Snowmobile Arctic Cat (2008 year). Manual - part 47

2-125

2

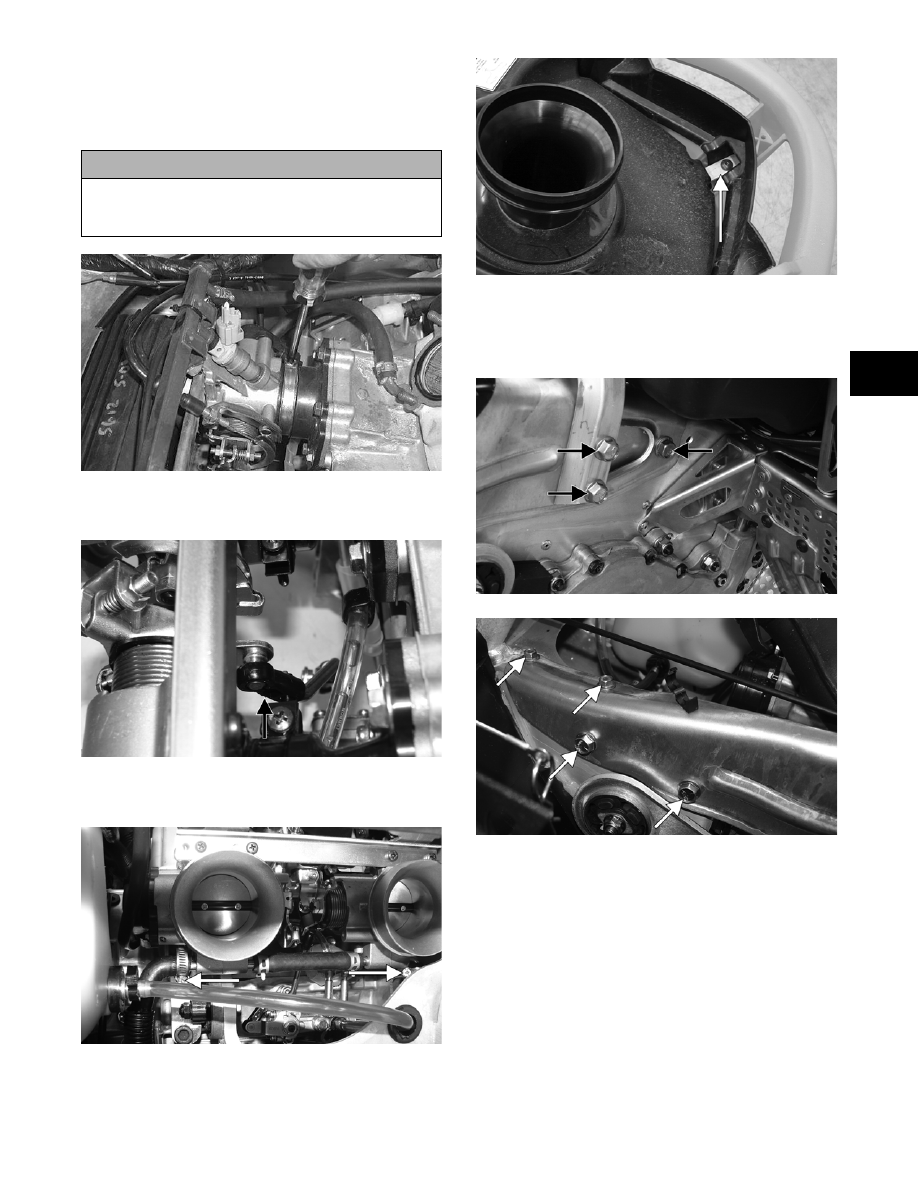

14. Place the throttle bodies into position and secure

with the flange clamps. Verify oil-injection pump

synchronization (see Section 4); then connect the

fuel line to the throttle body assembly and tighten

the clamp securely.

FC051

15. Install the oil pump linkage arm to the throttle

body pulley.

CM129B

16. Connect the two coolant hoses to the throttle body

assembly; then secure with the clamps.

CM131A

17. With the air silencer boot properly positioned on

the throttle body assembly, install the silencer and

secure with the hold-down and the torx-head cap

screw.

CM026A

18. Install the side-plate brace onto the chassis and

secure the brace and the steering support with the

cap screws (coated with blue Loctite #243).

Tighten securely.

CM132A

CM133A

NOTE: It is advisable to install the two front lower

cap screws first to attain proper alignment for the

remaining cap screws.

! CAUTION

When installing the throttle bodies, make sure the

gasline hose is properly routed to avoid premature

wear and/or contact with exhaust components.