Snowmobile Arctic Cat (2008 year). Manual - part 60

2-178

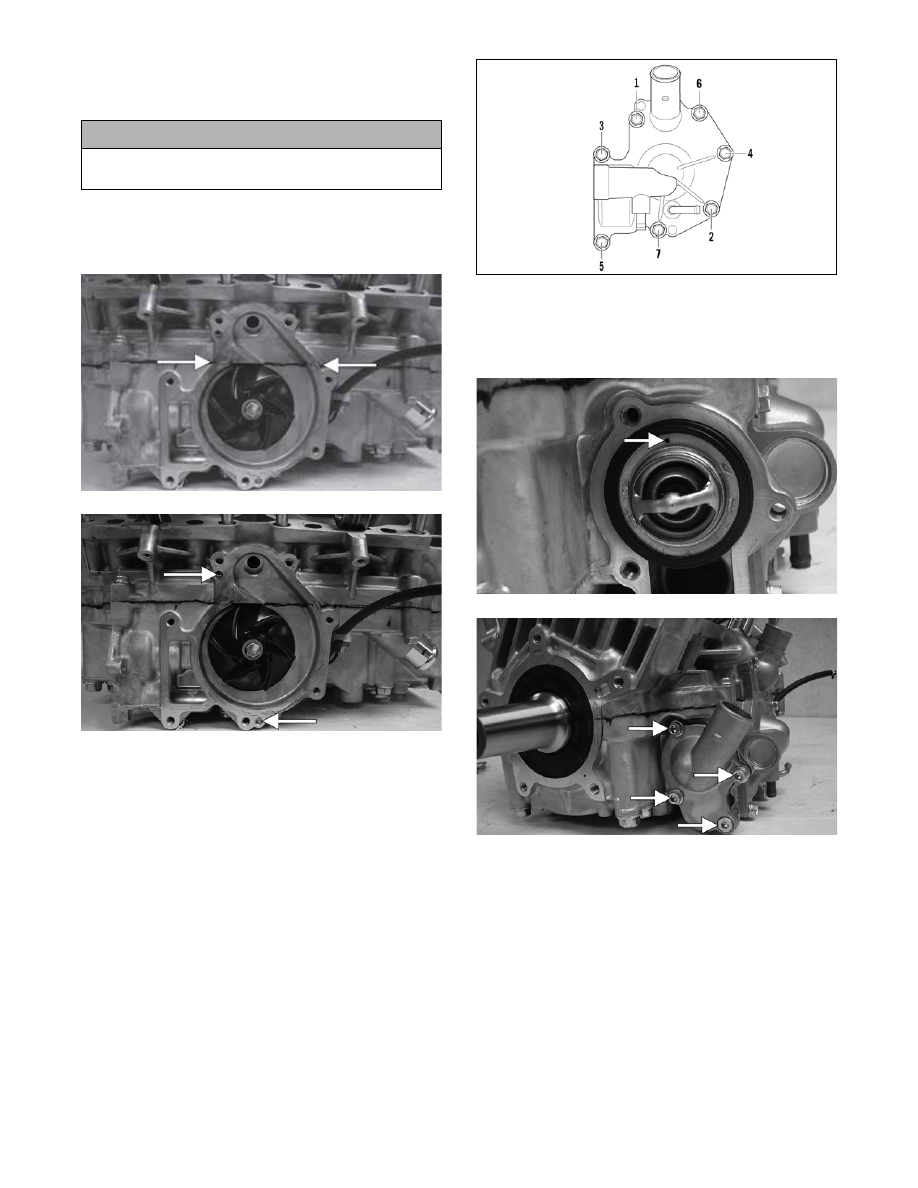

NOTE: For assembling purposes, it is advisable

to lubricate the rubber side of the washer before

installing.

25. Apply high-temperature sealant to the crankcase/

water pump cover seam; then install the dowel

pins into the crankcase.

CM171A

CM171B

NOTE: Sealant is only required on the crankcase

seam.

26. Apply a thin film of low-temp grease to the water

pump cover O-ring; then position the O-ring into

the water pump cover. With the alignment pins in

place, install the cover. Secure with seven screws

using the pattern shown. Tighten to 8 ft-lb.

0742-257

27. With the bypass valve of the thermostat directed to

the 12 o’clock position, install the thermostat and

housing; then in a crisscross pattern, tighten the

cap screws to 8 ft-lb.

CM157A

CM155A

28. Place the cylinder base gasket into position on the

crankcase.

29. Install the piston rings on each piston so the letter

on the top (inclined surface) of each ring faces the

dome of the piston.

! CAUTION

If the rubber side of the washer is not positioned

toward the impeller, a coolant leak will result.