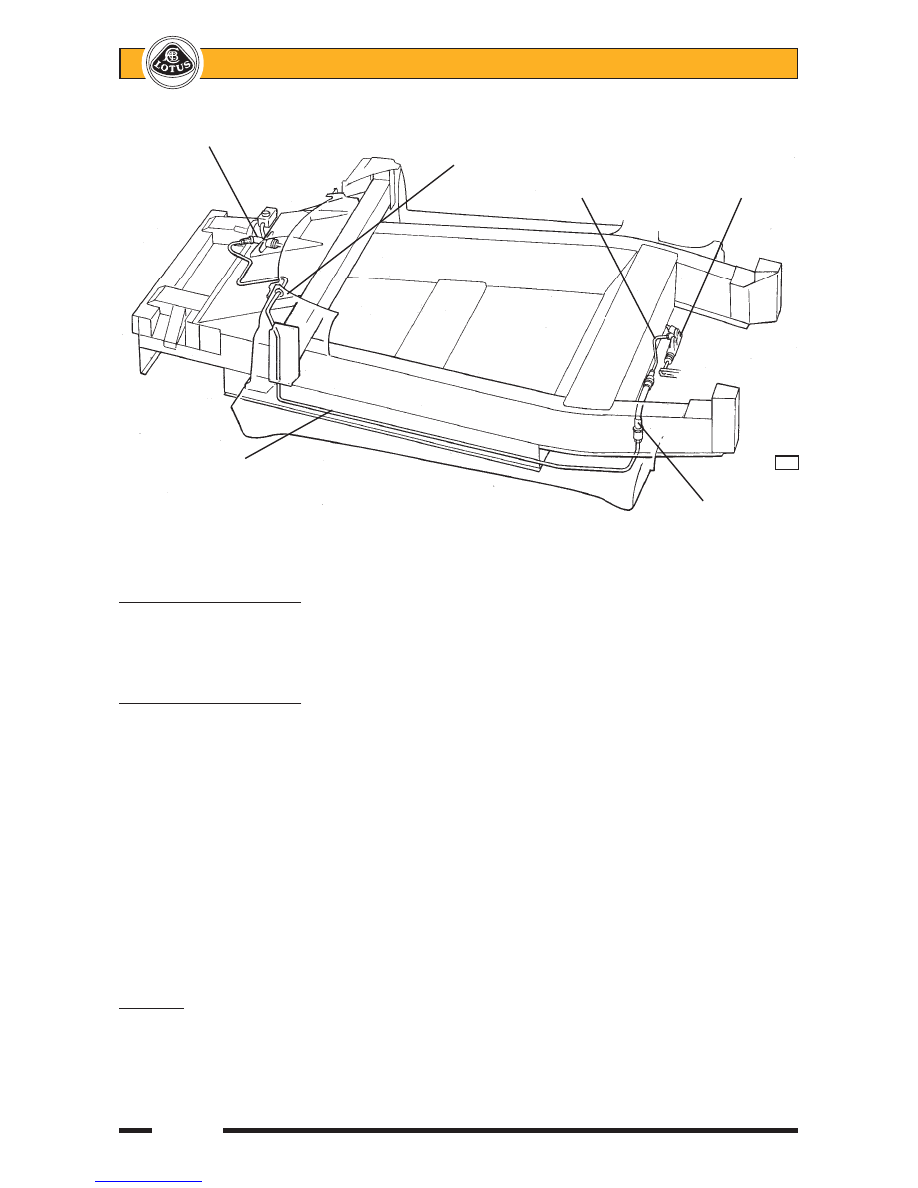

Clutch master cylinder

Dash baffle panel

Steel pipe

Slave cylinder

Steel pipe clipped

q46a

to heater pipe

Flexible hose

to engine