Lotus Elise / Lotus Exige. Manual - part 56

Lotus Service Notes

Section JJ

Page 7

Tools Required:

Piston Retraction Tool T000T1242

1.

Remove the rear road wheels.

2.

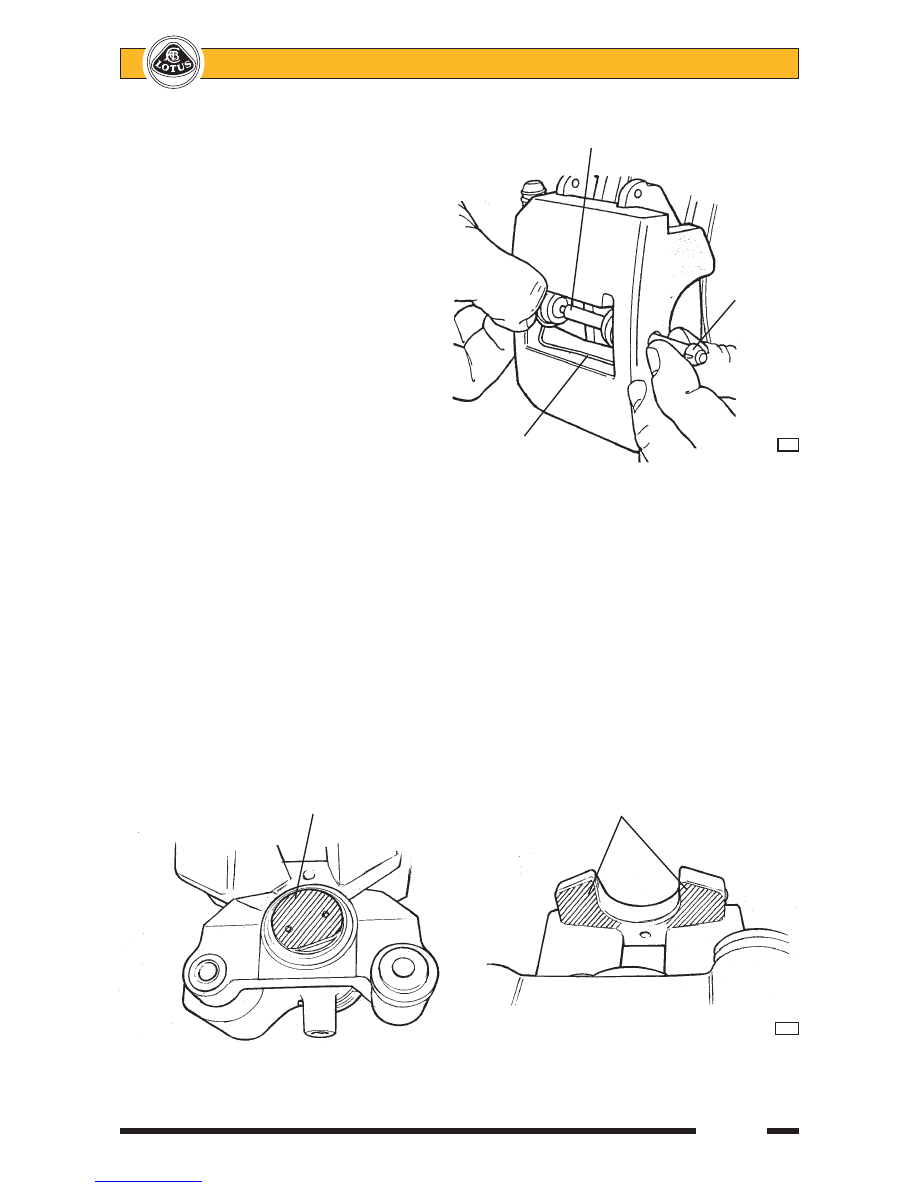

At each rear corner: using a suitable pin

punch, knock the pad retaining pin out

of the calliper towards the outside, tak-

ing precautions as necessary to restrain

the anti-rattle spring from flying off as

the pin is withdrawn.

3.

Remove the anti-rattle spring, and with-

draw both brake pads from the calliper.

Measure the thickness of the lining ma-

terial, and renew the axle set of pads if

any are below 2.5 mm.

4.

Before refitting the pads, inspect the pis-

ton boot for splits, cracks or other dam-

age, and for any signs of fluid leakage

or wetness.

If any such signs are apparent, the complete calliper should be replaced as Brembo do not recommend

that this calliper be dismantled.

5.

If refitting the existing brake pads, refit each pad in the same position as originally fitted.

6.

Before fitting new rear pads, the calliper piston must be screwed back into the calliper down the parking

brake actuation mechanism. This operation requires the use of special tool T000T1242 and the removal

of the brake disc:

-

Remove the single socket head screw retaining the brake disc, and remove the disc.

-

Fit special tool T000T1242 into the holes in the calliper piston, and screw the piston back down

the parking brake mechanism screwthread until fully bottomed.

-

Refit the brake disc, and tighten the countersunk retaining screw to 12 Nm.

7.

In order to minimise brake squeal from new pads during the bedding-in period, a copper based (PBC)

paste (e.g Renolit) should be used on the pad contact surfaces of the rear callipers in the areas shown:

Pad retaining pin

Retaining

pin snap

ring

Anti-rattle spring

j123

Contact face of piston

Calliper outboard fingers

j188