Snowmobile Arctic Cat (2008 year). Manual - part 158

8-35

8

INSPECTING

NOTE: Whenever a part is worn excessively,

cracked, or damaged in any way, replacement is

necessary.

1. Inspect the arm welded areas for cracks or any

signs of deterioration.

2. Inspect the bearings and axles for wear or dam-

age.

3. Inspect the arm tubing for signs of twisting or

bending.

INSTALLING UPPER ARMS

1. With the axles properly installed as noted during

removing, install the upper arms to the chassis;

then secure the arms with the cap screws and lock

nuts. Tighten to 32 ft-lb.

2. With the axle installed in the spindle, secure the

upper arms to the spindle with the cap screw and

lock nut. Tighten to 32 ft-lb.

REMOVING LOWER A-ARM

NOTE: To remove the lower A-arms, it will be

necessary to remove the air silencer. Proceed to

Air-Intake Silencer (Liquid-Cooled F-Series/T-

Series Models) sub-section in Section 4 and follow

REMOVING procedure.

1. Elevate the front of the snowmobile with a suitable

safety stand or lift.

2. Remove the cap screw and lock nut securing the

shock absorber to the spindle; then remove the

shock from the spindle and account for the shock

sleeve.

3. Remove the four torx-head cap screws securing

the lower A-arm bearing cap to the spindle; then

remove the cap and lower arm from the spindle.

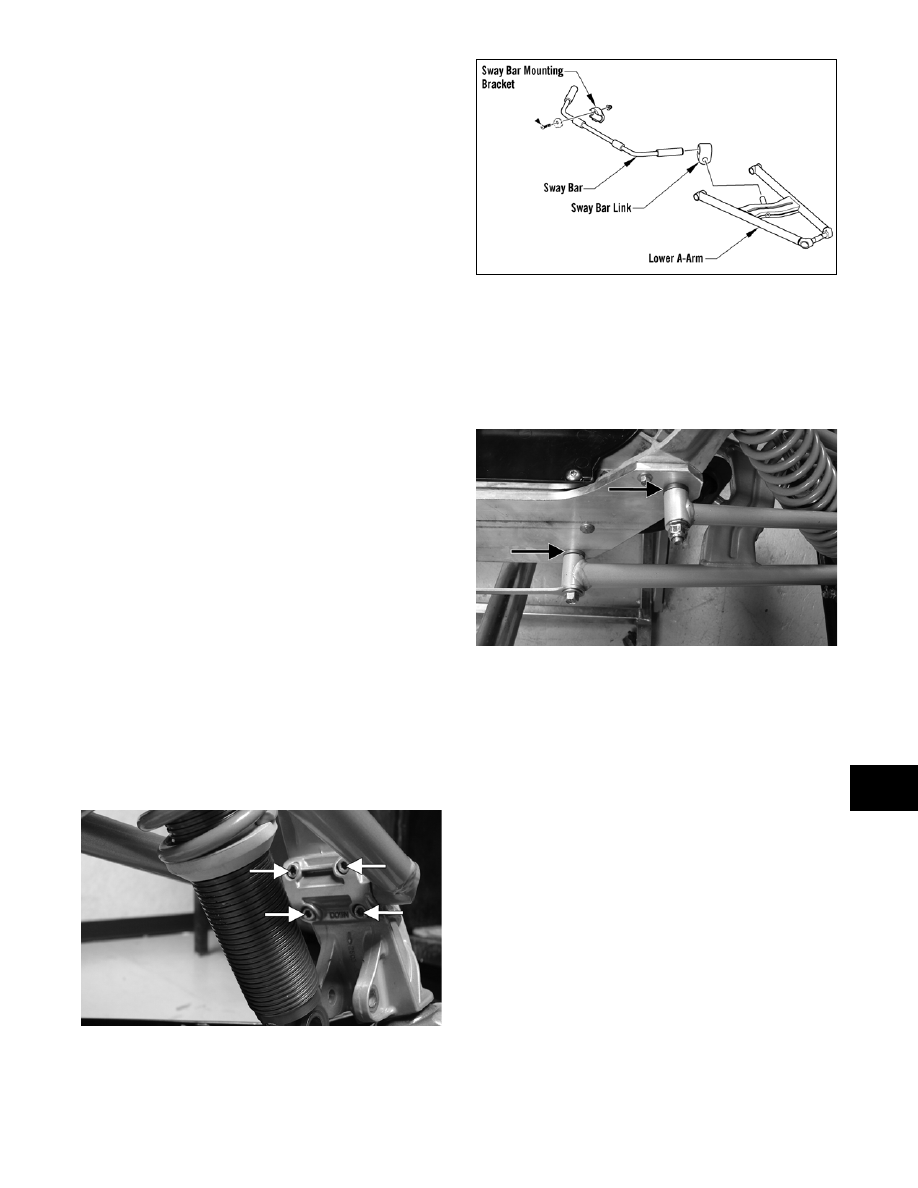

ZJ174A

4. Secure the upper arms and spindle out of the way;

then remove the sway bar/link from the lower arm.

0742-219

5. Remove the cap screws and lock nuts securing the

lower A-arm to the chassis; then remove the arm

from the sway bar and chassis and account for the

axles.

NOTE: For installing purposes, note the posi-

tion of the axle shoulders.

ZJ168A

6. If applicable using a flat-blade screwdriver, pry

the split bearings from the spindle axle of the A-

arm.

NOTE: The split bearings cannot be reused;

they must be replaced with new ones.

INSPECTING

NOTE: Whenever a part is worn excessively,

cracked, or damaged in any way, replacement is

necessary.

1. Inspect the arm welded areas for cracks or any

signs of deterioration.

2. Inspect the bearings and axles for wear or dam-

age.

3. Inspect the arm tubing for signs of twisting or

bending.