Snowmobile Arctic Cat (2008 year). Manual - part 149

7-156

FS016

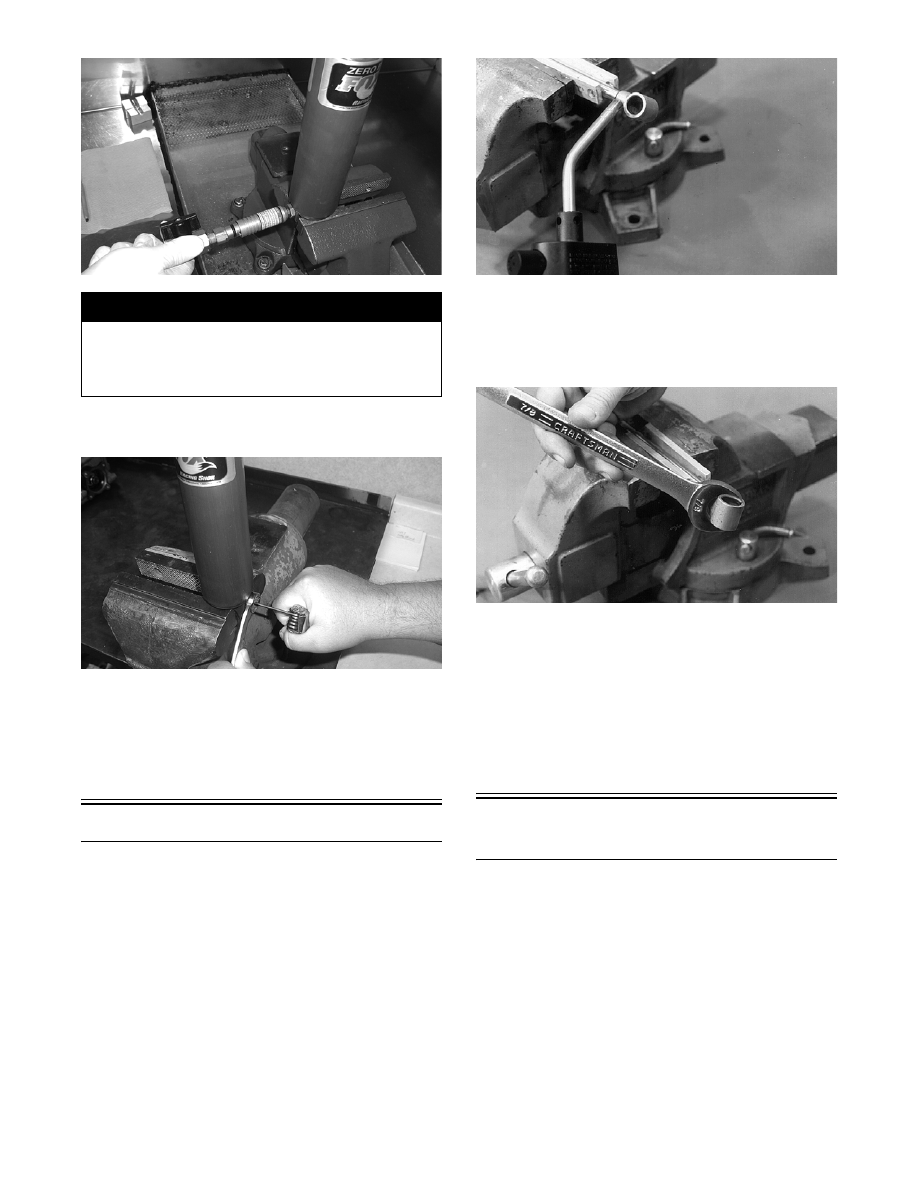

22. Install the button-head screw into the nitrogen

valve.

FS040

23. Clean all oil residue from the shock and reservoir

with solvent and dry with compressed air in a well

ventilated area.

24. Install the polyurethane bushings and steel sleeves

into the eyelets.

Shaft Eyelet

REMOVING

1. Using Shock Rod Clamping Tool to prevent dam-

age to the shaft surface, place the shock shaft into

a vise.

2. Heat the shaft eyelet with a torch to soften the

Loctite.

AG260

NOTE: The eyelet must be heated up to 300° for

the Loctite to soften.

3. Using a wrench, unscrew the eyelet from the shaft.

AG261

NOTE: With the eyelet removed, inspect the bot-

tom-out bumper for cracks or wear.

INSTALLING

1. Clean shaft threads and eyelet threads.

2. Apply red Loctite #271 to both threads, install the

eyelet, and tighten securely.

Pressurizing

Rebuildable Shocks

To pressurize the gas shock absorber, a regulator sys-

tem and a nitrogen tank will be needed.

! WARNING

Charge the shock using nitrogen gas only. DO NOT

CHARGE WITH ANY OTHER TYPE OF GAS. Doing so

will compromise the performance of the shock and

may be EXTREMELY DANGEROUS.