Lotus Eleven/Elise/Exige. Manual - part 76

Lotus Service Notes

Section LJ

Page 7

9.

Ensure the pump/sender unit is fitted into the into the tank, with the earth braid fitted onto the '10 O'clock'

position pump mounting stud.

10.

Loose fit the LH tank mounting cradle ensuring that the earth braid is fitted beneath the head of the

horizontally disposed front fixing bolt.

11.

Feed the LH end of the tank into the cradle, and raise the tank into position taking care not to trap or pinch

the fuel pipes or wiring harness. Retain with the RH cradle, noting that no washer is fitted at the horizon-

tally disposed front fixing point. Torque tighten the cradle fixing bolts to 24 Nm.

12.

Continue the installation in reverse order to removal, and ensure that the 'shear panel' is fitted beneath

the fuel tank bay before driving the car.

LJ.5 - FUEL PUMP/SENDER ASSEMBLY

The combined fuel pump/gauge sender unit is mounted in the left hand end of the tank top surface. A

removeable panel is provided in the top of the chassis crossmember in the cabin, which provides access to the

fuel pipe connections and harness connector, but if the pump/gauge sender unit is to be replaced, the tank

must be removed from the chassis (see sub-section LJ.4).

For fuel pump test procedures, refer to Toyota 2ZZ-GE Engine Repair Manual, publication RM733E.

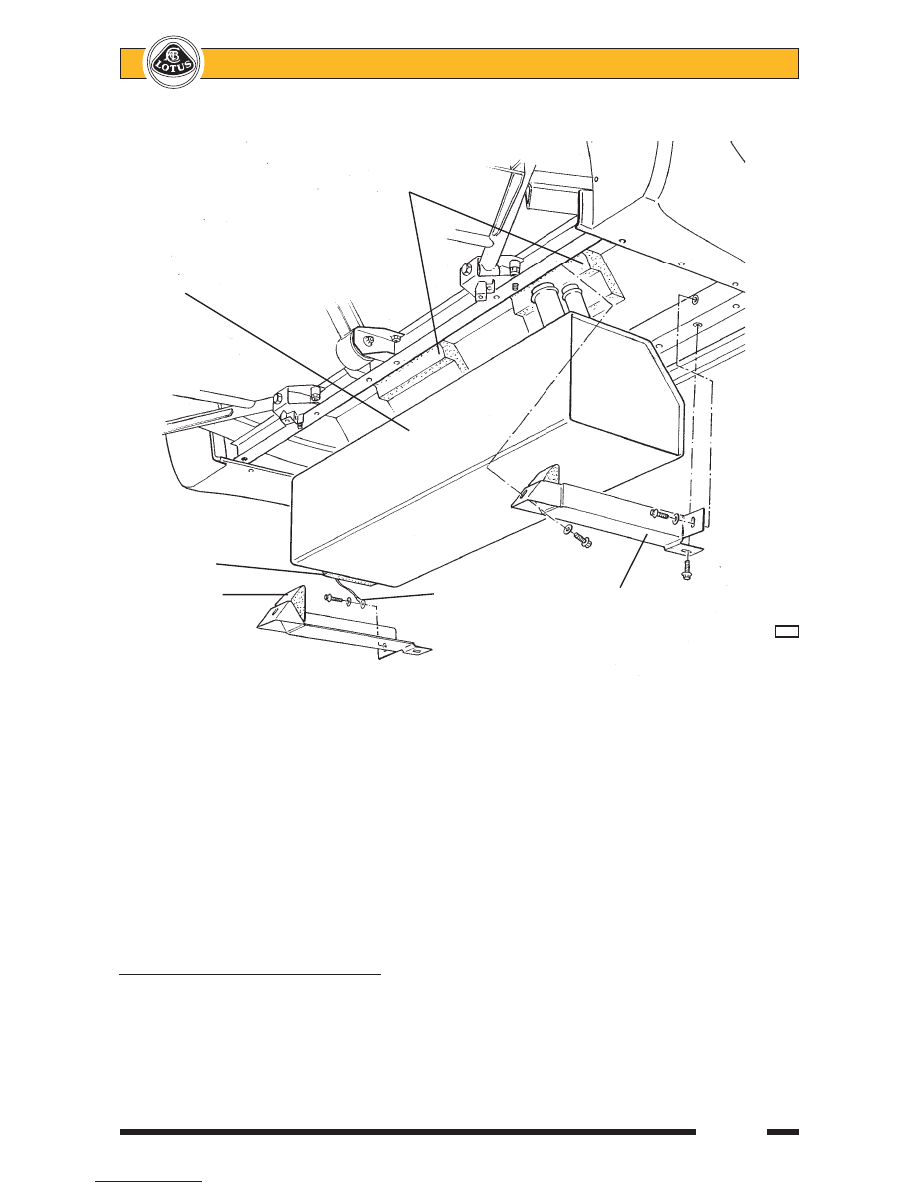

Polypropylene saddles

Fuel tank

Foam sponge

Rubber wedge

Earth braid

Support

cradle

L59b