Porshe 911 (997). Manual - part 56

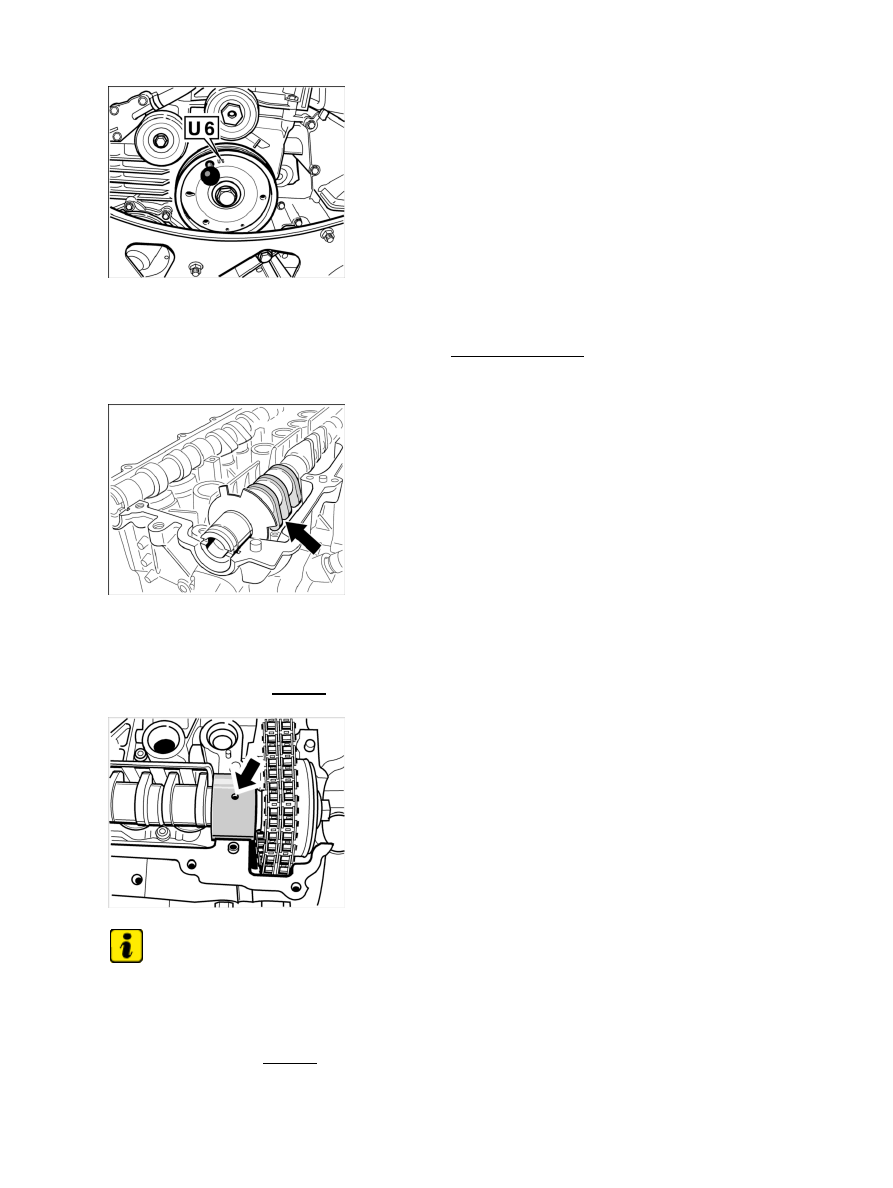

Pulley fixed at 60° before TDC

23. Turn the crankshaft by means of the pulley or vibration balancer clockwise (running direction of

engine

further still until the marking U6 on pulley or vibration balancer coincides with fixing

bore in crankcase

(60° before TDC). Fix with locating pin 9595/1.

24. Oil the bearing surfaces of the camshafts with new engine oil.

Inlet camshaft 1-3 in overlap

25. Insert inlet camshaft 1 - 3. Pull the control chain out of the chain housing of the cylinder head with a

welding wire and position on the toothed ring of the camshaft adjuster. Then insert the camshaft at

overlapping TDC of cylinder 1 (the cams of cylinder 1 point diagonally downwards towards the outside

of the cylinder head -arrow- ).

Position of bearing sleeve for inlet camshaft

Note

Make sure that the bearing sleeve on the inlet camshaft is positioned correctly.

•

26. The bearing sleeve of the inlet camshaft must be positioned so that the centrally bored blind hole points

vertically upwards -arrow- (the rib of the cylinder head should also be at the centre in relation to the

bearing sleeve). In this position, the dowel pin in the bearing bore of the cylinder head will fit precisely

Diagnostic system: reading out fault memory and activating systems

Installing camshafts, adjusting timing - engine removed

381